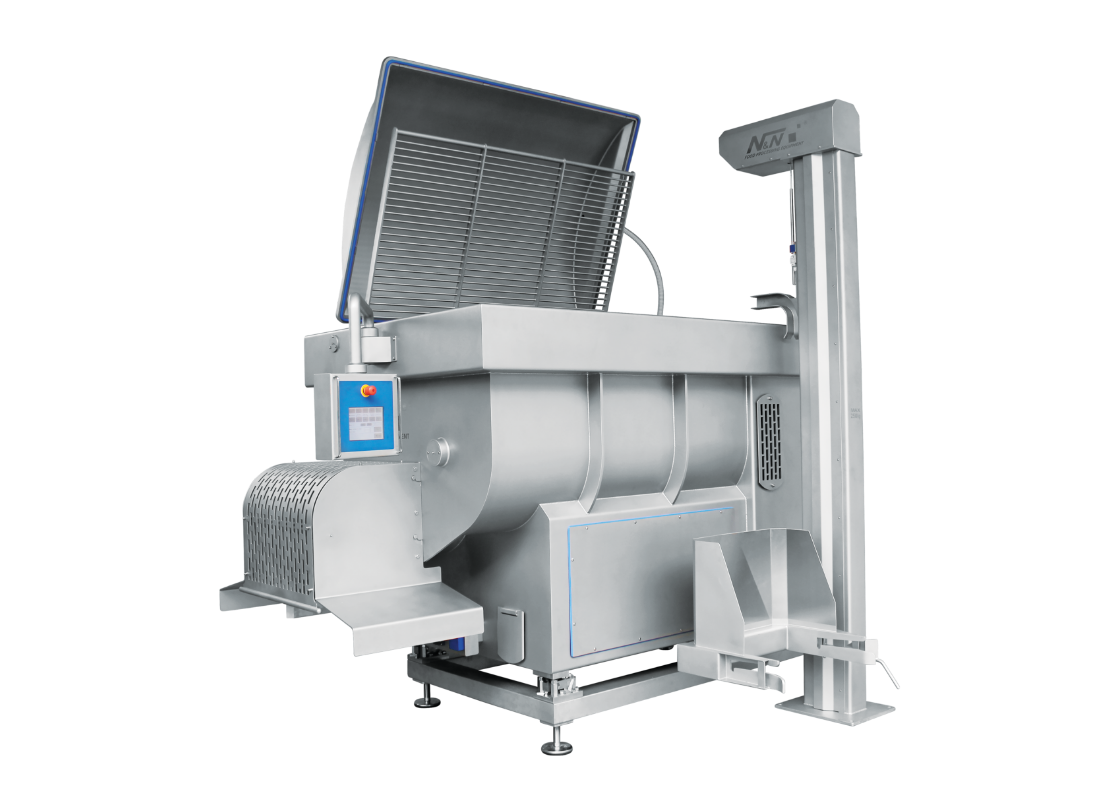

Series BW

Continuous Buggy Washers for Food Processing Facilities

Efficiency

Up to 80

buggies per hour

- High Efficiency Cleaning: Capable of thoroughly cleaning 40 to 80 standard buggies (400 Lbs/200 L) depending on model.

- Automatic Loading and Unloading: Reduces manual labor, enhances operator safety, and improves hygiene.

- Precise Variable Control: Easily adjust variable washing parameters such as water temperature, chemical concentration and intensity of rinsing.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs by adjusting variables such as water temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

NOMA continuous buggy washers are specifically designed to clean and sanitize buggies/Vemag Carts used for transporting ingredients or products in meat processing plants, bakeries, and other food production facilities. By ensuring thorough washing and rinsing, the buggy washers help prevent cross-contamination and maintain compliance with food safety regulations.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Continuous Buggy Washers for High-Volume Sanitation Workflows

What is a continuous buggy washer?

A continuous buggy washer is an automated washing system specifically engineered to clean and sanitize buggies (Vemag carts) used in food processing environments. These machines are designed to handle high volumes, with models capable of thoroughly cleaning between 40 and 80 standard buggies (400 lbs / 200 L) per hour. The system features automatic loading and unloading, reducing manual labor and enhancing operator safety. With precise variable controls, operators can easily adjust washing parameters such as water temperature, chemical concentration, and rinsing intensity to ensure optimal cleaning results. Built entirely from stainless steel, these washers are durable and suitable for demanding industrial settings.

What types of facilities benefit from continuous buggy washing?

Continuous buggy washers are ideal for facilities that require frequent and thorough cleaning of transport carts, such as meat processing plants, bakeries, and prepared-food production facilities. These industries rely on buggies and Vemag carts to move ingredients and products throughout the production process. By integrating a continuous buggy washer, these facilities can maintain high standards of hygiene, prevent cross-contamination, and support food safety compliance. The automation and efficiency of these systems make them particularly valuable in operations where high throughput and consistent sanitation are critical.

How does a continuous system improve sanitation and throughput?

The automation provided by continuous buggy washers significantly improves both sanitation and operational throughput. By automating the cleaning process, these systems deliver consistent and repeatable results, reducing the risk of human error and ensuring compliance with HACCP and other food safety standards. The ability to process up to 80 buggies per hour means that production lines can maintain a steady flow without bottlenecks caused by manual cleaning. Additionally, features such as programmable control panels and easy maintenance further enhance efficiency, while reducing labor fatigue and supporting overall sanitation automation. This makes continuous buggy washers an essential component of modern food processing operations focused on hygiene, productivity, and regulatory compliance.

How the Continuous Washing Cycle Operates

What are the key steps in the wash cycle?

A continuous buggy washer operates through a carefully sequenced wash cycle designed for maximum efficiency and hygiene. The process begins with automatic loading, where buggies or Vemag carts are placed onto the conveyor system, minimizing manual handling and improving operator safety. The buggies then move through a wash sequence followed by a rinse stage to remove residual cleaning agents and contaminants. Finally, the buggies are automatically unloaded, ready for immediate reuse. This step-by-step workflow ensures consistent sanitation and supports compliance with food safety standards.

How do the wash and rinse stages function in a continuous system?

In a continuous system, the washing stage uses high power jets and chemical dosing to dislodge any debris in the buggy and sanitize it. This is followed by a rinsing cycle to ensure that any residual cleaning agents and contaminants are removed. At the end of the process, the buggy is fully cleaned and sanitized, ready for immediate reuse. This seamless transition between stages is key to sanitation workflow optimization, reducing downtime and manual intervention.

How do adjustable parameters affect cleaning results?

Continuous buggy washers from BAK Food Equipment feature advanced programmable control panels, allowing operators to adjust critical parameters such as wash temperature, chemical concentration, and rinsing intensity. These variable controls are essential for tailoring the cleaning process to different levels of soiling and specific regulatory requirements. For example, higher wash temperatures and increased chemical dosing can be used for heavy residues or allergen reduction, while rinse intensity can be adjusted to ensure complete removal of cleaning agents. The ability to fine-tune these settings not only improves residue removal and allergen control but also helps maintain compliance with stringent food safety regulations. This flexibility ensures that every wash cycle delivers optimal results, regardless of the production demands.

Where Continuous Buggy Washers Are Used

What industries rely on buggies/carts?

Continuous buggy washers are essential in a range of food processing industries where buggies (Vemag carts) are used to move ingredients and products. Key sectors include meat processing, poultry, bakery, prepared foods, ingredients, spices, and pet food manufacturing. In these environments, buggies are in constant use for transferring raw materials, finished goods, or byproducts between different stages of production. The high frequency of use and direct contact with food products make effective cleaning and sanitation of these carts critical for maintaining product quality and safety.

How does the washer support cross-contamination prevention?

Continuous buggy washers are engineered to deliver thorough cleaning and sanitization, which is vital for preventing cross-contamination and managing allergens. By using precise variable controls for water temperature, chemical concentration, and rinse intensity, these washers ensure that every buggy is consistently cleaned to a high standard. This consistency is crucial for allergen management and for avoiding the risk of cross-contact between different product batches. Automated unloading further reduce manual handling, minimizing the potential for human error and contamination.

What regulatory standards do these systems support?

These washing systems are designed to help facilities comply with stringent food safety and sanitation regulations, including USDA sanitation requirements, FDA guidelines, HACCP protocols, and GFSI standards. By providing reliable, repeatable cleaning results, continuous buggy washers support a facility’s ability to meet regulatory audits and maintain certifications. Their robust stainless steel construction and easy-to-clean design also align with hygienic design standards required in regulated food processing environments.

How do these washers fit into upstream or downstream processes?

Continuous buggy washers are often integrated into automated production workflows, supporting upstream and downstream equipment such as conveyors, tumblers, grinders, and mixing lines. Their high throughput—capable of cleaning up to 80 buggies per hour—ensures that clean carts are always available, supporting uninterrupted production and reducing bottlenecks. This integration is especially valuable in continuous production environments where predictable output and operational efficiency are priorities.

What facilities typically integrate them into automated operations?

Facilities that prioritize high-volume, continuous production—such as large-scale meat processing plants, industrial bakeries, and prepared food manufacturers—are most likely to integrate continuous buggy washers into their automated operations. These facilities benefit from the washer’s ability to deliver consistent, high-quality cleaning results while supporting compliance with food safety regulations and minimizing labor requirements. By automating the cleaning process, these operations can maintain high standards of meat-processing hygiene and allergen management without sacrificing productivity.

Maintenance, Durability, and Operating Efficiency

What makes the system easy to maintain?

BAK Food Equipment’s continuous buggy washers are engineered with easy-access panels and a sanitary design, making routine cleaning and maintenance straightforward and efficient. The stainless steel construction not only ensures long-lasting durability but also simplifies the cleaning process, as surfaces are smooth and resistant to residue buildup. The intuitive touch screen control panel allows operators to quickly access maintenance settings and monitor system performance, further reducing downtime and labor requirements.

How do filtration and recycling features reduce costs?

The inclusion of rotary filters and water recycling systems in BAK’s industrial buggy washing systems significantly lowers both water and chemical consumption. Rotary filters continuously remove debris from the wash water, extending the life of cleaning solutions and reducing the frequency of water changes. Water reuse systems capture, filter, and recycle rinse water, minimizing overall water usage and associated utility costs. These features not only contribute to sustainability goals but also deliver measurable savings on operating expenses, making the washers a cost-effective solution for food processing facilities.

What preventive maintenance practices improve uptime?

To optimize uptime and ensure reliable operation, BAK recommends a set of routine preventive maintenance practices to be performed by BAK’s technicians or experienced operators. Periodically checking and cleaning spray nozzles prevents blockages and maintains consistent cleaning performance. Inspecting pumps and rotary filters ensures that all components are functioning efficiently and helps identify potential issues before they lead to unplanned downtime. Scheduled filter cleaning and prompt attention to any system alerts from the advanced control panel further support uptime optimization. By following these guidelines, facilities can maximize the lifespan of their low-maintenance sanitation equipment and reduce the risk of costly interruptions.

Emphasizing durability and thoughtful design, BAK Food Equipment’s continuous buggy washers deliver long-term value by lowering maintenance demands, reducing resource consumption, and supporting consistent, efficient operation in demanding food processing environments.

Why Food Processors Choose BAK Continuous Washing Systems

What expertise sets BAK apart?

BAK Food Equipment specializes in sanitary industrial equipment, with a focus on providing advanced solutions for food processors who require the highest standards of cleanliness and efficiency. Our partnership with NOMA brings decades of industrial sanitation expertise to the U.S. market, offering continuous buggy washers engineered specifically for the rigorous demands of food production environments. These systems are designed to thoroughly clean and sanitize buggies and Vemag carts, helping facilities maintain compliance with food safety regulations and prevent cross-contamination. BAK’s proven track record with USDA-regulated facilities demonstrates our commitment to meeting the strictest hygienic design standards in the industry.

Why is U.S.-based support valuable?

Choosing BAK means gaining access to responsive, U.S.-based support for installation, parts, and ongoing food equipment service. Our team is headquartered in Burr Ridge, Illinois, ensuring that customers receive timely assistance and expert guidance throughout the lifecycle of their equipment. This local presence is especially valuable for minimizing downtime and ensuring that your washing systems continue to operate at peak performance. Whether you need technical support, replacement parts, or routine maintenance, BAK’s dedicated service team is ready to help.

What makes these washers reliable in demanding environments?

BAK continuous buggy washers are built entirely from stainless steel, ensuring exceptional durability and long-lasting performance even in the most demanding food processing environments. The robust construction is complemented by advanced features such as automatic loading and unloading, precise variable control of washing parameters, and intuitive programmable control panels. These design elements not only enhance operator safety and hygiene but also make routine cleaning and maintenance straightforward. With the capacity to clean up to 80 buggies per hour, BAK’s washers are engineered for heavy-duty, high-volume operations, making them a reliable choice for food processors who prioritize efficiency and sanitation.

Continuous Buggy Washer FAQs

What is a continuous buggy washer?

A continuous buggy washer is an industrial washing system designed to automatically clean and sanitize buggies (also known as Vemag carts) used for transporting ingredients or products in food processing environments. These washers use a washing tunnel to provide thorough cleaning and rinsing, helping facilities maintain high hygiene standards and prevent cross-contamination.

What is the throughput of a continuous buggy washer?

Throughput depends on the model and configuration. BAK Food Equipment offers continuous buggy washers capable of cleaning between 40 and 80 standard buggies (400 lbs/200 L) per hour. This high efficiency makes them ideal for facilities with demanding sanitation requirements and high production volumes.

Which industries benefit from using a continuous buggy washer?

Continuous buggy washers are commonly used in meat processing plants, bakeries, prepared foods, spice manufacturing, and pet food production. These industries rely on automated washing systems to maintain sanitation, comply with food safety regulations, and reduce the risk of cross-contamination.

Does the washer reduce labor requirements?

Automatic loading and unloading features significantly reduce manual handling, which not only improves operator safety but also enhances labor efficiency. By automating the cleaning process, facilities can reallocate labor to other critical tasks and reduce the risk of workplace injuries.

What optional modules are available?

Optional modules for continuous buggy washers include SCADA monitoring systems for real-time performance tracking, rotary filtration systems to extend water life and improve cleaning efficiency, and customized conveyors for seamless integration into automated production lines.

How much water does the washer use?

Water usage varies by model and configuration, but integrated filtration and recycling modules help minimize consumption and reduce operating costs. These features support sustainability initiatives and help facilities manage utility expenses.

Is the system easy to maintain?

Continuous buggy washers from BAK Food Equipment are constructed entirely from stainless steel for durability and easy cleaning. Thoughtfully designed access panels and hygienic design standards make routine maintenance straightforward, ensuring long-term reliability and compliance with sanitation protocols.

For more information or to discuss your facility’s specific needs, please contact BAK Food Equipment.