Series MG

Mixer Grinders

Bowl Volume

450 - 1500

Liters

Max Mixing Capacity

744 - 2480

Pounds

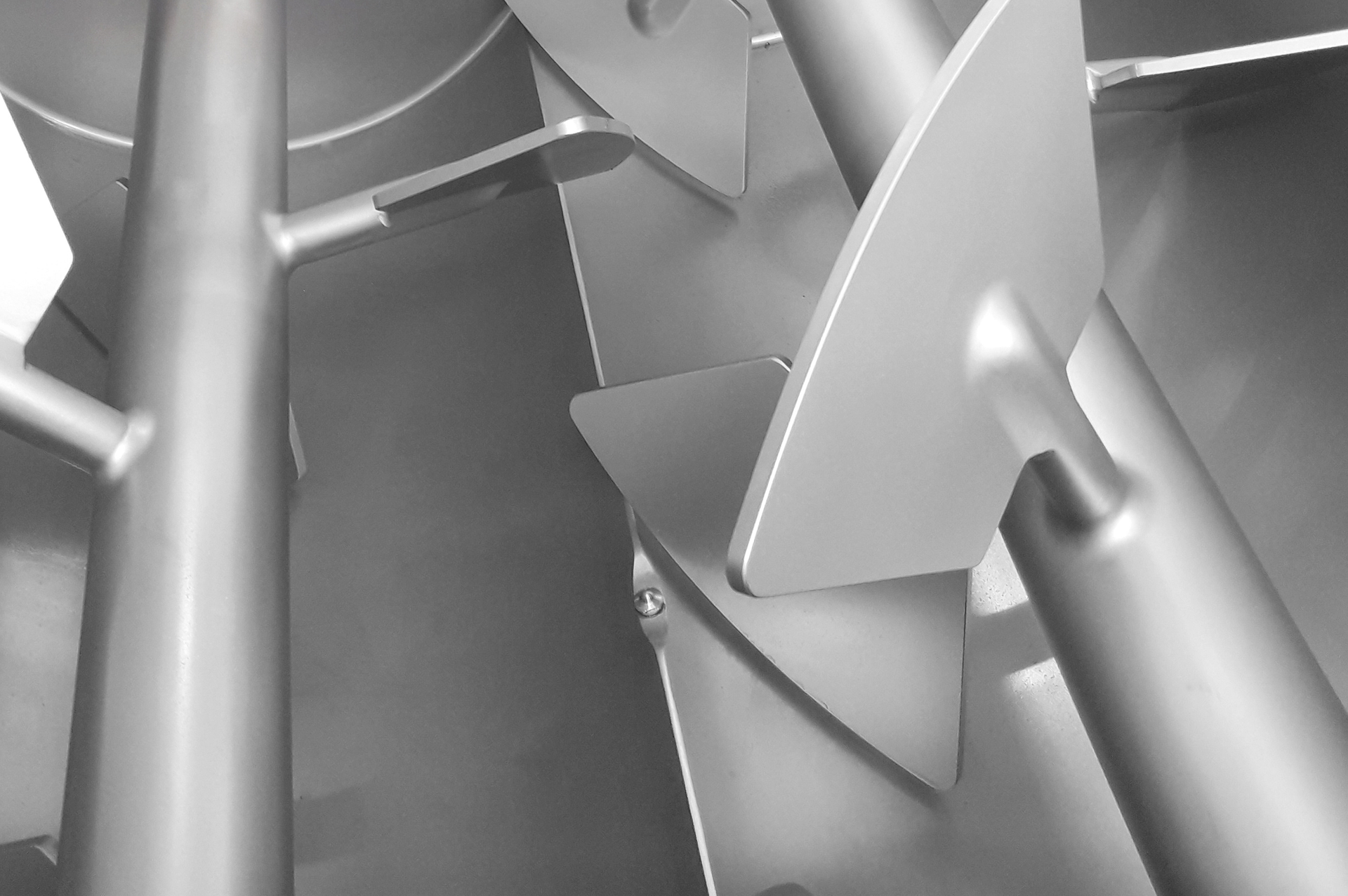

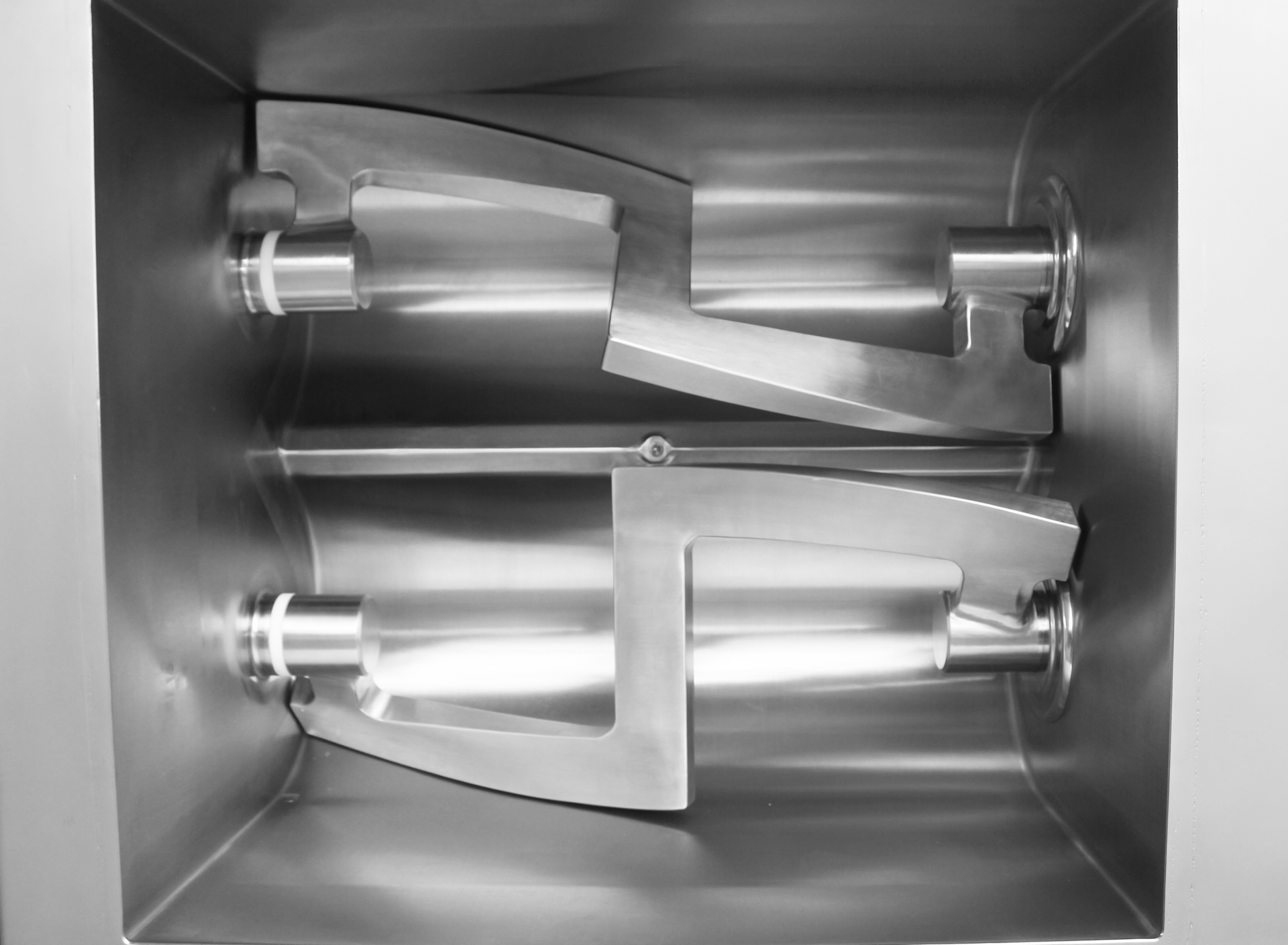

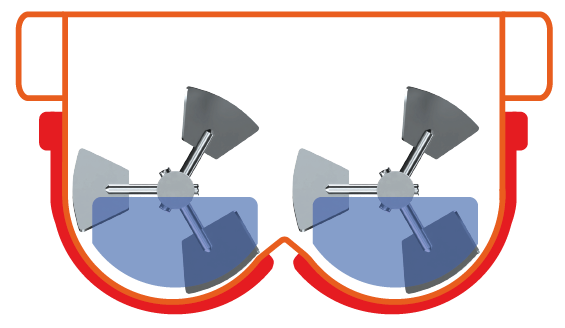

- Advanced Twin-Paddle Mixing System: The twin-paddle shaft mixing system provides gentle yet effective mixing, maintaining the ideal structure of both fatty and lean meats. It ensures up to 20% faster mixing, making it perfect for pre-minced meat and other meat products that require precise mixing and color consistency after grinding.

- Variable speed: Offers precise speed adjustments, allowing the shafts and griding auger to rotate at any desired speed within the machine's range.

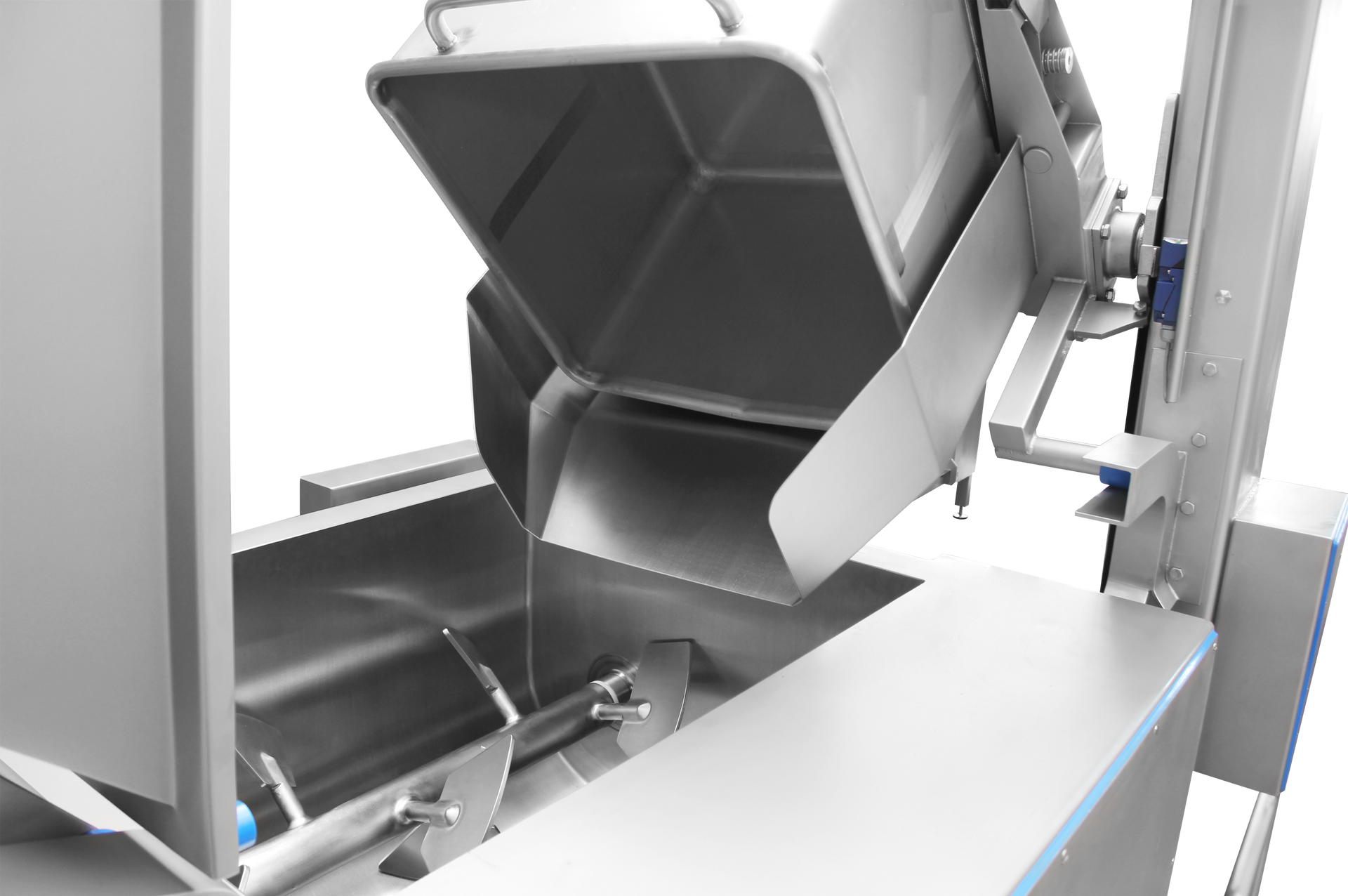

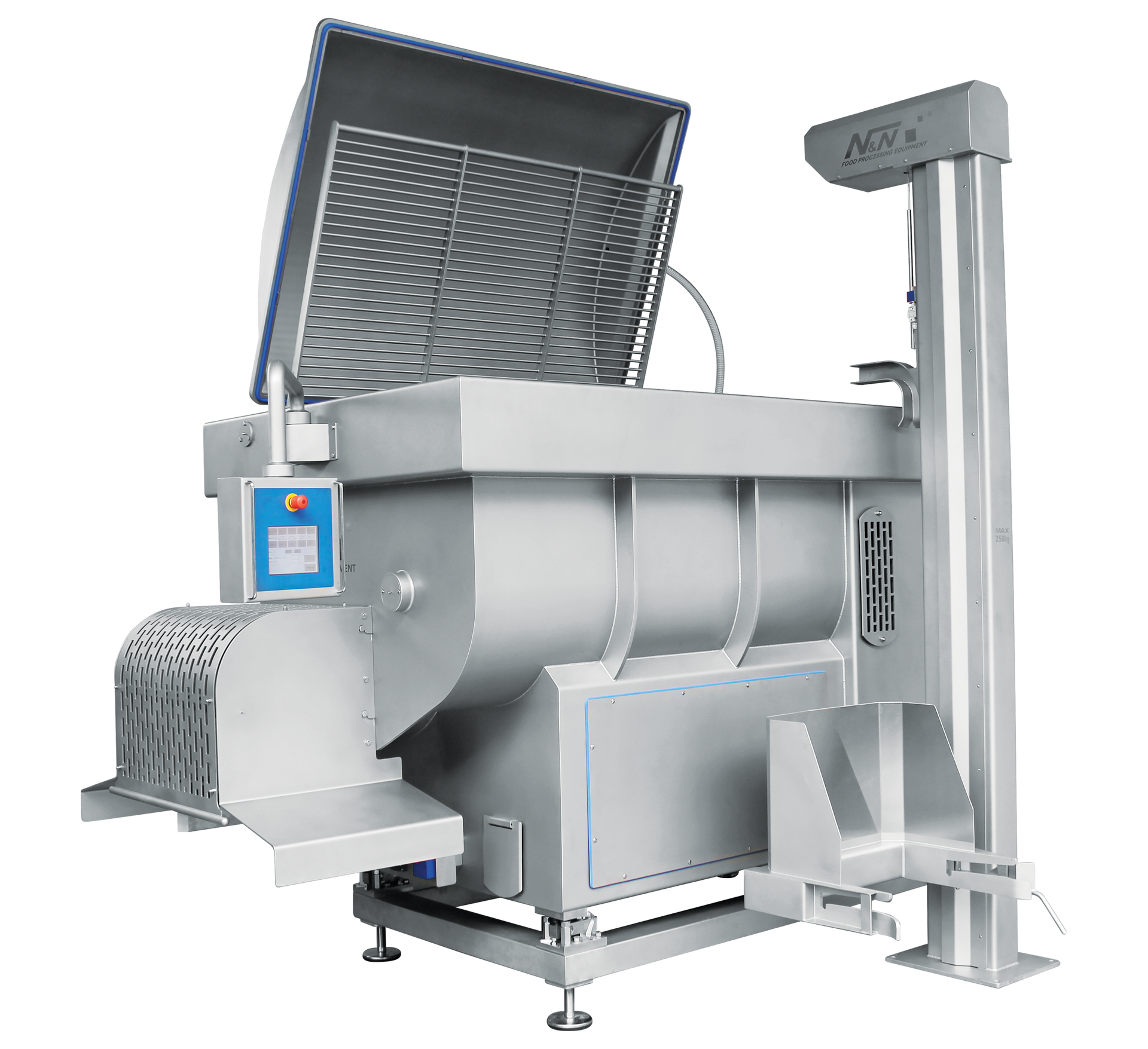

- Direct-Flow Grinder: The MG Series features a grinder positioned directly beneath the mixer tank, allowing pre-minced meat to flow efficiently from the mixer to the grinder. Specially shaped paddles ensure quick filling, minimizing waste and streamlining the grinding process.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments. The grinding auger is machined from a single piece of stainless steel.

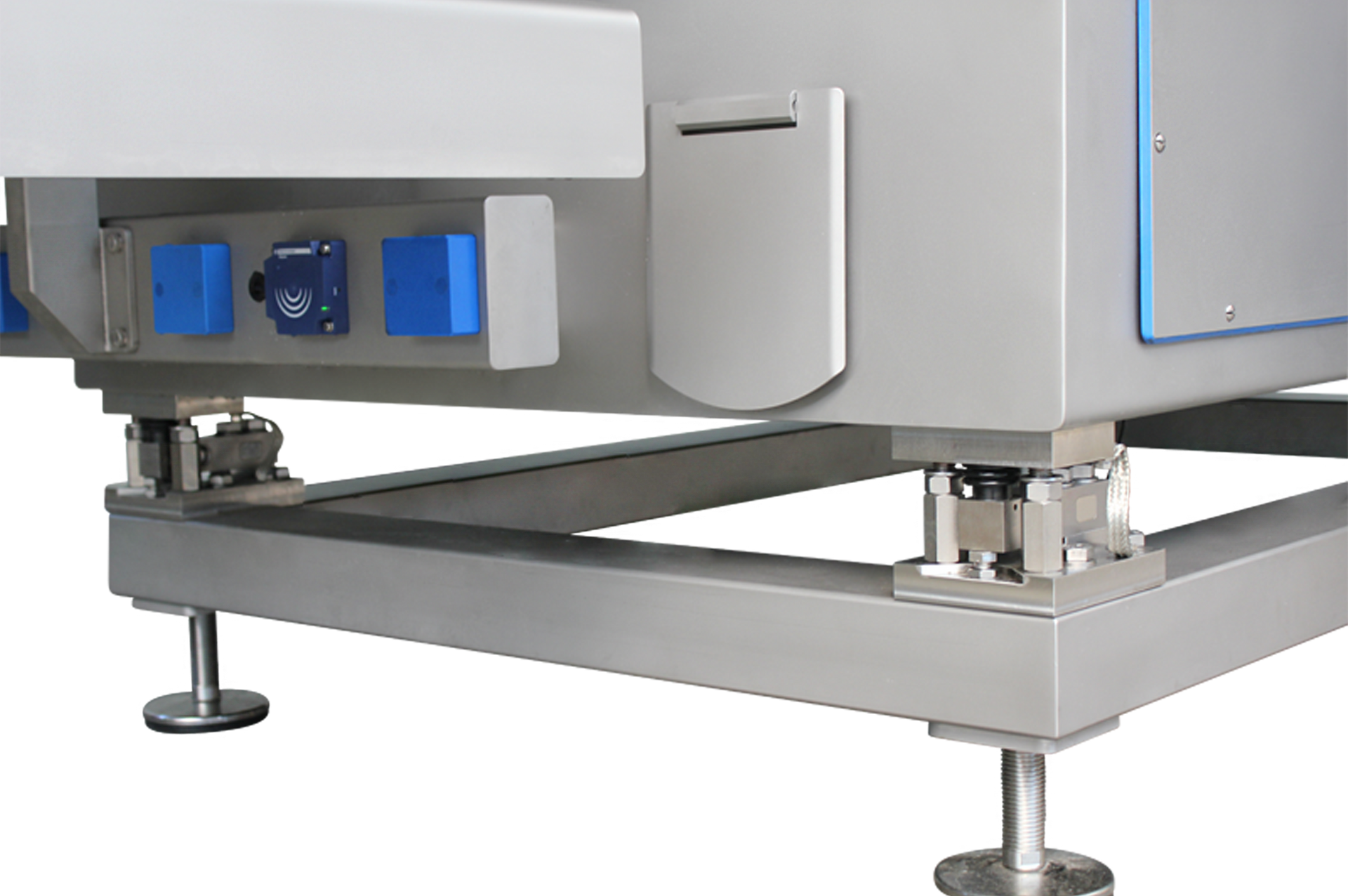

Advanced Programmable Control Panel:

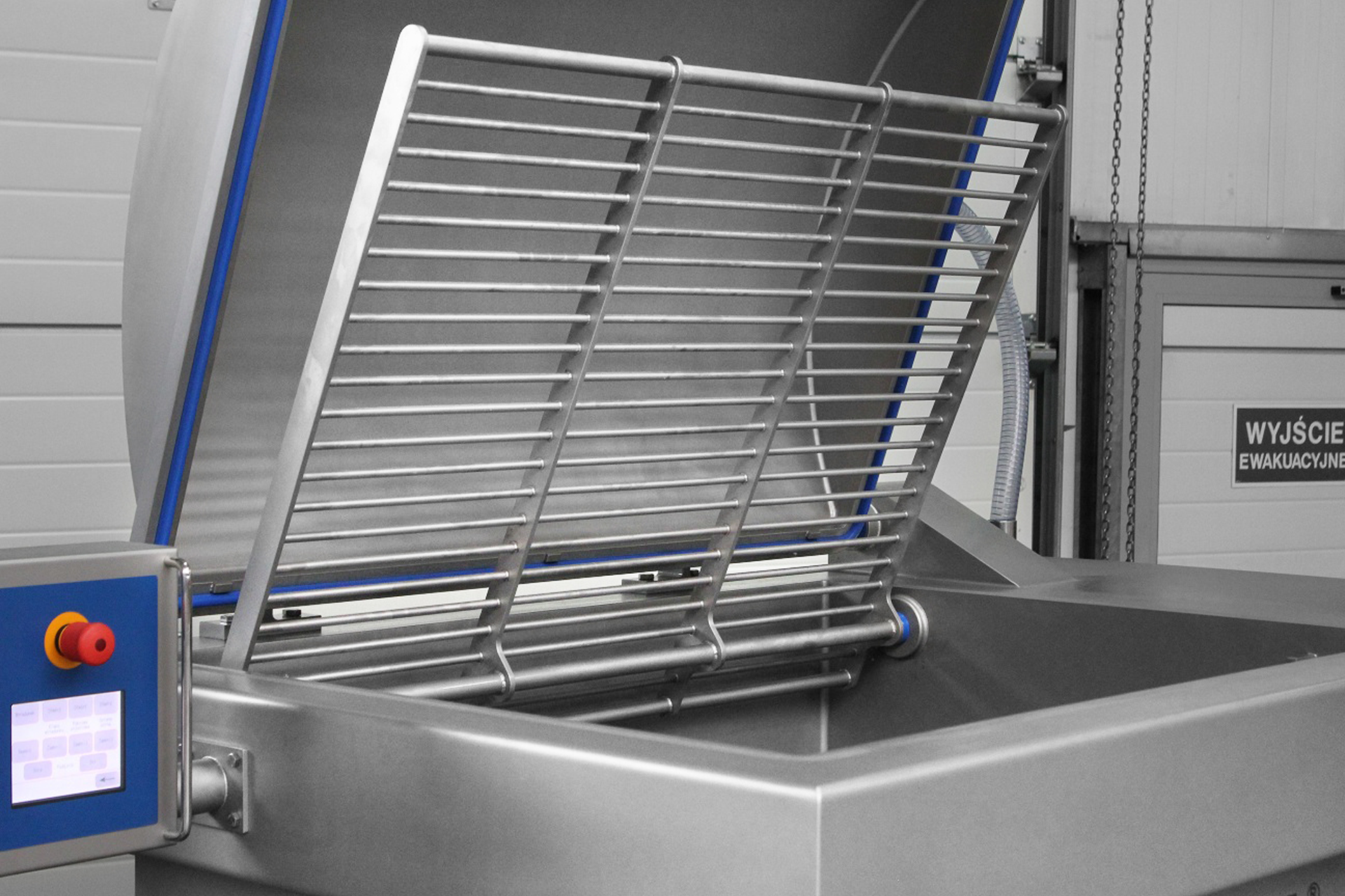

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as mixing and auger speed.

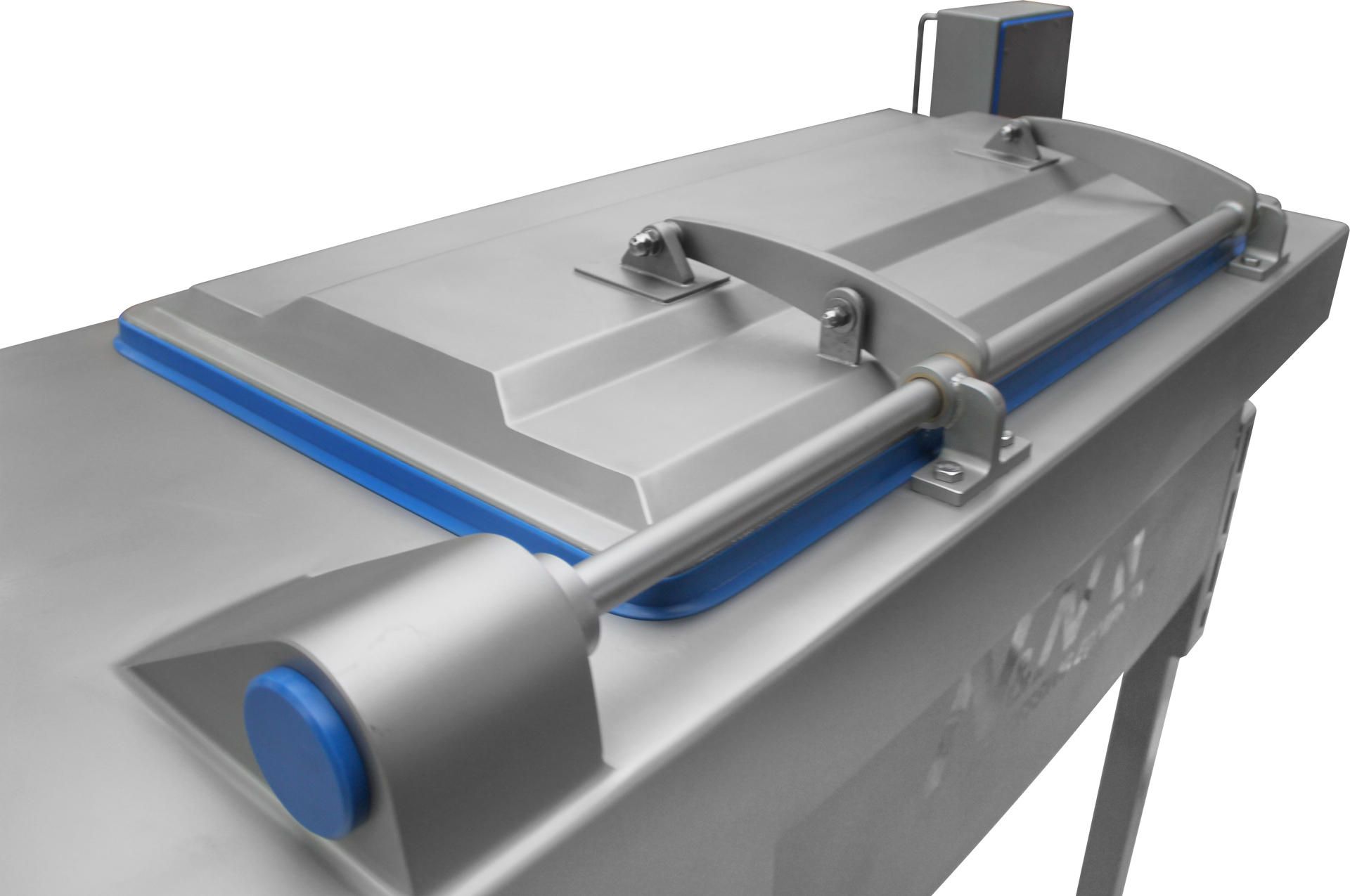

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

The MG Series mixer-grinder is designed for a wide range of applications in the food processing industry. Its innovative combination of a twin-shaft paddle mixer and a high-end grinder makes it suitable for preparing, grinding, and forming products such as pet food, sausages, burgers, and other processed foods.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

High-Speed Mixer Grinders for Modern Food Processing

What makes high-speed mixer grinders essential for food processors?

High-speed mixer grinders are indispensable in today’s food processing industry due to their ability to combine mixing and grinding in a single, streamlined operation. Mixer grinders are typically used for a secondary or final grind. This integration significantly reduces handling time, minimizes product transfers, and lowers the risk of contamination. By ensuring a consistent product texture, yield, and color, high-speed mixer grinders help processors maintain strict quality standards across a variety of applications, including meat, poultry, seafood, plant-based protein, and pet food production lines. Their efficiency and reliability are crucial for meeting the demands of high-volume, modern food processing environments.

How do they differ from standard mixing or grinding machines?

Unlike standard mixing or grinding machines, high-speed mixer grinders are engineered as integrated systems that perform both functions simultaneously. BAK’s MG Series, for example, features a twin-paddle shaft mixing system that delivers gentle yet effective mixing, preserving the structure of both fatty and lean meats. The direct-flow grinder, positioned directly beneath the mixer tank, allows pre-minced meat to move efficiently from mixing to grinding, reducing waste and accelerating throughput. Variable speed controls enable precise adjustments to both mixing and grinding speeds, offering greater flexibility and control compared to traditional equipment. These features ensure faster processing times, improved product consistency, and reduced manual intervention.

How does BAK’s equipment meet the demands of high-speed production?

BAK Food Equipment’s high-speed mixer grinders are designed to excel in demanding, high-volume production settings. The advanced twin-paddle mixing system ensures up to 20% faster mixing, while the direct-flow grinder design streamlines the transfer of product, minimizing downtime and maximizing output. Constructed entirely from stainless steel, these machines offer exceptional durability and are built to withstand the rigors of industrial food processing. The intuitive, programmable control panel allows operators to create and store up to 100 custom programs, optimizing performance for a wide range of products. Additional features such as easy-clean systems, fully sealed covers, and optional load cells for precise portioning further enhance hygiene, safety, and operational efficiency. These attributes make BAK’s mixer grinder machines a reliable choice for processors seeking to boost productivity while maintaining the highest standards of food safety and quality.

Key Advantages of BAK’s High-Speed Mixer Grinders

What are the main benefits of using BAK’s high-speed mixer grinders?

BAK’s high-speed mixer grinders deliver a range of benefits that make them a standout choice for food processors seeking efficiency, consistency, and durability. The advanced twin-paddle mixing system ensures gentle yet highly effective mixing, preserving the structure of both fatty and lean meats. This system achieves up to 20% faster mixing speeds compared to conventional equipment. The integration of mixing and grinding in a single machine reduces handling and labor, streamlining production and minimizing the risk of cross-contamination. Constructed entirely from stainless steel, including a single-piece machined auger, these machines are built for long-term reliability and easy maintenance, even in demanding industrial environments.

How do these machines enhance productivity and product quality?

Productivity is significantly enhanced by the synchronized paddle shafts and direct-flow grinder design. The grinder is positioned directly beneath the mixer tank, allowing pre-minced meat to flow efficiently from the mixer to the grinder, minimizing waste and expediting the process. The independently controlled shaft rotation allows for precise adjustments, resulting in a uniform product texture and consistent color retention—critical factors for high-quality processed foods. The intuitive touch screen control panel enables operators to create and store up to 100 custom programs, ensuring repeatable results and reducing the need for manual intervention. This level of automation and programmability supports consistent output and reduces the likelihood of operator error.

What technical innovations set BAK apart?

BAK’s mixer grinders are distinguished by several technical innovations. The variable speed control allows both the mixing shafts and grinding auger to operate at any desired speed within the machine’s range, providing unmatched flexibility for different product requirements. The direct-flow grinder and specially shaped paddles ensure quick filling and efficient product transfer, while optional features such as load cells, temperature monitoring, and water dosage systems further enhance process control and product consistency. The fully sealed cover is ideal for mixing dusty products, and the easy clean system simplifies routine maintenance. These innovations, combined with robust stainless steel construction and a user-friendly programmable interface, position BAK’s high-speed mixer grinders at the forefront of industrial mixer grinder benefits, high speed mixing equipment, stainless steel food processing machinery, and automated mixing systems.

Other Applications in Food Processing

What industries and products benefit from high-speed mixer grinders?

High-speed mixer grinders, such as the MG Series from BAK Food Equipment, are engineered for versatility and performance across a broad spectrum of food processing industries. These machines are widely used in meat processing facilities for products like ground meat, sausages, and burgers, where precise mixing and consistent grinding are essential for product quality and yield. Beyond traditional meat applications, BAK’s mixer grinders are also highly effective in the production of pet food, where uniform texture and ingredient distribution are critical for both nutritional value and consumer appeal. Additionally, the growing demand for plant-based protein blends has made these machines indispensable in plant-based food processing, as they can handle a variety of ingredients while maintaining the desired structure and consistency.

How versatile are BAK’s machines across different processing needs?

BAK’s mixer grinders are designed to meet the needs of processors handling both high-volume production and specialty batches. The advanced twin-paddle mixing system ensures gentle yet thorough mixing, preserving the integrity of both fatty and lean components in recipes. This system, combined with variable speed controls and a direct-flow grinder, allows operators to fine-tune the process for a wide range of products—from traditional meat blends to innovative plant-based formulations. The programmable control panel supports up to 100 custom programs, enabling quick changeovers and consistent results across diverse recipes. Whether producing large batches of pet food or small runs of specialty sausages, BAK’s equipment delivers reliable, repeatable performance. The robust, stainless steel construction and easy-clean design further enhance their suitability for demanding environments, making them a preferred choice for food mixing and grinding applications in modern processing plants.

Choosing the Right High-Speed Mixer Grinder

What factors should be considered when selecting a high-speed mixer grinder?

Selecting the right high-speed mixer grinder for your food processing operation requires a careful evaluation of several key factors. First, assess the bowl volume and maximum mixing capacity to ensure the equipment can handle your production requirements. BAK Food Equipment’s MG Series, for example, offers bowl volumes ranging from 450 to 1500 liters and mixing capacities from 744 to 2480 pounds, making them suitable for wide range of operations.

Next, consider the mixing system. The advanced twin-paddle shaft mixing system in the MG Series provides gentle yet effective mixing, preserving the structure of both fatty and lean meats while ensuring up to 20% faster mixing. This is particularly important for products that require precise mixing and color consistency, such as sausages and burgers.

Variable speed control is another critical feature. The ability to adjust shaft and auger speeds allows for greater flexibility and precision in processing different products. Additionally, look for a direct-flow grinder design, which streamlines the transfer of pre-minced meat from the mixer to the grinder, reducing waste and improving efficiency.

Durability and ease of maintenance should not be overlooked. Industrial-grade stainless steel construction ensures long-lasting performance, while features like intuitive touch screen controls and easy-clean systems simplify operation and upkeep.

How to match a high-speed mixer grinder with your plant’s needs?

To tailor your choice of high-speed mixer grinder to your plant’s specific needs, start by analyzing your typical product output and processing volumes. For high-throughput facilities, larger models like the MG 1500/200, with a 1500-liter bowl and 2480-pound capacity, may be ideal. For smaller or more specialized operations, a model with a lower capacity may be more appropriate.

If you require finely tuned control over your process, features such as load cells for precise portioning, temperature monitoring, and water dosage systems can further enhance consistency and product quality.

Evaluate your workflow and facility layout. Options like pneumatic lids, loading systems, and fully sealed covers can improve efficiency and safety, especially when handling dusty or challenging products. The flexibility to choose between fixed, mobile, or free-standing loading systems ensures the equipment integrates seamlessly into your existing production line.

What are the common mistakes to avoid in choosing a mixer grinder?

One common mistake is underestimating the required capacity, which can lead to production bottlenecks and increased downtime. Always select a mixer grinder that not only meets your current needs but also allows for future growth.

Another pitfall is overlooking the importance of advanced features such as variable speed control, programmable settings, and easy-clean systems. These features can significantly impact product quality, operational efficiency, and maintenance costs over time.

Finally, avoid focusing solely on price. While budget is important, investing in a high-quality, durable mixer grinder with the right features for your application will deliver better long-term value and performance for your processing plant.

Partner with BAK for High-Speed Mixing and Grinding Solutions

Why choose BAK Food Equipment for high-speed mixer grinders?

BAK Food Equipment stands out as a trusted partner for processors seeking high-speed mixer grinders that deliver both performance and reliability. Our MG Series industrial mixer grinders are engineered with advanced twin-paddle mixing systems, ensuring gentle yet effective mixing that preserves the structure of both fatty and lean meats. This technology enables up to 20% faster mixing, making it ideal for applications where speed and product consistency are critical. The direct-flow grinder, positioned directly beneath the mixer tank, streamlines the process by allowing pre-minced meat to move efficiently from mixing to grinding, minimizing waste and maximizing throughput.

How does BAK support performance, reliability, and customization for processors?

At BAK Food Equipment, we are committed to precision engineering and robust construction. Our mixer grinders are built entirely from stainless steel, including a grinding auger machined from a single piece, ensuring exceptional durability and long-lasting performance in demanding food production environments. The intuitive, programmable control panel allows operators to create and store up to 100 custom programs, adjusting variables such as mixing and auger speed for tailored results. Hygiene and easy maintenance are at the forefront of our design, with features like easy-clean systems and fully sealed covers to contain dust and facilitate routine cleaning. For processors with unique requirements, we offer a range of options including temperature monitoring, water dosage systems, load cells for precise portioning, and flexible loading solutions—ensuring your mixer grinder is perfectly suited to your production needs.

Ready to optimize your food production efficiency with automated mixing solutions? Contact BAK Food Equipment to discuss your high-speed mixing and grinding goals. Our team is ready to provide tailored recommendations and help you achieve the highest standards in commercial food processing machinery.

Food Mixer Grinder FAQs

What is a high-speed mixer grinder used for in food processing?

A high-speed mixer grinder is a versatile piece of food processing equipment that combines both mixing and grinding functions in a single, continuous process. In food processing, these machines are used for secondary or final grinding in the preparation of a variety of products, including ground meats, sausages, pet foods, and plant-based proteins.

How do high-speed mixer grinders differ from standard food mixers or grinders?

High-speed mixer grinders, such as those in BAK’s MG Series, stand apart from standard mixers or grinders by integrating both functions into one machine. While traditional equipment may require separate steps for mixing and grinding, BAK’s high-speed mixer grinders use a twin-paddle shaft mixing system and a direct-flow auger. The direct-flow grinder positioned beneath the mixer tank ensures efficient transfer of pre-minced meat, streamlining the process and reducing waste.

What industries use BAK’s high-speed mixer grinders?

BAK’s high-speed mixer grinders are widely used across several food processing sectors, including meat, poultry, seafood, pet food, and alternative protein production. Their robust construction and advanced programmable controls make them suitable for both large-scale industrial operations and specialty applications that require precise mixing and grinding. The flexibility and reliability of these machines make them a preferred choice for processors seeking to enhance productivity and product quality.

How does BAK’s high-speed mixer grinder improve product quality?

The advanced twin-paddle mixing system in BAK’s mixer grinders ensures gentle yet effective mixing, maintaining the ideal structure of both fatty and lean meat components. Variable speed controls allow operators to fine-tune the mixing intensity, which helps preserve product structure, enhance color consistency, and increase yield. The result is a more uniform product with improved texture and appearance, meeting the high standards demanded by today’s food industry.

What maintenance requirements do high-speed mixer grinders have?

BAK’s high-speed mixer grinders are engineered for easy maintenance and sanitation. The machines feature smooth, polished stainless-steel surfaces and tool-free access to key components, making routine cleaning straightforward. Optional features such as the Easy Clean system further simplify upkeep and ensure sanitary operation. These design elements help processors maintain high hygiene standards while minimizing downtime for maintenance.

Can BAK’s high-speed mixer grinders be customized for specific processing needs?

Yes, BAK offers a range of customizable options to tailor our high-speed mixer grinders to specific production requirements. Available features include temperature monitoring, load cells for precise portioning, automated liquid dosing systems, and a choice of fully sealed or openwork covers. Additional options such as jacketed bowls for heating or cooling, and various loading systems ensure that each machine can be configured to match the unique needs of any processing environment.