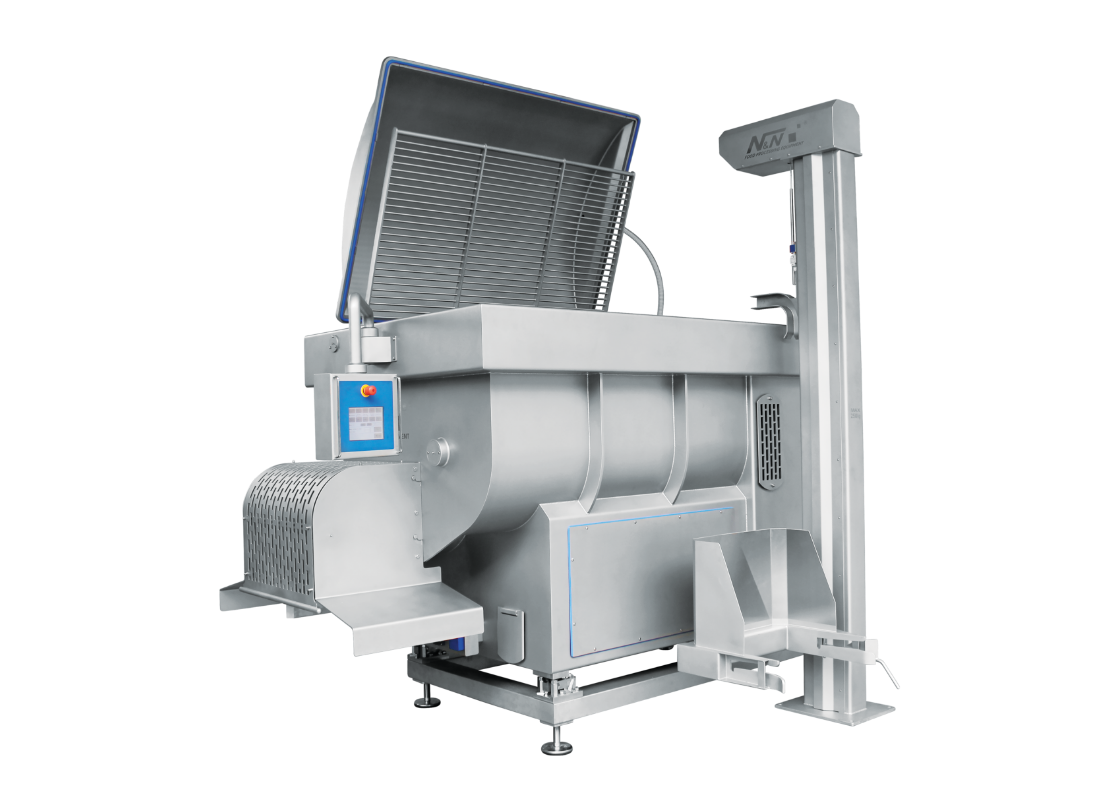

Series FL

Flakers

Throughput

3300 - 17,500

lbs Per Hour

- Optimized Cutting Performance: Operators achieve superior cutting results thanks to the unique design of the knives and drum geometry. Paired with an integrated pneumatic clamping system, this ensures efficient processing of blocks while maintaining low noise operation for improved user comfort.

- Versatile Blade Thickness: Can be equipped with two types of blades, offering six different cutting thicknesses: 3, 6, and 9 mm with low knives, and 14, 17, and 20 mm with high knives. This versatility allows for optimal adaptation to your production requirements.

- Precision Cross-Cutting System: “Cross” blades work with the main U-shaped blades to flake the product and cut it crosswise, creating smaller pieces. This is ideal for further processing in mixes, preparing emulsions for sausage production, or ground meat for hamburgers and other molded products.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

The N&N Nadratowski flakers are ideal for cutting blocks of frozen meat, fish, vegetables, fruit, dairy products like cheese, and confectionery items such as chocolate blocks.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team