Custom Automation Solutions Tailored to Your Production Line

Revolutionize your production line with tailored automation solutions from BAK Food Equipment, designed to meet your unique processing needs.

Introduction to Custom Food Automation Equipment

What is custom food automation equipment?

Custom food automation equipment refers to productivity-enhancing machinery specifically designed to address the unique requirements of a food processor’s production line. Unlike standard, off-the-shelf solutions, custom automated food processing systems are developed with a deep understanding of each customer’s process, product, and operational goals. This can involve the creation of entirely new equipment—such as BAK Food Equipment’s pass through tumbler—or the integration of multiple machines into tailored processing lines that utilize unified human-machine interfaces (HMI) and conveyor systems. The result is a solution that fits seamlessly into existing operations while addressing specific production challenges.

How does BAK design tailored systems to meet unique production needs?

At BAK Food Equipment, every custom automation solution begins with a thorough engagement process to understand the customer’s production workflow, capacity requirements, and desired outcomes. BAK’s approach is highly collaborative, ensuring that the final system is not only technically sound but also practical for day-to-day operations. The flexibility of BAK’s offerings allows for a range of solutions, from semi-automated systems—such as tumbling lines that assist operators—to fully automated lines that integrate smoking, grinding, mixing, and chilling processes. By leveraging advanced automation and control technologies, BAK is able to design and implement tailored processing lines that maximize throughput, minimize manual intervention, and ensure consistent product quality.

Why are automated solutions essential for modern food processors?

Automated food processing systems are essential for today’s food processors due to their significant impact on efficiency, consistency, and food safety. Automation reduces the reliance on manual labor, which not only lowers operational costs but also minimizes the risk of human error and contamination. Automated systems deliver consistent results, ensuring that every batch meets the same high standards for quality and safety. Additionally, automation enables processors to scale production more easily and respond to changing market demands. For these reasons, custom food automation equipment from BAK Food Equipment is a critical investment for processors seeking to remain competitive and compliant in a rapidly evolving industry.

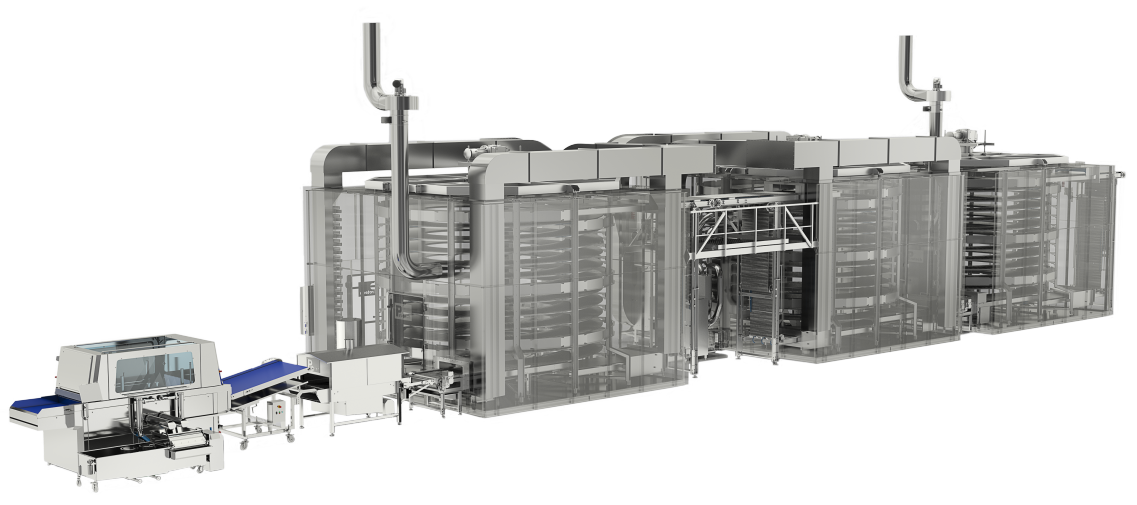

Automated Spiral Smoking, Cooking & Chilling Lines

How do spiral smoke systems improve over batch smokehouses?

Spiral smoke systems represent a significant advancement over traditional batch smokehouses, particularly for high-volume operations. Unlike batch systems, which require manual loading, unloading, and often combing or hanging of products, spiral smokehouses use a continuous conveyor system that moves products through the smoking, cooking, and chilling processes automatically. This design eliminates the need for manual handling, reducing labor requirements and minimizing the risk of product damage. The spiral configuration also ensures consistent exposure to smoke and heat, resulting in uniform product quality and increased yield of #1 product. With natural smoke system design, these automated smoking systems can achieve throughput capacities exceeding 10,000 pounds per hour for products like bacon, making them ideal for industrial bacon processing and other large-scale protein applications.

What cost savings and efficiency gains do they provide?

Automated spiral smokehouses deliver substantial cost savings and efficiency improvements. By automating the entire process, labor costs are significantly reduced, as fewer operators are needed to manage the line. The continuous flow design maximizes floor space efficiency, allowing for higher production volumes within a smaller footprint compared to traditional batch systems. Utility savings are also realized through optimized smoke and heat distribution, which reduces energy consumption and improves overall operational efficiency. Additionally, the consistent processing environment minimizes product loss, further enhancing profitability. These systems are engineered for easy cleaning and maintenance, contributing to lower downtime and increased uptime for production lines.

What products can be processed with spiral systems?

Spiral smokehouses are highly versatile and can be customized to handle a wide range of products. While they are particularly well-suited for industrial bacon processing, they are also ideal for other proteins such as salmon, ribs, and various deli meats. Customization options include adjustable throughput rates, the number of spirals, smoke density controls, and the ability to use either natural or liquid smoke, allowing processors to tailor the system to their specific product requirements. This flexibility makes spiral smokehouses a valuable asset for processors seeking to expand their product offerings or improve the quality and consistency of their existing lines.

Automated Mixing & Grinding Lines

What advantages do automated mixing & grinding systems offer?

Automated mixing and grinding systems deliver significant benefits to food processors seeking to optimize their production lines. By leveraging microprocessor-controlled customization, these systems allow for precise control over mixing and grinding parameters, ensuring consistent product quality and repeatability. Scalability is another key advantage, as automated lines can be tailored to accommodate both small-batch and high-volume production, adapting to changing business needs. Integration with grinders, mixers, emulsifiers, mix-cook units, and metal detection equipment streamlines the entire process, resulting in higher throughput, reduced labor requirements, and improved operational efficiency. Additionally, automated systems are designed for easier cleaning and maintenance, minimizing downtime and supporting stringent hygiene standards.

How does integration improve quality and safety?

The integration of automated mixing and grinding equipment with other processing units—such as emulsifiers, cookers, and metal detection systems—enhances both product quality and food safety. Automated controls ensure that each batch is processed under optimal conditions, reducing the risk of human error and variability. Integrated metal detection equipment can identify and remove foreign objects or contaminants, further safeguarding product integrity. Consistent processing parameters also help maintain uniform texture, flavor, and appearance, which is critical for brand reputation and regulatory compliance. The streamlined workflow reduces manual handling, lowering the risk of cross-contamination and supporting robust food safety protocols.

Which industries/products benefit from these lines?

Automated mixing and grinding lines are highly versatile and benefit a wide range of food processing sectors. In industrial sausage production and other meat applications, these systems ensure uniform blending and particle size, essential for quality sausages, burgers, and stuffings. The dairy industry utilizes automated lines for consistent mixing of cheese curds, yogurts, and spreads. Producers of sauces, doughs, and batters rely on these systems for homogenous blending and efficient scaling. Additionally, pet food manufacturers and processors of fresh produce benefit from the reliability and efficiency of automated mixing and grinding equipment, enabling them to meet high standards for quality and safety while maximizing productivity.

Tumbling Solutions (Semi vs Fully Automated)

What’s the difference between semi-automated and fully automated tumbling lines?

Semi-automated tumbling lines offer a lower entry point for processors looking to enhance their production without a significant upfront investment. These systems provide flexible setups that can be tailored to specific product types and batch sizes, making them ideal for facilities with variable production demands. Semi-automated tumbling lines reduce manual labor requirements, improve hygiene by minimizing direct product handling, and deliver consistent yield improvements through controlled tumbling cycles.

Fully automated tumbling lines, on the other hand, represent the next level of integration and efficiency. These systems can be seamlessly connected with other processing equipment such as injectors, brine mixers, and grinders, creating a streamlined, end-to-end solution. Fully automated lines feature advanced data tracking and reporting capabilities, allowing for precise monitoring and optimization of every batch. Product movement is optimized throughout the process utilizing conveyors and loaders, and labor needs are reduced to a minimum, supporting high-volume, continuous production environments.

How do tumbling systems improve product yield, quality, and efficiency?

Both semi-automated and fully automated tumbling systems are engineered to maximize protein extraction and moisture retention, which directly translates to higher product yield and improved texture. The controlled tumbling action ensures even distribution of marinades and seasonings, resulting in consistent flavor profiles across every batch. These systems are customizable in terms of size and capacity, and can be equipped with optional heating or chilling features to further enhance product quality and food safety. By automating key steps in the marination and tenderization process, tumbling systems also reduce processing time and minimize the risk of human error, boosting overall efficiency.

Which option is right for different production scales?

For small to mid-sized processors or those with diverse product lines, a semi-automated tumbling line offers the flexibility and scalability needed to adapt to changing production requirements. These systems are well-suited for operations looking to improve efficiency and product consistency without fully committing to automation. In contrast, fully automated tumbling lines are the preferred choice for large-scale processors seeking maximum throughput, minimal labor involvement, and comprehensive process control. These advanced systems are ideal for facilities focused on high-volume production of meat, poultry, seafood, or fruit, where integration with other automated marination systems and industrial tumblers can deliver significant operational advantages.

Benefits of BAK’s Custom Automation Solutions

How does automation impact labor costs, yield, and profitability?

BAK Food Equipment’s custom automation solutions are engineered to deliver significant improvements in labor efficiency, yield, and overall profitability for food processors. By integrating advanced automated systems such as spiral smoking, cooking, and chilling lines, companies have realized dramatic labor savings—one example being a reduction of $2.4 million annually in labor costs through the implementation of a spiral system. Automation not only reduces the need for manual labor but also ensures consistent product quality and throughput, directly contributing to higher profitability. Additionally, yield improvement equipment from BAK enables processors to achieve a higher percentage of #1 grade bacon, which can translate into millions of dollars in additional revenue each year. These solutions are tailored to each facility’s unique requirements, maximizing both operational efficiency and financial returns.

What safety and hygiene improvements do these systems provide?

Food safety automation is a core focus of BAK’s custom solutions. All equipment is constructed from high-grade stainless steel, which is inherently resistant to corrosion and easy to sanitize. The clean-in-place (CIP) design further enhances hygiene by allowing for thorough, automated cleaning cycles that minimize downtime and reduce the risk of contamination. These features not only help processors meet stringent food safety standards but also support long-term durability and reliability in demanding production environments.

How does BAK’s equipment reduce resource waste and floor space usage?

BAK’s custom automation solutions are designed to optimize resource utilization and facility layout. Automated systems precisely control the use of brine and marinade, significantly reducing waste and improving product consistency. Enhanced energy efficiency is achieved through advanced process controls and equipment design, lowering operational costs and environmental impact. Furthermore, BAK’s solutions can reduce required floor space by up to 60%, allowing processors to maximize production capacity within existing facilities. This space optimization is particularly valuable for companies looking to expand output without the need for costly facility expansions.

Choosing the Right System for Your Facility

What factors determine the right level of automation (semi vs full)?

Selecting between semi-automated and fully automated food processing systems depends on several critical factors. The type of product being processed, desired throughput, available floor space, workforce availability, and regulatory compliance requirements all play a role. For example, facilities with high-volume production targets and limited labor resources may benefit from fully automated solutions, while smaller operations or those with more variable product lines might find semi-automated systems more flexible and cost-effective. BAK Food Equipment works closely with clients to assess these variables, ensuring the chosen system aligns with both current needs and long-term business goals.

How does BAK tailor systems to different plant layouts and throughput requirements?

Every food processing facility is unique, and BAK Food Equipment recognizes the importance of designing systems that fit seamlessly into existing plant layouts. Through a consultative approach, BAK evaluates the available space, workflow patterns, and throughput targets to develop custom automation design solutions. Whether integrating an automated spiral smoking, cooking, and chilling line or a semi-automated tumbling line, BAK’s team ensures that each system is engineered for optimal efficiency and minimal disruption. This tailored approach allows for the creation of scalable processing equipment that can adapt as production demands evolve.

How can processors future-proof their operations with custom solutions?

Future-proofing a food processing operation requires more than just meeting today’s needs, it demands flexibility and scalability for tomorrow’s challenges. BAK Food Equipment specializes in tailored food production lines that are designed with expansion and adaptability in mind. By focusing on modular components and scalable system architectures, BAK enables processors to upgrade or expand their lines as market demands shift or as new products are introduced. This commitment to customization and scalable design helps ensure that investments in automation continue to deliver value well into the future.

The Value of Choosing BAK Custom Equipment

Why are BAK’s custom automation systems the future of food processing?

BAK Food Equipment’s custom automation systems represent the next generation of food processing by delivering solutions that are precisely tailored to each processor’s unique requirements. Unlike off-the-shelf machinery, BAK’s custom food processing systems are engineered to integrate seamlessly into existing production lines, addressing specific challenges and optimizing every stage of the process. This level of customization ensures that processors can achieve maximum throughput, consistent product quality, and operational flexibility—key factors in staying competitive in today’s fast-evolving food industry. With BAK Food Equipment automation, processors benefit from advanced technology that not only streamlines production but also adapts to changing market demands and regulatory requirements.

What are the long-term benefits for processors adopting automation?

Adopting industrial food automation solutions from BAK offers significant long-term advantages. First, automation drives substantial cost savings by reducing manual labor requirements and minimizing human error, which translates to lower operational expenses and fewer costly mistakes. Enhanced labor efficiency allows staff to focus on higher-value tasks, improving overall productivity and job satisfaction. Automated systems also deliver improved product quality through precise, repeatable processes that ensure consistency and food safety. Additionally, BAK’s custom solutions are designed with sustainability in mind, optimizing resource use and reducing waste throughout the production cycle. Over time, these benefits compound, resulting in a more resilient, profitable, and environmentally responsible operation.