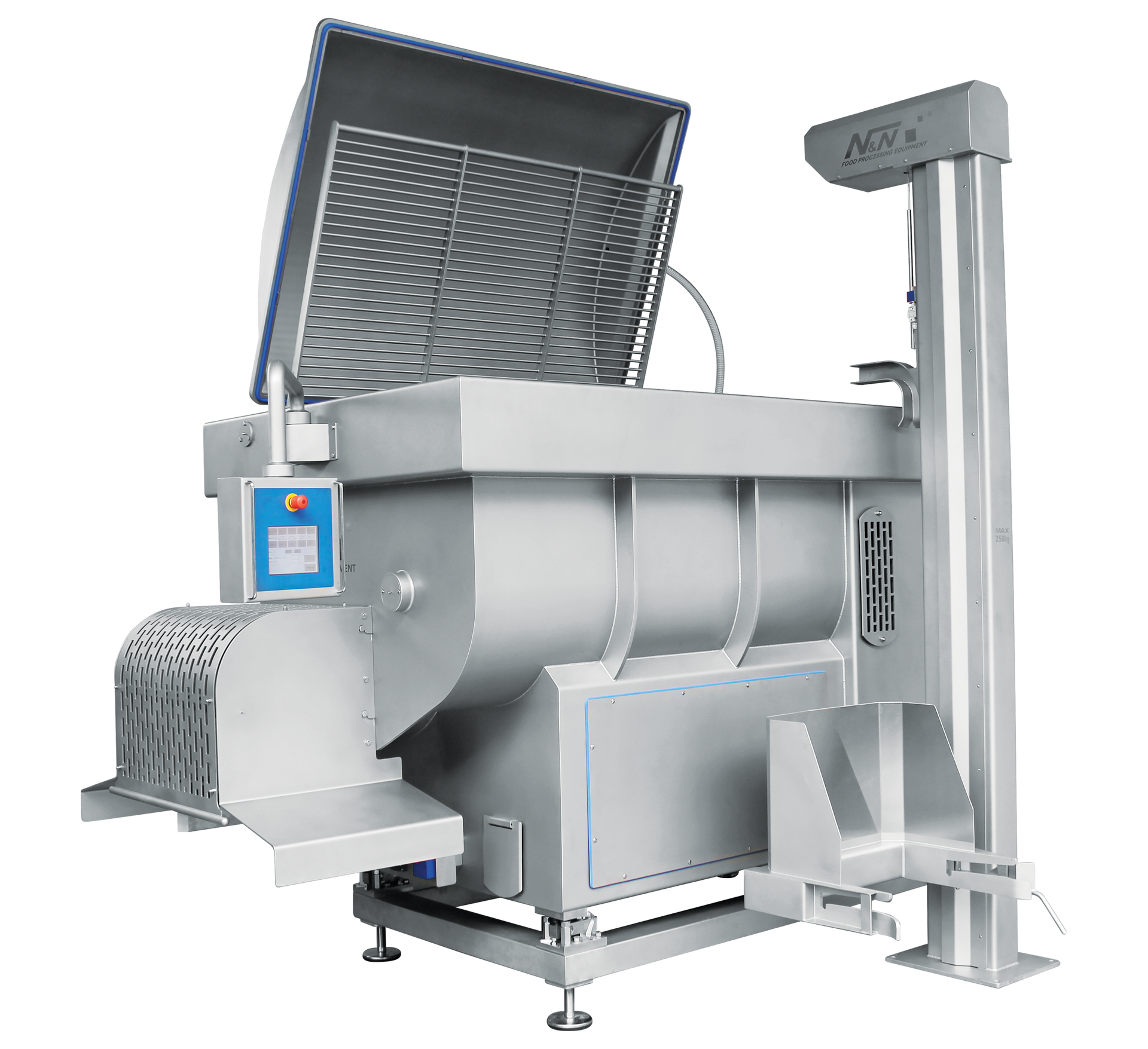

Series W

Industrial Angle Grinders for Food Processing

Hopper Capacity

110 - 1,200

Liters

Throat Diameter

5.1 - 11

Inches

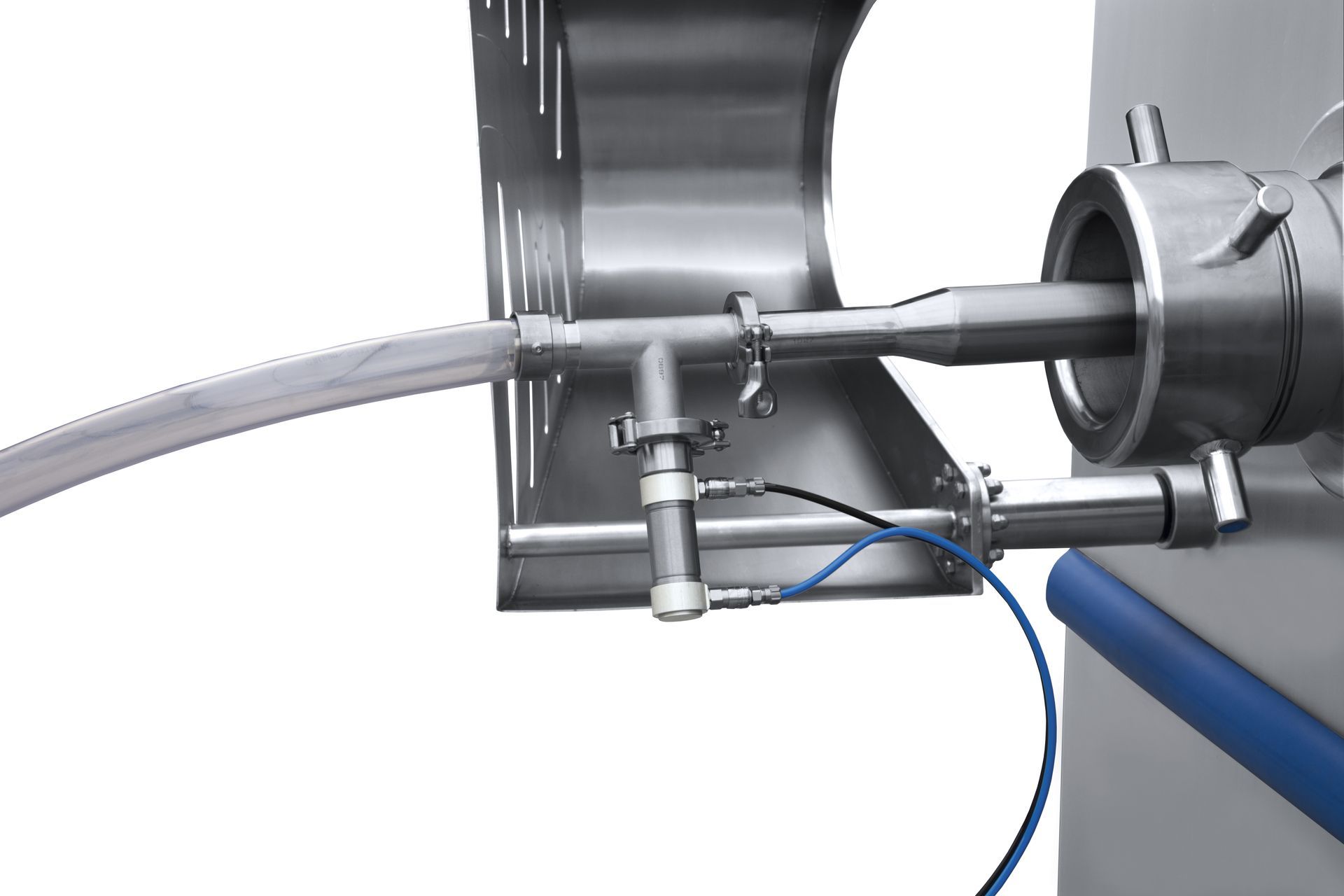

- Angled Auger System: Features two angularly arranged augers—a feeding auger and a pressing auger—designed for efficient performance. It utilizes high quality cutting tools in various configurations, combined with adjustable feeding speed to meet diverse processing needs.

- Capability of Grinding Frozen Blocks (B- Series): Combines the ability to grind fresh products with the capability to grind frozen blocks at temperatures as low as -7°F.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments. Augers are constructed from a single piece of metal, eliminating the need for welding.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs by adjusting variables such as the speed of the feeding and grinding/pressing augers.

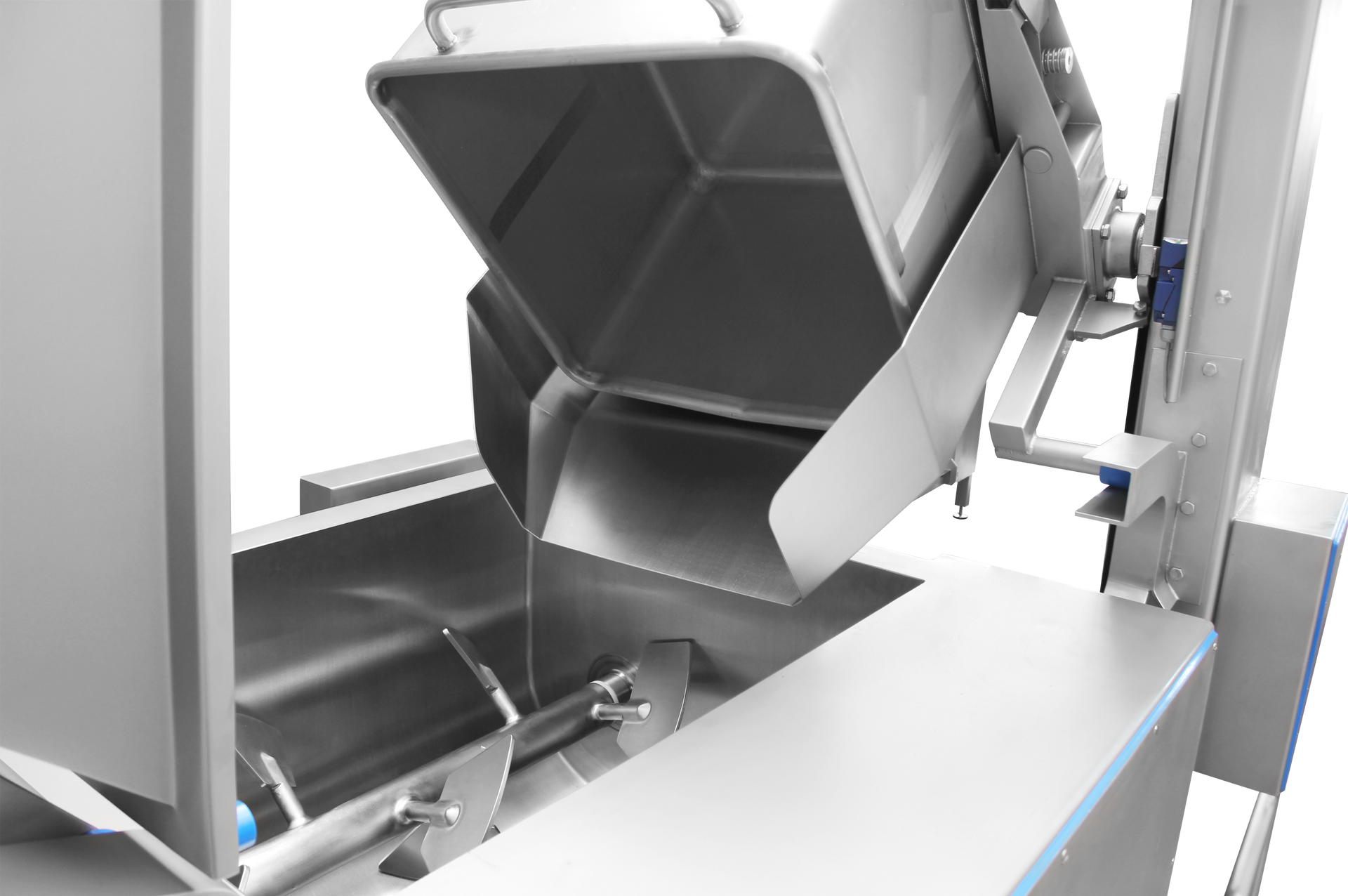

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

W

W B (Frozen Block Grinders)

Applications

NOMA Angle Grinders are designed for grinding a variety of products including proteins, vegetables, fruits and any other solid for the food processing industry. For wide use in the production of sausages, patties, pet food, and other processed meat products.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Industrial Angle Grinders

What is an industrial angle grinder in food processing?

Industrial angle grinders are heavy-duty food processing machines specifically engineered for grinding proteins, vegetables, fruits, and other solids within large-scale food production environments. Unlike tools used in other industries, these grinders are purpose-built for food applications, ensuring hygienic processing and consistent results. BAK Food Equipment’s angle grinders are constructed entirely from stainless steel, providing exceptional durability and easy cleaning, which is essential for maintaining food safety standards. These machines are available in a range of sizes and capacities, with hopper volumes from 110 to 1,200 liters and throat diameters up to 11 inches, making them suitable for both small and high-capacity operations.

How do angle grinders differ from straight grinders?

The primary distinction between angle grinders and straight grinders in food processing lies in the auger configuration. Angle grinders utilize an angled auger system, where the feeding and pressing augers are arranged at an angle to each other. This design improves the flow of product through the grinder, reduces the risk of clogging, and enhances overall throughput. The angled design also has the ability to be more delicate with the product which improves product definition. In contrast, straight grinders typically use a single, linear auger, which may not be as effective for high-capacity or multi-ingredient applications. The angled system allows for more precise control over the grinding process, especially when dealing with a variety of product types, from fresh meat to frozen blocks and mixed ingredients.

Why are angle grinders essential for large-scale food production?

Angle grinders are indispensable in large-scale food production due to their versatility, efficiency, and ability to handle a wide range of products. They are commonly used for grinding fresh meat, frozen blocks, poultry, seafood, vegetables, and even pet food. The advanced programmable control panels on BAK Food Equipment’s angle grinders allow operators to customize and store programs, adjusting variables such as auger speed to meet specific processing needs. This flexibility supports the production of sausages, patties, and other processed foods at high volumes. Additionally, features like bone/tendon separators and optional loading systems further streamline operations, reduce manual labor, and ensure consistent product quality. The combination of high-capacity performance, adaptability, and ease of maintenance makes industrial angle grinders a cornerstone of modern food processing lines.

Key Features of Series W Angle Grinders

What makes the Series W Angle Grinders unique?

The Series W Angle Grinders from BAK Food Equipment stand out in the food processing industry due to their robust design, versatility, and advanced engineering. These grinders feature a two auger system that are at an angle—a feeding auger and a pressing/grinder auger—ensuring efficient and consistent product flow. The system is engineered to handle a wide range of products, including proteins, vegetables, fruits, and other solids, making it suitable for diverse applications such as sausage production, patties, pet food, and other processed meat products. The grinders are constructed entirely from stainless steel, with an auger design that eliminates welds, enhancing both durability and hygiene. This construction not only extends the equipment’s lifespan but also simplifies cleaning and maintenance, which is critical in food processing environments.

What technical specifications should buyers know?

Hopper capacities range from 110 to 1,200 liters, accommodating both small and high-volume production needs. Throat diameters are available up to 11 inches, allowing for the processing of large product volumes and sizes. The grinders are capable of handling both fresh and frozen products, with the W B-Series models specifically designed to grind frozen blocks at temperatures as low as -7°F. This flexibility makes the Series W ideal for operations requiring both fresh and frozen meat processing. The machines are also designed for easy integration into automated production lines, supporting efficient workflow and scalability.

How do optional features improve performance?

Optional features available for the Series W Angle Grinders further enhance their performance and adaptability. The bone/tendon separator is a key addition, efficiently removing tendons and tough tissues during grinding to improve product consistency and reduce manual labor. Automated loading options are also available, offering fixed, mobile, or free-standing configurations to streamline product transfer between processing stages. These options not only increase throughput but also support compliance with hygiene and safety standards by minimizing manual handling. The advanced programmable control panel, featuring an intuitive touch screen, allows operators to create and store custom programs, adjusting variables such as auger speed to optimize performance for specific recipes or product types. These enhancements make the Series W Angle Grinders a reliable choice for processors seeking high-volume, consistent, and hygienic grinding solutions in demanding industrial environments.

Applications of Industrial Angle Grinders

What products can be processed with angle grinders?

Industrial angle grinders, such as those offered by BAK Food Equipment, are engineered to handle a diverse range of food products. These grinders are commonly used for processing proteins—including beef, pork, poultry, and seafood—into ground meats for sausages, patties, and other processed meat products. Their robust design also makes them ideal for grinding pet food ingredients, ensuring a consistent texture and quality in finished products. Beyond meat, these grinders are capable of processing vegetables, fruits, and alternative proteins, making them a versatile solution for bakery and plant-based food processors. The ability to grind both fresh and frozen blocks (at temperatures as low as -7°F) further expands their application, supporting the production of specialty foods and meeting the needs of high-capacity operations.

Which industries use angle grinders most often?

Angle grinders are a staple in several key sectors of the food processing industry. High-volume meat processing plants rely on these machines for their efficiency and ability to maintain product consistency across large batches. Independent food producers also benefit from the flexibility and reliability of industrial angle grinders, which help them deliver uniform quality and flavor in their products. Sausage production grinders are necessary for optimal sausage production. The pet food industry utilizes specialized pet food grinders to process a variety of protein and non-protein ingredients, ensuring safety and palatability for companion animals. Additionally, bakery and plant-based processors use bakery grinders and vegetable grinding equipment to prepare ingredients for alternative proteins and specialty baked goods. Across all these industries, the use of advanced features—such as programmable control panels and optional bone/tendon separators—ensures that BAK Food Equipment’s grinders deliver precise, repeatable results while supporting streamlined, automated production lines.

Efficiency, Safety & Maintenance

How are Series W grinders designed for safe and efficient operation?

Series W angle grinders from BAK Food Equipment are engineered with both operator safety and processing efficiency in mind. The advanced programmable control panel features an intuitive touch screen, allowing operators to create and store custom programs by adjusting variables such as the speed of the feeding and grinding augers. This ensures consistent results and minimizes the risk of operator error. The design also supports compliance with USDA, FDA, and HACCP requirements, making these grinders suitable for food safety equipment applications. Additionally, the single-piece auger construction eliminates weak weld points, reducing the risk of mechanical failure and contamination, which further enhances operational safety and reliability.

What features make them easy to clean?

Hygiene is a top priority in food processing, and Series W grinders are thoughtfully designed for easy cleaning and maintenance. The use of single-piece augers not only improves durability but also eliminates crevices where food particles and bacteria could accumulate. The stainless steel construction resists corrosion and wear, making it easier to thoroughly sanitize all surfaces. Routine cleaning is straightforward, reducing downtime and supporting compliance with stringent food safety standards. These features make Series W grinders ideal as hygienic grinders and easy-clean industrial grinders in demanding production environments.

Why does stainless steel construction matter?

Stainless steel construction is critical in industrial food processing equipment due to its resistance to corrosion, wear, and chemical damage. In the Series W grinders, all major components are built entirely from stainless steel, ensuring long-lasting performance even in the most demanding environments. This material choice not only extends the lifespan of the equipment but also supports rigorous cleaning protocols required for grinder maintenance. Stainless steel surfaces are non-porous, which helps prevent the buildup of bacteria and other contaminants, making these grinders a reliable choice for maintaining food safety and product quality.

Choosing the Correct Angle Grinder for Your Facility

How do businesses decide between different Series W models?

Selecting the ideal Series W angle grinder for your facility starts with understanding the specific processing requirements of your operation. BAK Food Equipment offers a comprehensive range of models within the Series W line, each with distinct hopper capacities (from 110 to 1200 liters) and throat diameters (ranging from 5.1 to 11 inches). Facilities processing smaller batches or requiring frequent product changeovers may benefit from compact models like the W 130 A, while high-volume operations will find value in larger models such as the W 280 AL or W 200 E. Additionally, the choice between models designed for fresh products and those capable of handling frozen blocks (such as the B-Series) is crucial. For facilities that process both fresh and frozen materials, models like the W 200 B or W 280 B offer the flexibility to grind frozen blocks at temperatures as low as -7°F, streamlining production and reducing the need for pre-thawing.

Which factors influence grinder selection (capacity, frozen block capability, automation)?

Key factors influencing grinder selection include required throughput, the type of raw materials (fresh or frozen), and the desired level of automation. Hopper size and throat diameter directly impact the volume of product that can be processed per cycle, making them essential considerations for facilities with high production demands. The ability to grind frozen blocks is particularly valuable for operations looking to minimize handling and maintain product integrity. Automation features, such as programmable control panels and optional loading systems, further enhance efficiency by reducing manual labor and ensuring consistent results. Integration with other equipment—like injectors, mixers, or bone/tendon separators—can also be a deciding factor, as seamless connectivity supports a fully automated grinding system and optimizes workflow across the meat grinding line.

What ROI can companies expect from upgrading grinders?

Investing in a modern industrial meat grinder from BAK Food Equipment delivers significant long-term value. Upgraded grinders reduce labor costs through automation, improve operator safety with advanced controls and ergonomic design, and ensure consistent product quality by minimizing manual intervention. Enhanced grinding efficiency leads to lower product waste and higher yields, directly impacting profitability. The robust, stainless steel construction of BAK’s grinders ensures durability and longevity, reducing maintenance costs and downtime. For many facilities, the return on investment is realized through increased throughput, reduced operational expenses, and the ability to meet higher food safety and quality standards.

For tailored guidance on selecting the right grinder for your facility, BAK Food Equipment’s team is available to provide expert recommendations based on your unique production needs. Contact us to discuss your requirements and discover the optimal solution for your operation.

BAK Food Equipment Advantage

Why choose BAK grinders over competitors?

BAK Food Equipment stands out in the industrial grinder solutions market due to its decades of expertise in designing and supplying high-performance food processing equipment. Our angle grinders are engineered for reliability and efficiency, featuring robust stainless steel construction and advanced technology that ensures long-lasting performance in demanding environments. The unique angled auger system, with both feeding and pressing/grinder augers, delivers efficient and consistent grinding results, while the use of high-quality cutting tools and adjustable feeding speeds allows for precise customization to meet diverse processing needs. BAK grinders are also capable of handling both fresh and frozen products, making them versatile for a wide range of applications, including meat, poultry, seafood, pet food, and plant-based products. Our commitment to quality and innovation ensures that our customers receive commercial grinding technology that is both durable and adaptable to evolving industry requirements.

How does BAK support long-term success in food production?

At BAK Food Equipment, we recognize that long-term success in food production requires more than just reliable equipment—it demands a partnership built on comprehensive support and tailored solutions. We offer full-service support that includes expert installation, routine maintenance, and ongoing consultation to optimize your production line. Our grinders are available with customizable options such as bone/tendon separators and flexible loading systems, ensuring seamless integration into regional or global facilities. This adaptability allows us to address the unique challenges of each customer, whether they operate a local meat grinding line or a large-scale automated production facility. Our proven track record in delivering results across multiple food sectors demonstrates our ability to help clients achieve consistent product quality, operational efficiency, and regulatory compliance. By choosing BAK, you gain a trusted partner dedicated to supporting your growth and success in the competitive food processing industry.

To learn more about our grinder equipment and how it can benefit your operation, visit our grinder equipment page.