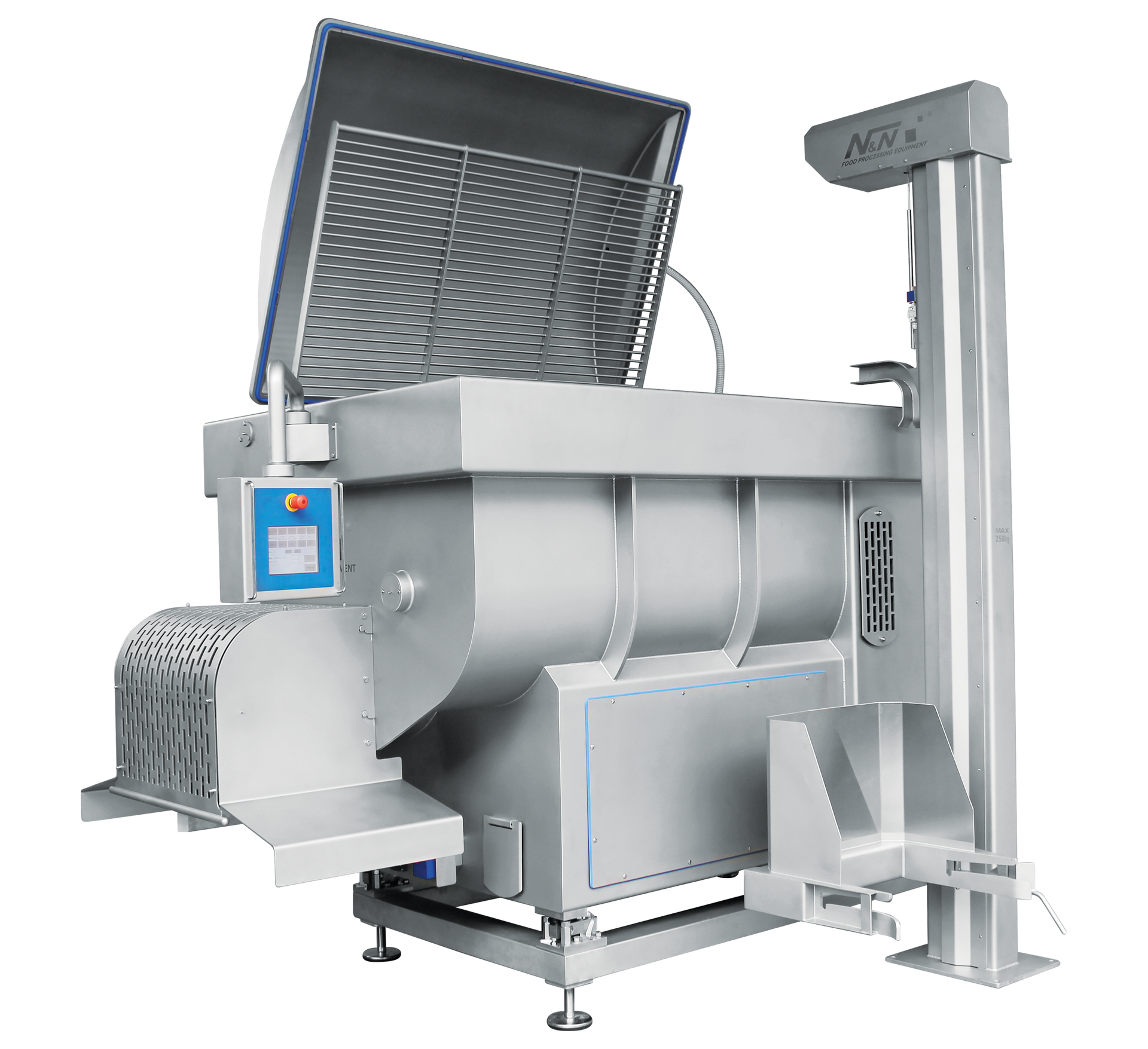

Series MIX SZ/SZV

Parallel Z-Type Shaft Mixers

Bowl Volume

300 - 1500

Liters

Max Mixing Capacity

450 - 2200

Lbs

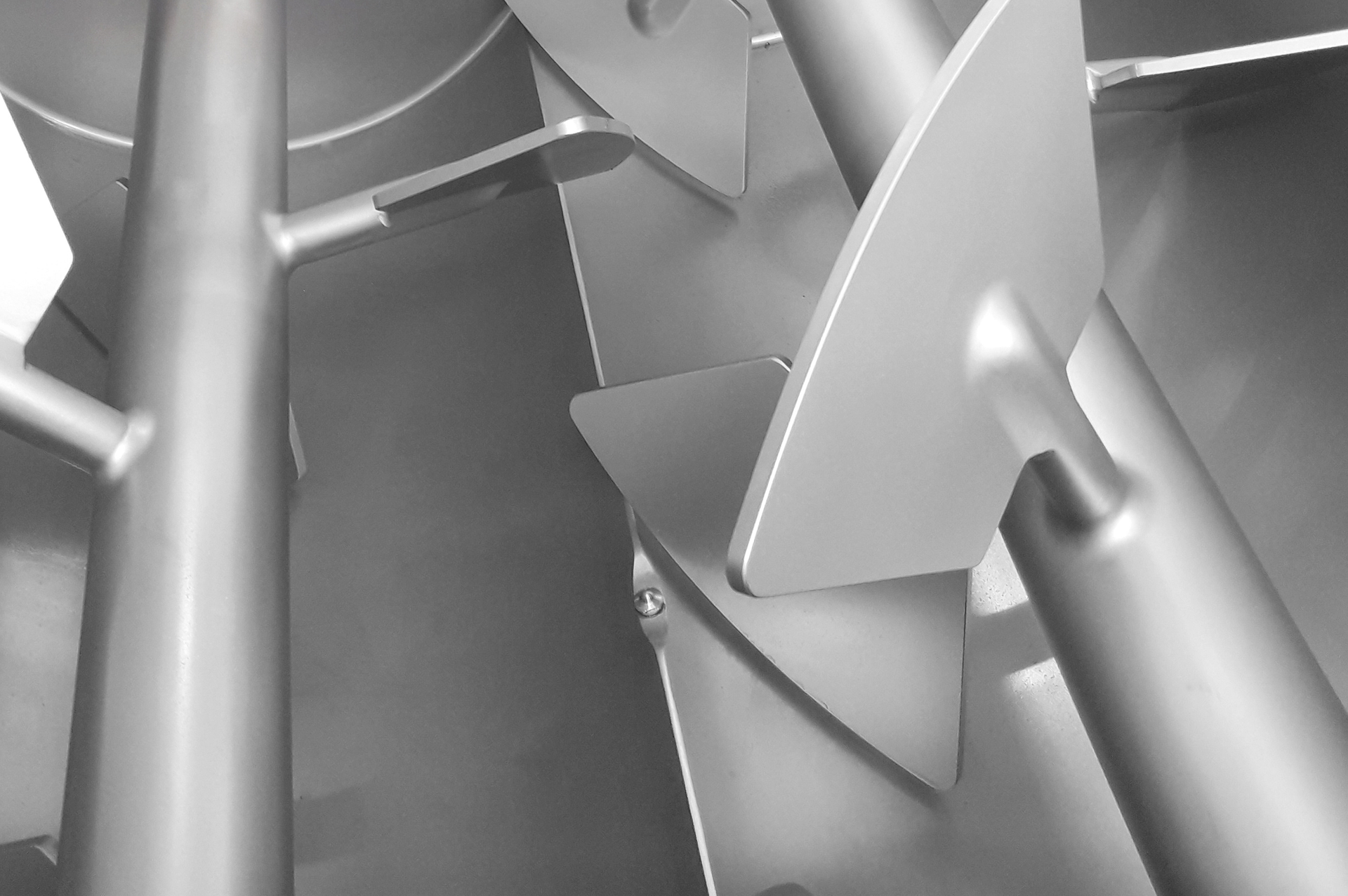

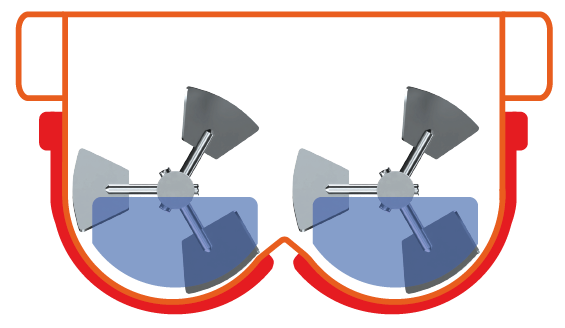

- Dual Parallel Z-Type Shafts:

Features dual parallel Z-type shafts at the same height, allowing independent adjustment of speed and rotation direction for each shaft, providing precise and flexible mixing and kneading for the most demanding and heavy masses.

- Vacuum Option:

Equipped with a reinforced bowl and airtight top cover, allowing up to 99% vacuum, which enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming.

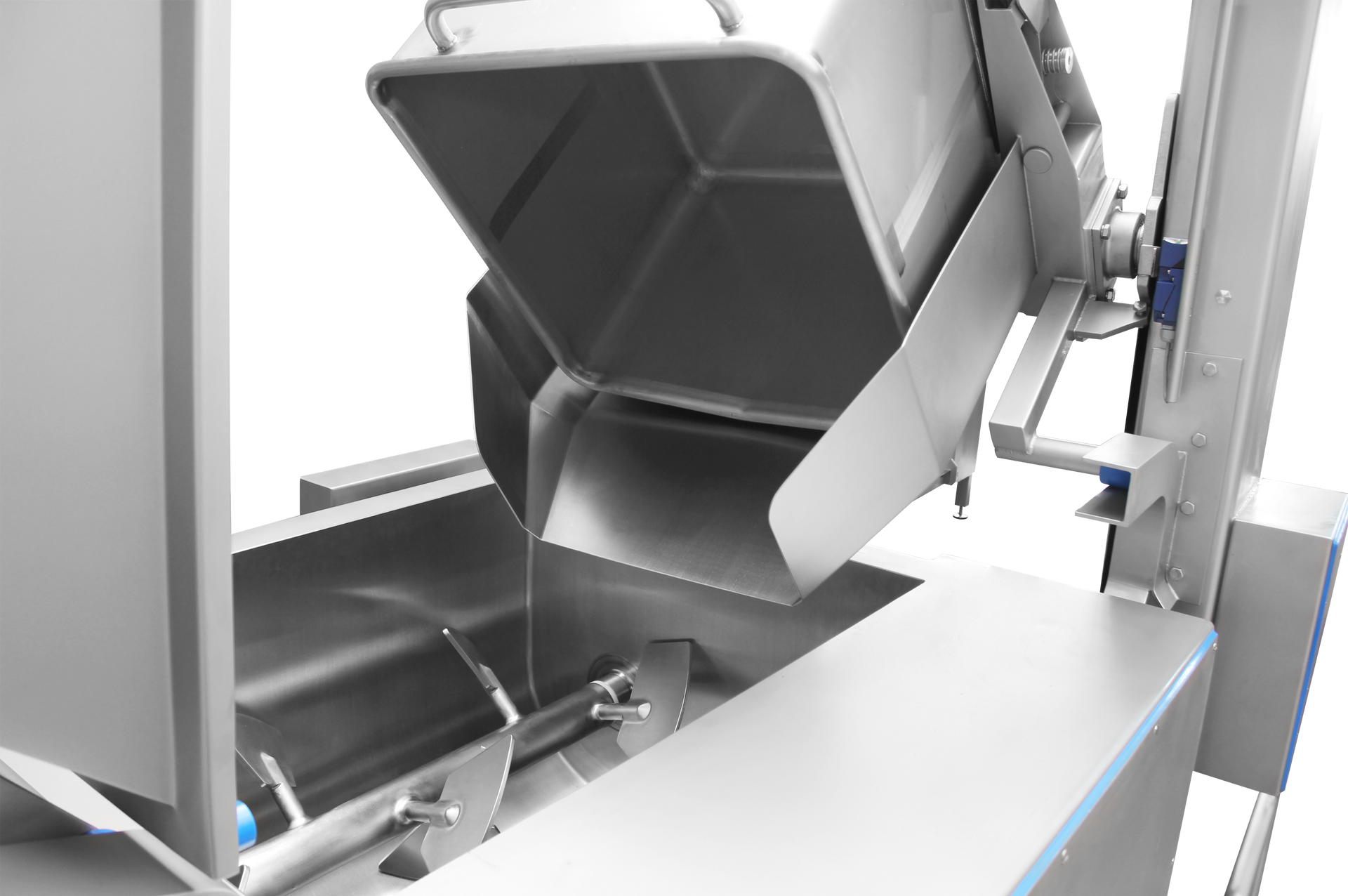

- Hydraulic Unloading : Fitted with a hydraulic system for opening the mixing chamber cover and tilting the bowl for unloading, allowing quick and easy emptying.

- Variable speed:

Offers precise speed adjustments, allowing the shafts to rotate at any desired speed within the machine's range.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

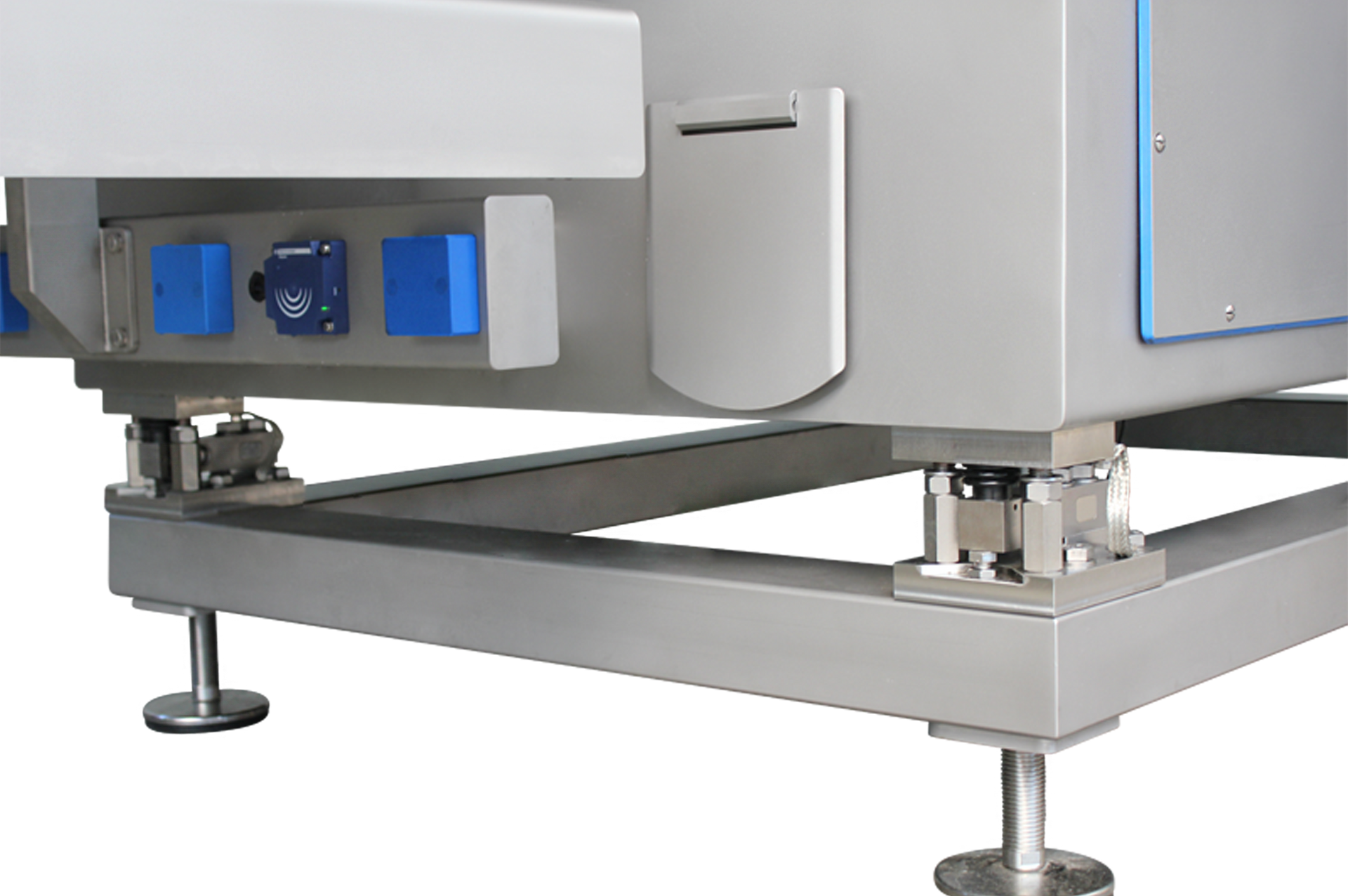

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as shaft rotation speed, shaft rotation direction, and vacuum level.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient

Technical Information

Mix 300 SZ

Mix 300 SZV

Applications

The N&N MIX SZ and MIX SZV series mixers are designed for intensive mixing and kneading of dense mixtures, making them ideal for producing bakery and confectionery products like maturing dough, protein bars, and bouillon cubes.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Series MIX SZ/SZV Parallel Z-Type Shaft Mixers

What is the Series MIX SZ/SZV mixer and how does it work?

The Series MIX SZ/SZV mixers are high-performance parallel Z-type shaft mixers engineered for the most demanding industrial mixing and kneading applications. These mixers feature dual parallel Z-type shafts positioned at the same height within the mixing chamber. Each shaft can be independently controlled for both speed and rotation direction, allowing operators to precisely tailor the mixing process to the specific requirements of dense or heavy mixtures. This flexibility ensures optimal product consistency and thorough ingredient integration, even with challenging materials.

A key differentiator of the SZV models is their advanced vacuum mixing capability. With a reinforced bowl and airtight top cover, these mixers can achieve up to 99% vacuum. This vacuum environment enhances protein extraction, improves liquid absorption, ensures even distribution of spices and additives, and eliminates air bubbles before further processing steps such as emulsification, filling, or forming. The result is a superior product texture, density, and overall quality.

What makes BAK’s N&N mixers stand out from competitors?

BAK’s N&N mixers are distinguished by their robust, all-stainless-steel construction, ensuring exceptional durability and long-lasting performance in demanding industrial environments. The mixers are equipped with a hydraulic system for effortless opening of the mixing chamber and tilting of the bowl for quick unloading, streamlining production workflows. Operators benefit from an advanced programmable control panel with an intuitive touch screen, allowing the creation and storage of up to 100 custom programs. Variables such as shaft speed, rotation direction, and vacuum level can be precisely adjusted and saved for repeatable, high-quality results.

Additionally, these mixers are designed for easy cleaning and maintenance, supporting food safety and operational efficiency. BAK Food Equipment’s expertise as a trusted supplier in North America ensures that customers receive not only top-tier industrial kneading equipment but also reliable support and industry-leading solutions tailored to their production needs.

Key Features and Performance Advantages

What are the defining technical features of the MIX SZ and MIX SZV models?

The MIX SZ and MIX SZV parallel Z-type shaft mixers from BAK Food Equipment are engineered for high-performance mixing and kneading of highly dense products. At the core of their design are dual parallel Z-type shafts, positioned at the same height within the mixing chamber. Each shaft operates independently, with variable speed and rotation direction, allowing for precise control over the mixing process. This configuration ensures thorough and uniform blending, even with the most challenging mixtures.

A standout feature of the MIX SZV model is its vacuum capability. The reinforced, airtight bowl and top cover enable the mixer to achieve up to 99% vacuum. This advanced feature enhances protein extraction, improves liquid absorption, ensures even distribution of spices and additives, and eliminates air bubbles prior to downstream processes such as emulsification, filling, or forming.

Both models are equipped with a hydraulic unloading system, which includes a hydraulically operated lid and a tilting bowl. This system streamlines the discharge process, making it quick and efficient while minimizing manual labor and reducing downtime between batches.

The mixers also feature an advanced programmable control panel with a user-friendly touchscreen interface. Operators can create and store up to 100 custom mixing programs, adjusting variables such as shaft speed, rotation direction, and vacuum level to meet specific product requirements.

Constructed entirely from industrial-grade stainless steel, the MIX SZ and MIX SZV mixers are built for durability, hygiene, and long service life in demanding production environments. Routine cleaning and maintenance are simplified by accessible components and the optional Easy Clean system.

How do these features improve processing efficiency and product quality?

The technical innovations in the MIX SZ and MIX SZV models directly translate to improved processing efficiency and superior product quality. The independent, variable-speed Z-type shafts provide optimal mixing action, ensuring that all ingredients are evenly incorporated, regardless of batch size or product density. This results in consistent product texture and quality, batch after batch.

The vacuum option available in the MIX SZV model is particularly beneficial for applications requiring an extremely homogenous product and minimal air content. By removing air from the mixture, the vacuum system enhances the density and stability of the final product, reduces oxidation, and extends shelf life. This is especially valuable in the production of bakery doughs, protein bars, and other products where texture and appearance are critical.

The hydraulic unloading system not only accelerates the emptying process but also reduces the risk of product contamination and operator injury, supporting both food safety and workplace efficiency. The programmable mixer controls allow for repeatable, automated production cycles, minimizing human error and ensuring that every batch meets exacting standards.

Finally, the robust stainless steel construction and easy-clean design reduce maintenance time and costs, while supporting compliance with stringent hygiene requirements in food processing environments. Together, these features make the MIX SZ and MIX SZV mixers a reliable choice for manufacturers seeking to optimize their mixing operations and deliver high-quality products consistently.

Partner with BAK for Advanced Mixing Solutions

Why choose BAK for Z-type mixing equipment?

Our commitment to engineering precision, hygiene, and efficiency ensures that every piece of equipment we provide is designed to meet the rigorous demands of modern food production environments. The N&N MIX SZ and MIX SZV series mixers are built entirely from stainless steel, offering exceptional durability and long-lasting performance. With features such as dual parallel Z-type shafts, variable speed control, and advanced programmable control panels, our mixers deliver precise, flexible, and repeatable results for even the most challenging mixing and kneading applications.

How does BAK support customers beyond equipment sales?

At BAK Food Equipment, our relationship with customers extends far beyond the initial sale. We offer comprehensive support throughout the entire lifecycle of your equipment, including professional installation, operator training, and responsive after-sales service. Our team of specialists works closely with you to ensure seamless integration of your new mixer into your production line, maximizing uptime and productivity. We also provide ongoing technical support and maintenance guidance to help you get the most out of your investment.

Schedule a meeting with a BAK equipment specialist to discuss your mixing needs and discover how our expertise and technology can elevate your production capabilities.

FAQs: Series MIX SZ/SZV Parallel Z-Type Shaft Mixers

What is a Z-type mixer?

A Z-type mixer is an industrial mixing machine that utilizes two parallel Z-shaped shafts. These shafts rotate in opposite directions at adjustable speeds, creating a powerful kneading and blending action. This design is particularly effective for processing highly dense materials such as doughs, confectionery fillings, protein bars, and other challenging food products.

How does a Z-type mixer work?

The core of the Z-type mixer’s performance lies in its dual parallel shafts, which can be independently controlled for both speed and direction. As the Z-shaped blades rotate, they fold and shear the ingredients, ensuring complete integration of all components. The MIX SZV model enhances this process with vacuum capability, allowing up to 99% vacuum within the mixing chamber.

What are the benefits of vacuum mixing?

Vacuum mixing, as featured in the MIX SZV model, offers several advantages. By removing air from the mixture, vacuum mixing increases product density and improves protein extraction, which is essential for texture and structure in products like bakery doughs and protein bars. It also enhances color and texture, and eliminates air bubbles that could compromise product quality during forming or filling. The ability to achieve up to 99% vacuum ensures consistent, high-quality results batch after batch.

What is the difference between the MIX SZ and MIX SZV models?

Both the MIX SZ and MIX SZV models are equipped with dual parallel Z-type shafts and hydraulic unloading systems for efficient product discharge. The key distinction is that the MIX SZV model features a reinforced, airtight bowl and top cover, enabling vacuum mixing up to 99%.

What types of products can Z-type mixers process?

Z-type mixers are engineered for intensive mixing and kneading of highly dense products. They are ideal for bakery and confectionery applications such as maturing dough, marzipan, protein bars, and bouillon cubes. Additionally, these mixers are well-suited for plant-based and ready-meal production, where uniformity and texture are paramount.

How is product discharge handled?

Both the MIX SZ and MIX SZV models feature a hydraulic system that opens the mixing chamber cover and tilts the bowl for unloading. This design ensures quick, complete discharge of the mixed product, minimizing downtime and facilitating efficient batch processing.

What customization options are available?

To meet diverse production requirements, the MIX SZ/SZV mixers offer a range of optional features. These include temperature monitoring, load cells, water dosing systems, heating or cooling jackets, fully sealed covers, and Easy Clean systems. Each option can be tailored to your specific production needs, ensuring optimal performance and flexibility.

How do I clean and maintain the mixer?

The MIX SZ/SZV mixers are constructed entirely from stainless steel, providing durability and ease of cleaning. The design incorporates smooth surfaces and optional Easy Clean systems with tool-free access, supporting fast and thorough sanitation. This minimizes maintenance time and helps maintain the highest standards of hygiene in your production environment.