Series MIX COOK

Parallel Twin Shaft Cooking Mixers (Paddle or Ribbon)

Bowl Volume

500-4800

Liters

Max Mixing Capacity

825-8000

Lbs

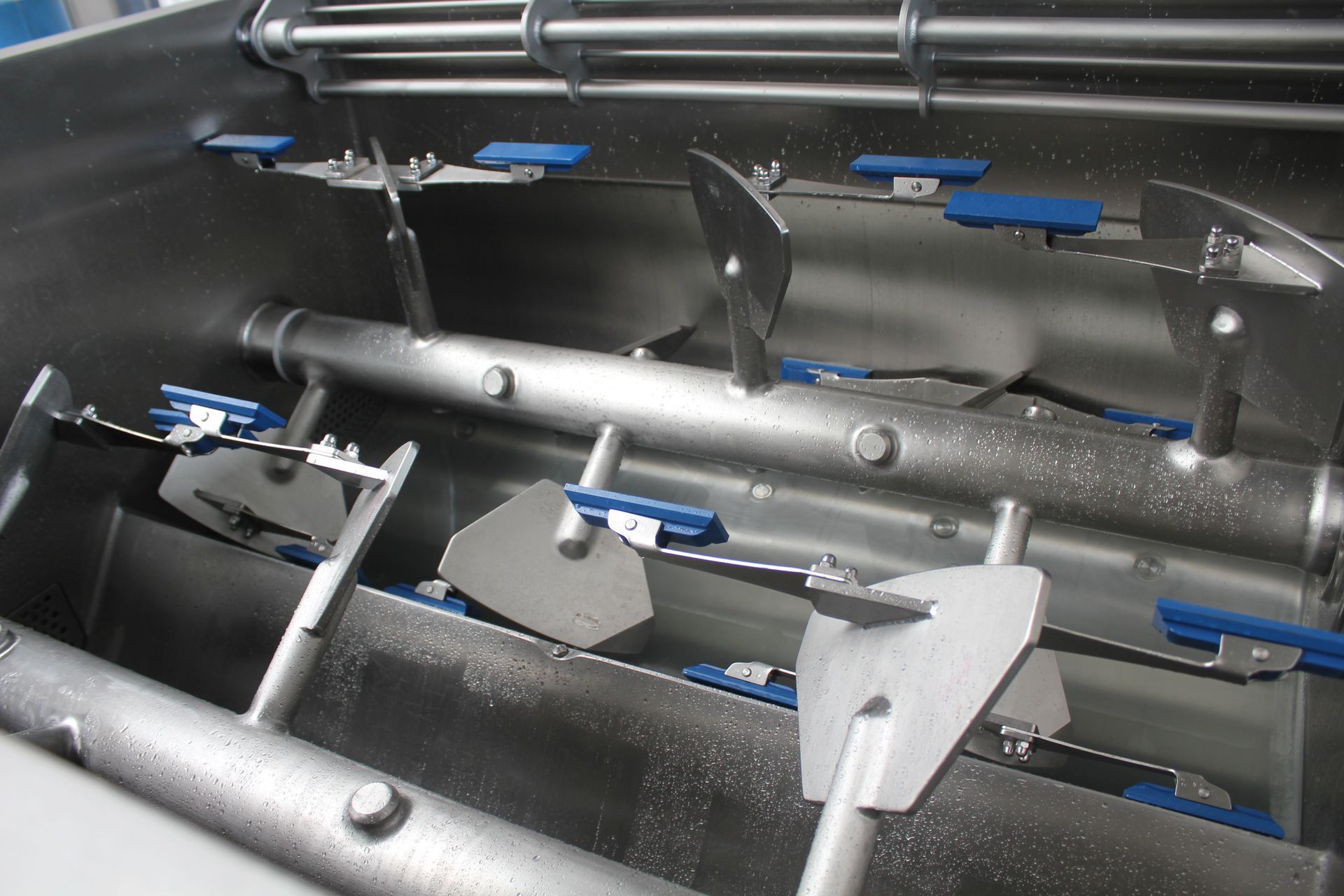

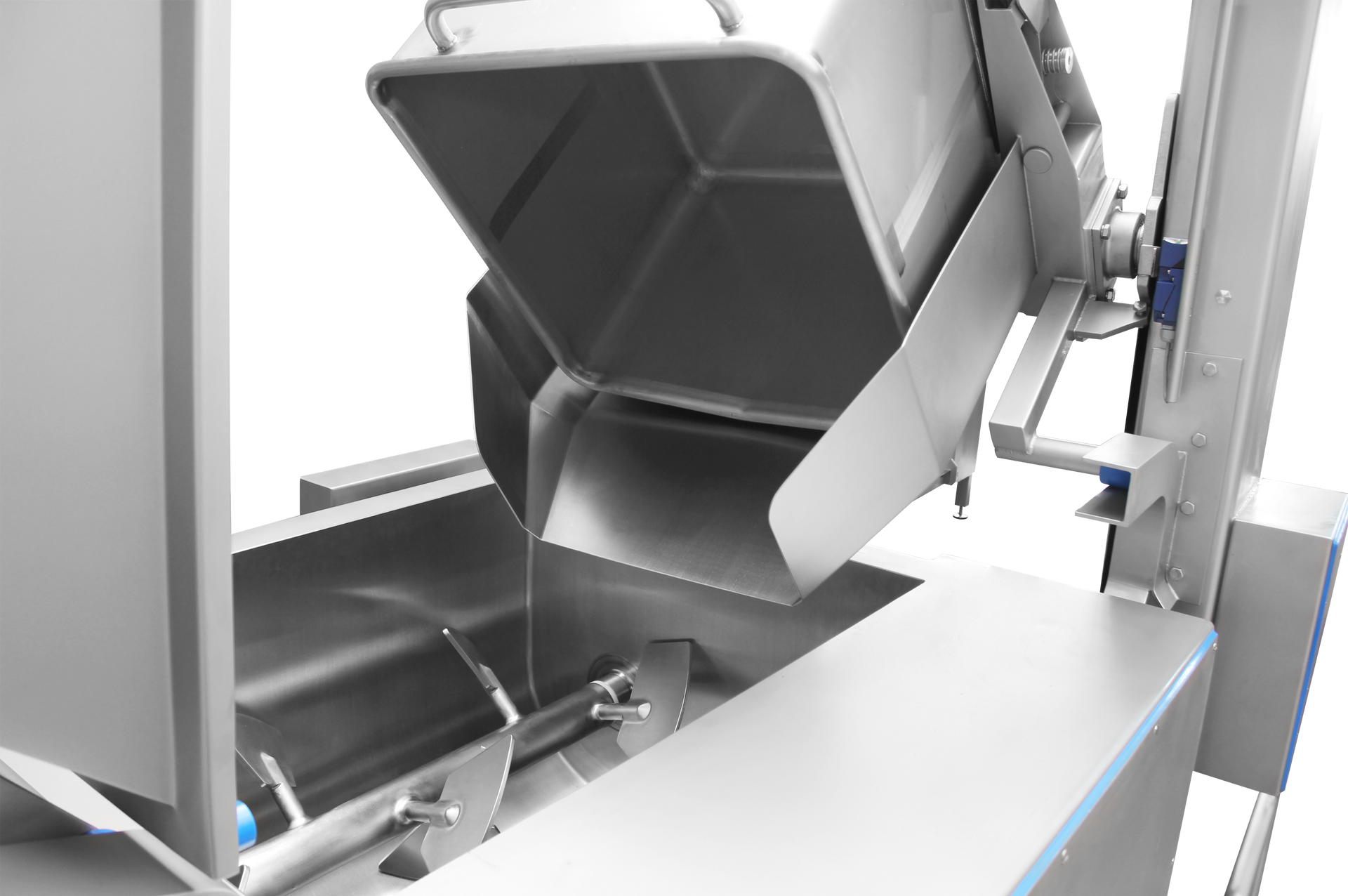

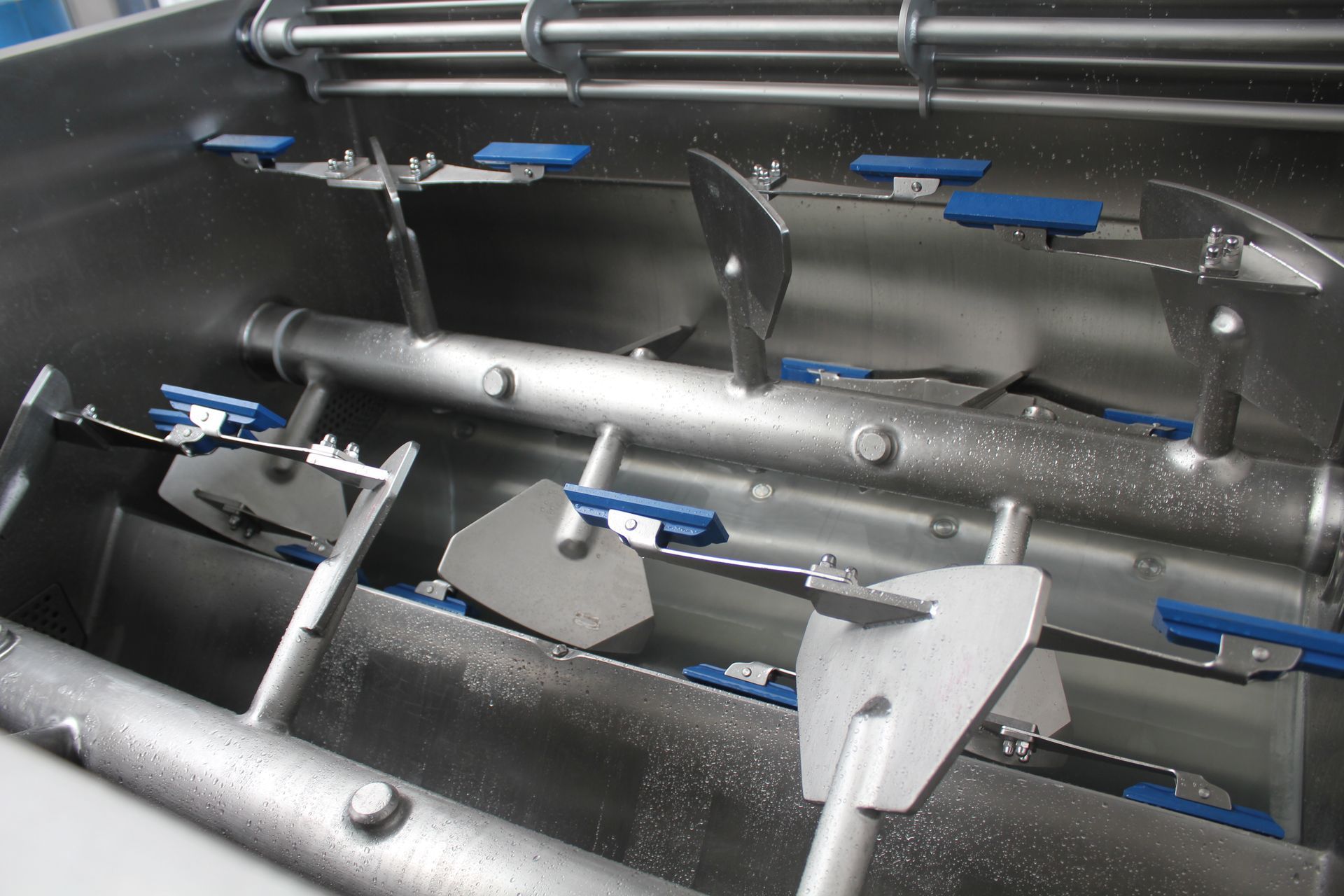

- Dual Parallel Paddle or Ribbon Shafts with Heating Jacket: Features dual parallel paddle or ribbon shafts at the same height, allowing independent adjustment of speed and rotation direction for each shaft. It is fitted with a steam or oil heating jacket as standard, to enable quick, even mixing and cooking of various products.

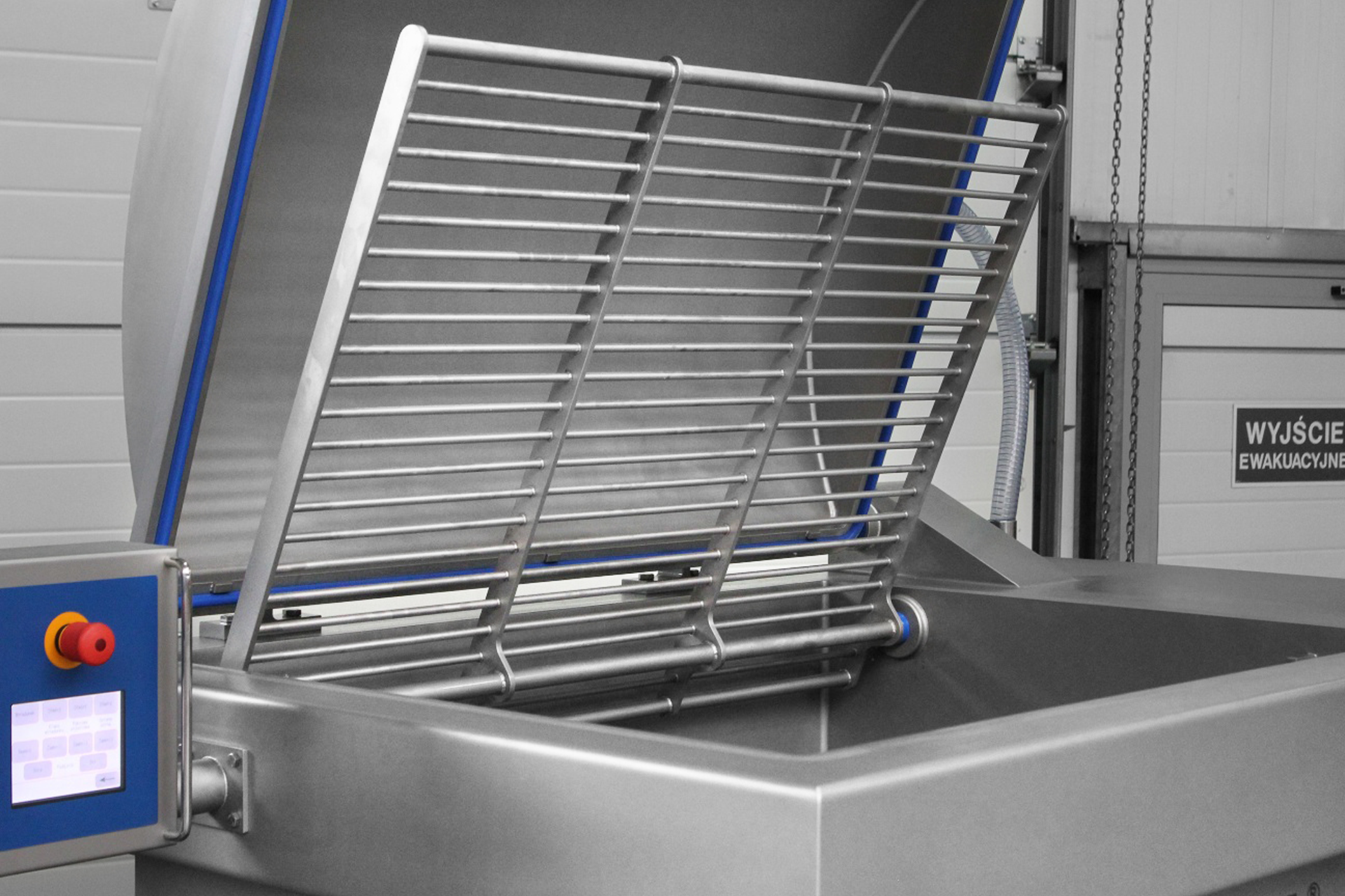

- Vacuum Option: Equipped with a reinforced bowl and airtight top cover, allowing up to 99% vacuum, which enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming.

- Variable speed: Offers precise speed adjustments, allowing the shafts to rotate at any desired speed within the machine's range.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

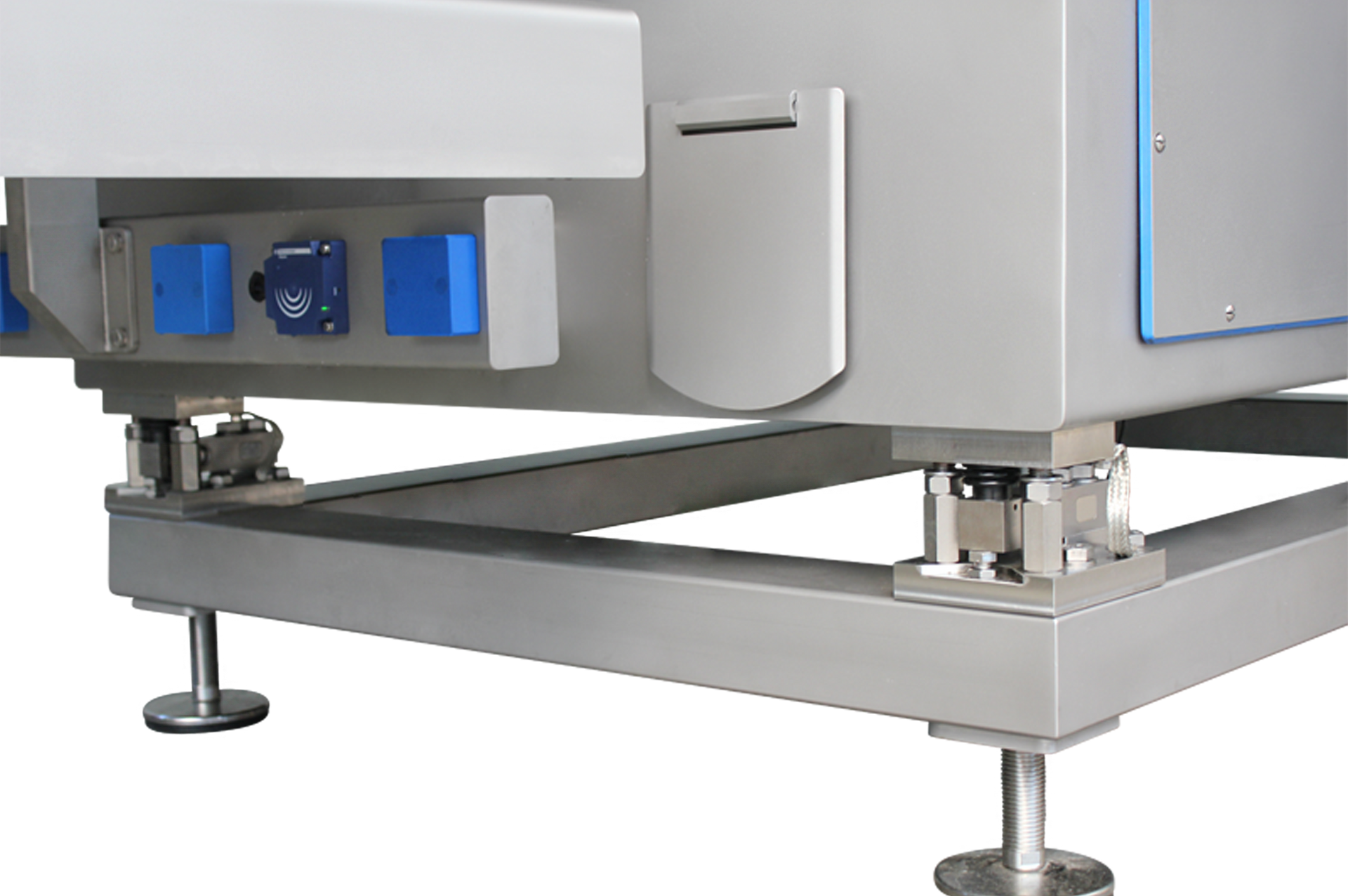

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as shaft rotation speed, shaft rotation direction, and vacuum level.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient

Technical Information

Applications

The MIX Cook series mixers are versatile and designed for mixing and cooking a wide range of products, including sauces, purées, baby food, vegetables, rice, grains, minced meat, and offal.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Parallel Twin Shaft Cooking Mixers

What is the Series MIX COOK mixer and what sets it apart?

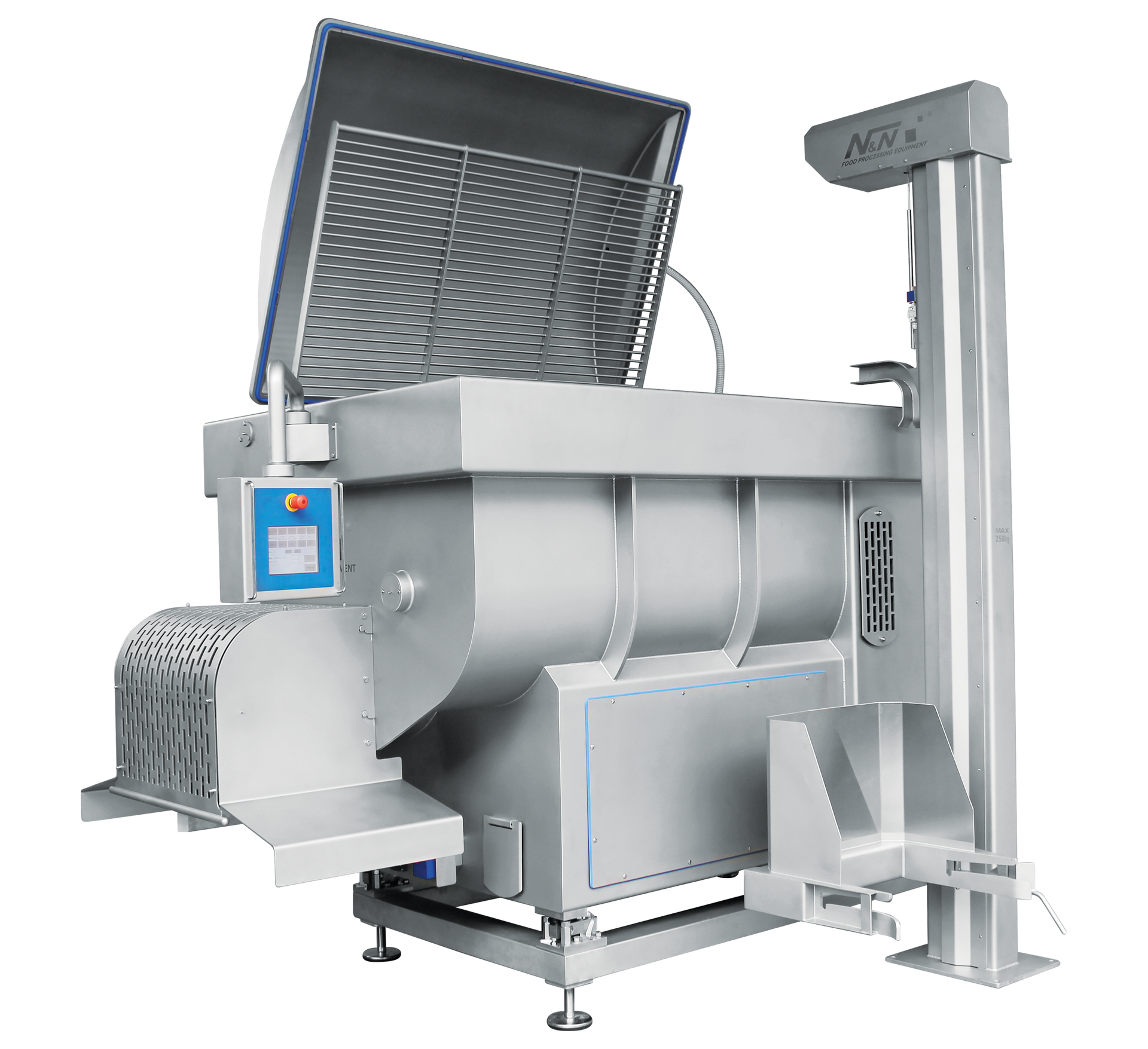

The Series MIX COOK mixer from BAK Food Equipment is a high-capacity, industrial-grade solution designed for both mixing and cooking in a single, streamlined process. These parallel twin shaft mixers are available with either paddle or ribbon shafts, both positioned at the same height for optimal blending performance. What distinguishes the MIX COOK series is its integration of a steam or oil heating jacket, which enables rapid and uniform cooking while ingredients are being mixed. This dual-functionality not only saves time but also ensures consistent product quality across a wide range of food applications. The robust stainless steel construction and advanced programmable control panel further set the MIX COOK apart, offering durability and precise control for demanding food manufacturing environments.

How does it combine cooking and mixing for food processing applications?

The MIX COOK series is engineered to handle both cooking and mixing simultaneously, making it an ideal choice for food processors seeking efficiency and versatility. The dual parallel paddle or ribbon shafts can be independently adjusted for speed and rotation direction, allowing for gentle yet thorough blending of ingredients with varying consistencies. The integrated heating jacket—powered by either steam or oil—ensures that heat is distributed evenly throughout the batch, resulting in rapid cooking without compromising ingredient integrity. For applications requiring enhanced absorption, flavor infusion, or density control, the optional vacuum system allows the mixer to achieve up to 99% vacuum, improving protein extraction, liquid absorption, and the distribution of spices and additives. This combination of features makes the MIX COOK a comprehensive cooking and mixing system suitable for products such as sauces, purées, baby food, vegetables, rice, grains, minced meat, and offal.

Why choose BAK’s N&N MIX COOK for large-scale production?

BAK’s N&N MIX COOK mixers are specifically designed to meet the rigorous demands of large-scale food production. With bowl volumes ranging from 500 to 4,800 liters and maximum mixing capacities up to 8,000 pounds, these mixers can accommodate high-throughput operations. The advanced programmable control panel allows operators to create and store up to 100 custom programs, adjusting variables such as shaft speed, rotation direction, and vacuum level for repeatable, high-quality results. The durable stainless steel construction ensures longevity and reliability, while thoughtful design features make cleaning and maintenance straightforward. As a trusted supplier of N&N food processing equipment across the U.S. and Canada, BAK Food Equipment delivers not only robust industrial food cookers but also the expertise and support needed to optimize your production line. The MIX COOK series is a proven choice for processors seeking efficient, high-capacity, and flexible vacuum cooking mixers for a wide range of food manufacturing needs.

Key Features and Advantages of MIX COOK Series

What technical features make the MIX COOK series unique?

The MIX COOK series from BAK Food Equipment stands out in the market due to its advanced engineering and versatility. At the core of its design are dual parallel shafts—available in either paddle or ribbon configurations—positioned at the same height. Each shaft operates independently, with variable speed and direction, giving operators precise control over product texture and mixing intensity. This flexibility is essential for achieving optimal results across a wide range of food products, from sauces and purées to minced meats and grains.

Other key features include a robust heating jacket, which is compatible with either steam or oil. For applications requiring enhanced product quality, the MIX COOK series offers an optional vacuum system that can achieve up to 99% vacuum.

The programmable control panel is another standout feature. Operators can store up to 100 custom recipes, adjusting parameters such as shaft speed, direction, vacuum level, and temperature.

Durability and ease of maintenance are also central to the MIX COOK series. Constructed entirely from stainless steel, these mixers are built for continuous industrial use and are designed for straightforward cleaning and maintenance. Pneumatic lid operation and hydraulic unloading further enhance safety and ergonomics, allowing for quick batch turnover and minimizing manual handling.

How do these mixers improve production efficiency and product consistency?

The MIX COOK series is engineered to streamline production processes and deliver consistent, high-quality results. The dual parallel shaft design—whether paddle or ribbon—ensures thorough mixing and even distribution of ingredients, which is critical for product consistency. Independent control of each shaft allows for tailored mixing actions, reducing the risk of over- or under-mixing and ensuring uniform texture throughout the batch.

The integrated heating jacket accelerates cooking times and guarantees even heat distribution, reducing the likelihood of hot spots or unevenly cooked product. When the optional vacuum system is utilized, it not only removes unwanted air but also enhances the absorption of flavors and additives, resulting in a more homogenous and flavorful end product.

The programmable control panel significantly boosts efficiency by allowing operators to quickly switch between recipes and production runs with minimal setup time. This automation reduces human error and ensures that each batch meets the same high standards, regardless of operator or shift.

Finally, features such as pneumatic lid opening and hydraulic unloading make operation safer and more ergonomic, while also speeding up batch turnover. The stainless-steel construction and thoughtful design for easy cleaning further minimize downtime between batches, maximizing overall production throughput.

By combining advanced mixing technology, precise process control, and robust construction, the MIX COOK series delivers significant improvements in both production efficiency and product consistency, making it an ideal choice for modern food manufacturing operations that demand reliability and flexibility in their vacuum cooking mixer and industrial sauce cooker applications.

Customization and Optional Features

What optional systems are available for the MIX COOK series?

The MIX COOK series from BAK Food Equipment is engineered for versatility, offering a range of optional systems to enhance performance and adapt to diverse production needs. Key optional features include:

Bowl Scraper System: This system prevents product scorching and ensures complete heat transfer by continuously scraping the bowl’s interior surface. It is especially valuable for products prone to sticking or burning, maintaining product quality and reducing waste.

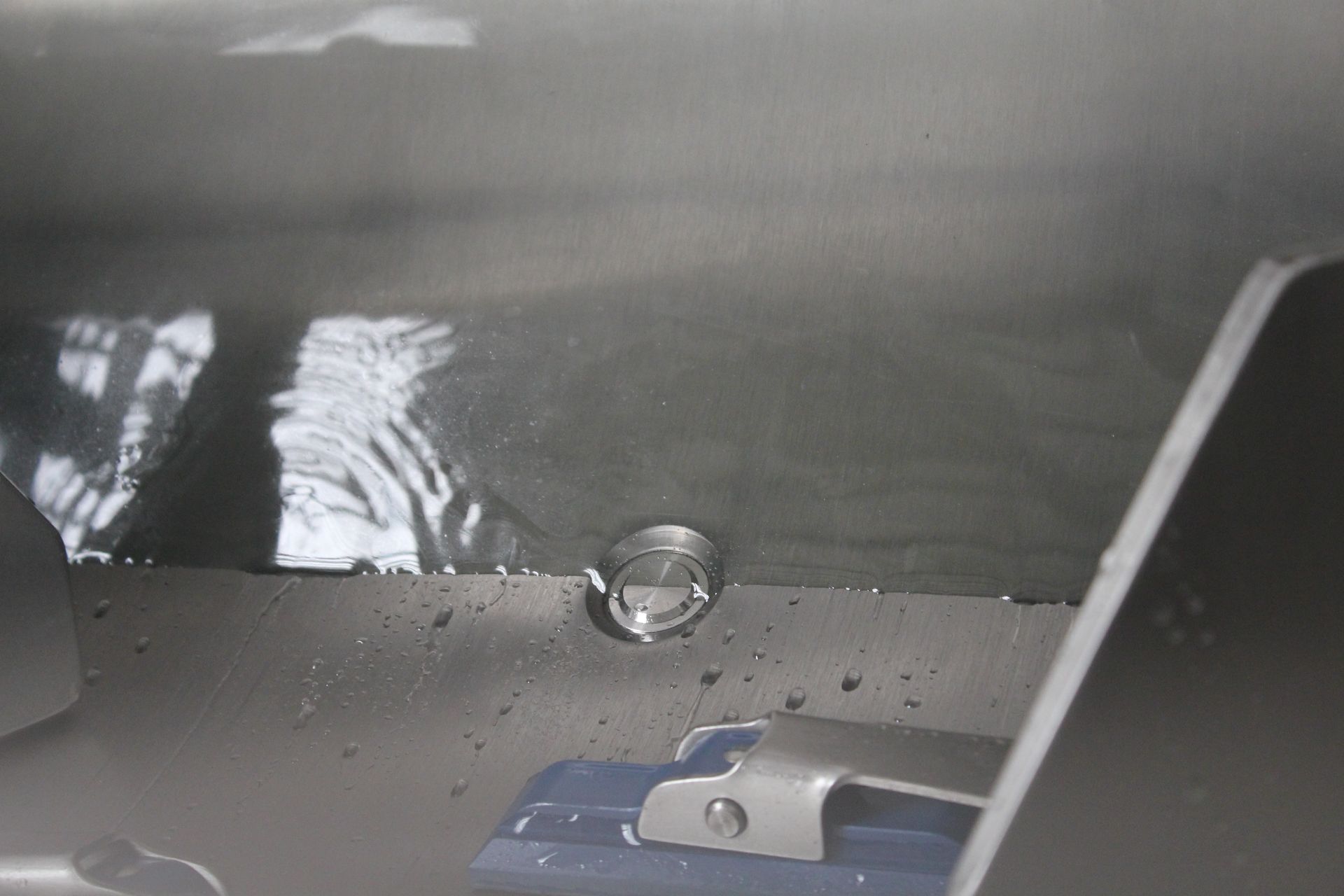

Direct Steam Injection: By injecting steam directly into the product, this system accelerates the cooking process while maintaining a uniform temperature throughout the batch.

Water Dosage System: The automated water dosage system allows for precise addition of liquids at set stages of the process. This ensures recipe accuracy and repeatability, which is critical for maintaining product consistency in automated food processing environments.

Load Cells: Integrated load cells track ingredient quantities in real time, enabling precise batch control and supporting full or partial automation of the mixing process.

Openwork Cover Option: The additional openwork cover allows operators to add spices or other ingredients during operation without interrupting the process.

Loading Systems: To facilitate seamless integration into various production workflows, loading systems are available in fixed, mobile, or free-standing configurations.

Partner with BAK for Complete Cooking and Mixing Solutions

Why partner with BAK for industrial cooking equipment?

BAK Food Equipment stands out as a trusted partner for food processors seeking advanced industrial cooking solutions. Our expertise lies in integrating N&N mixers into complex production lines, ensuring seamless compatibility with your existing or planned automation systems. Whether you require a parallel twin shaft cooking mixer, a vacuum cooking mixer, or a custom-configured paddle or ribbon cooking mixer, BAK delivers equipment that is engineered for efficiency, hygiene, and reliability. Our solutions are designed to meet the rigorous demands of large-scale food manufacturing, supporting a wide range of applications from sauces and purées to grains, minced meat, and baby food. Each system is built from industrial-grade stainless steel, offering exceptional durability and easy cleaning to maintain the highest standards of food safety.

How does BAK support food processors from setup to production?

From the initial consultation to full-scale production, BAK Food Equipment provides comprehensive support at every stage. Our team works closely with you to understand your production goals and recommend the right industrial cooking mixer for your facility. We offer extensive after-sales support, including technical training for your staff, ongoing maintenance, and access to a wide range of spare parts. BAK’s commitment to customer success extends beyond installation—we are dedicated to maximizing your uptime, optimizing your process efficiency, and ensuring your investment delivers long-term value. For added peace of mind, we invite you to review our Warranty and Service program, which underscores our dedication to your operational continuity.

Schedule a meeting to discuss your production goals and find the right cooking mixer for your facility. Our experts are ready to help you achieve greater efficiency, product consistency, and food safety in your processing operations.