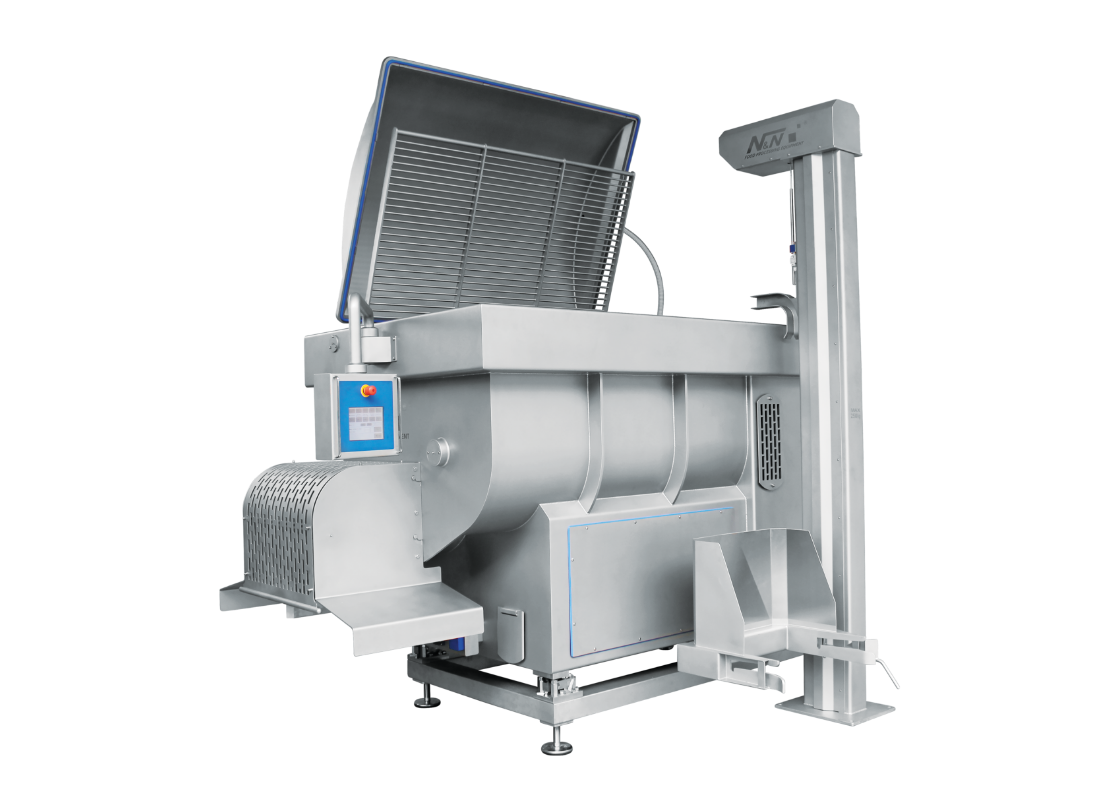

Industrial Batch Smokehouses

*Our smoke chambers offer flexibility in size, smoke type, and layout, allowing you to tailor the system to meet the specific needs of your production.

- Durable, Fully Welded Chamber: The fully welded chamber provides a significant advantage in the smoking process by ensuring no leakage over time. This design maximizes durability and enhances the overall smoking performance.

- Flexible Air Handling System: Smokehouses can be designed with either an alternating flap system or a dual fan system which continuously changes the air circulation around the products in the chamber, ensuring an even smoking process.

- Hot, Cold, or Hot/Cold Smoke Capabilities: Can be equipped to handle hot smoke, cold smoke, or both, making it suitable for a wide range of smoked products, from bacon to smoked salmon.

- Remote Monitoring and Control: Through a VPN connection, service technicians can remotely access the system's microprocessor, reducing the need for costly on-site service visits and ensuring optimal performance.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs.

Easy Cleaning and Maintenance:

Thoughtfully designed with an integrated CIP system to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Single Row

Double Row

Applications

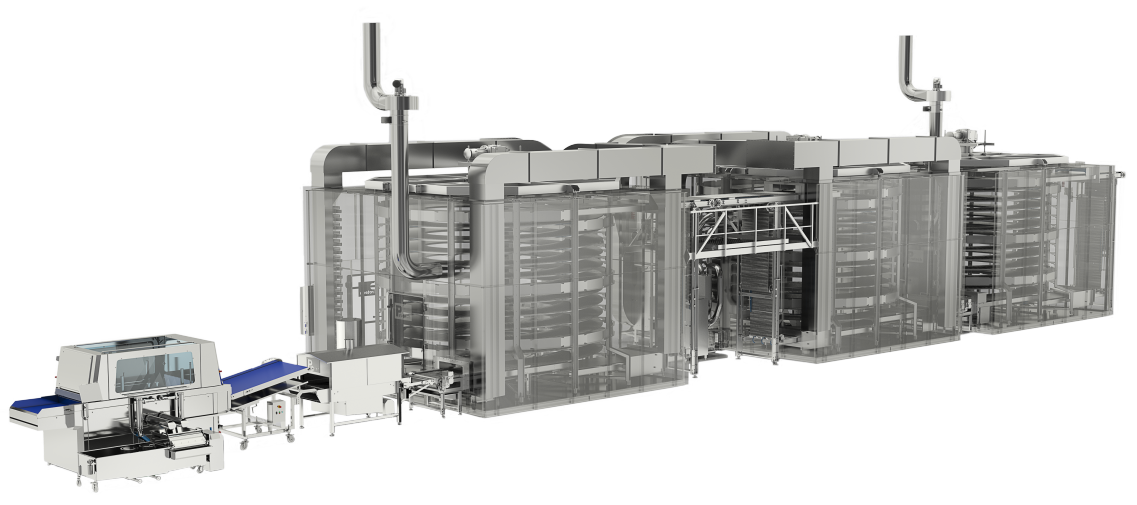

Protech Smoking Chambers are designed for a wide range of food processing applications, including meats, poultry, seafood, and more. Ideal for both hot and cold smoking, these chambers ensure consistent flavor, color, and texture across all products. Our chambers offer precise control over temperature, smoke levels, and humidity to deliver premium results at high production volumes.

Large Bacon Producer

"Before we introduced BAK’s automated spiral system, our bacon production rose and fell with Monday’s workforce. Now that we’ve streamlined the entire process—smoking, cooking, and chilling in a single continuous system—we’ve not only stabilized our output, but we’re producing better bacon than ever. It’s been a complete game-changer.“ – Leadership team

You Might Also Like

About Batch Smokehouses

What is a batch smokehouse?

A batch smokehouse is a controlled food smoking chamber specifically designed for curing and flavoring a variety of products such as meats, poultry, seafood, cheeses and more. Batch smokehouses are engineered to deliver consistent results through advanced technology. BAK Food Equipment’s batch smokehouses are built with fully welded, stainless steel chambers to ensure durability and prevent leakage, which is critical for maintaining optimal smoking conditions over time.

How is it used in food and meat processing?

In food and meat processing, batch smokehouses play a vital role in imparting flavor, color, and texture to products. These industrial smokehouses are equipped to handle hot smoking, cold smoking, or a combination of both, making them suitable for a wide range of applications—from smoked sausage and bacon to seafood like smoked salmon. The flexible air handling system, which can be configured with either an alternating flap or dual fan system, ensures even air and smoke distribution throughout the chamber. This results in uniform product quality, regardless of batch size. Operators can precisely control temperature, humidity, and smoke levels using an advanced programmable control panel, allowing for the creation and storage of custom programs tailored to specific recipes or production requirements.

What advantages does BAK’s smokehouse offer over alternatives?

Batch smokehouses from BAK Food Equipment offer several advantages over other smokehouses in the market. First, their industrial-grade construction and fully welded design provide superior durability and prevent smoke or heat loss, which enhances both efficiency and product consistency. The ability for technicians to remotely monitor and control the system via VPN connection reduces downtime and costly on-site service visits, ensuring optimal performance with minimal disruption. Additionally, the flexible design allows for customization in size, smoke type, and layout, accommodating a variety of production scales and product types. Our batch smokehouses are thoughtfully designed with an integrated CIP (Clean-in-place) system to make cleaning and maintenance straightforward and efficient. Overall, these modern batch smokehouses deliver greater precision, consistency, and flexibility, making them an essential component of advanced meat processing equipment.

Why Choose BAK Food Equipment

Why should processors choose BAK’s smokehouses?

BAK Food Equipment’s smokehouses are engineered to deliver exceptional performance, flexibility, and reliability for processors of all sizes. With deep expertise in automated food smoking and large-scale meat processing equipment, BAK offers smokehouses that are built to meet the rigorous demands of modern food production. Our smokehouses feature fully welded, stainless steel chambers that ensure long-term durability and prevent leakage, maximizing both hygiene and operational efficiency. These smokehouses are designed for versatility, accommodating a wide range of products—from sausage and bacon to seafood—by offering hot, cold, or combined smoking capabilities. Advanced programmable control panels allow operators to precisely manage temperature, smoke levels, and humidity, ensuring consistent product quality and flavor. Additionally, remote monitoring and control via VPN enable BAK’s service technicians to provide rapid support and minimize downtime, making our smokehouses a smart investment for processors seeking both performance and peace of mind.

What sets BAK apart from other industrial smoking system suppliers?

BAK Food Equipment distinguishes itself through a combination of technical expertise, robust engineering, and comprehensive customer support. Unlike many suppliers, BAK provides in-house engineering, installation, and remote system access via VPN, ensuring seamless integration of their industrial smoking solutions into any production environment. Our batch smokehouses are thoughtfully designed with an integrated CIP (Clean-in-place) system to make cleaning and maintenance straightforward and efficient. BAK’s flexible air handling systems—offering either alternating flap or dual fan configurations—ensure even smoke distribution and uniform product results, whether in small batch or continuous-flow production. With a proven track record supporting processors from small operations to large-scale facilities, BAK’s commitment to quality, innovation, and customer service sets them apart as a trusted partner in the food processing industry.

Smokehouse FAQs

What is a batch smokehouse used for?

A batch smokehouse is designed to smoke and cure meats, poultry, and seafood in a controlled environment. By precisely managing temperature, humidity, and smoke levels, these chambers ensure uniform results across every batch. This makes them ideal for producing consistent flavor, color, and texture in products such as sausage, bacon, ham, and smoked fish.

What’s the difference between hot and cold smoking?

Hot smoking involves both cooking and flavoring the product at higher temperatures. This process is suitable for items like sausage and poultry, where both a cooked texture and smoky flavor are desired. Cold smoking, on the other hand, imparts smoke flavor at lower temperatures (generally below 90°F) without cooking the product, making it ideal for delicacies like smoked salmon or certain cured meats.

Can one chamber handle both hot and cold smoking?

Yes, BAK’s batch smokehouses are engineered for versatility. They can be configured to handle hot smoking, cold smoking, or a combination of both within the same unit. This flexibility allows processors to switch between different smoking methods as production needs change, all within a single, durable chamber.

How does air circulation affect smoking quality?

Consistent air circulation is critical for even smoking. BAK smokehouses use either an alternating flap system or a dual-fan air handling system to continuously move smoke and air throughout the chamber. This allows BAK smokehouses to impart high quality flavor and color onto a wide range of products.

How does remote monitoring improve performance?

Remote monitoring, enabled by a secure VPN connection, allows technicians to access the smokehouse’s microprocessor from off-site locations. This capability streamlines troubleshooting, system optimization, and program adjustments, reducing the need for on-site service visits and minimizing downtime.

What products are most commonly smoked in batch smokehouses?

Batch smokehouses are widely used for smoking bacon, sausage, poultry, ham, seafood, and other protein products. The controlled environment and programmable settings make them suitable for a broad range of applications, ensuring premium results at both small and large production volumes.

For more information on our full range of solutions, visit our Food Equipment & Industrial Food Processors Solutions page.