Series MA

Classic Vacuum Tumblers

Drum Volume

500-10,000

Liters

Max Tumbling Capacity

550 - 11,000

Lbs

- Precise Variable Control: Easily adjust all tumbling parameters, including vacuum level, rotation speed, tumbling time, and temperature. The machine is capable of operating at any setting within its full range, ensuring optimal performance for your specific needs.

- Continuous Vacuum Ability: Equipped with continuous vacuum capabilities to enhance product quality and consistency during processing.

Why Choose BAK

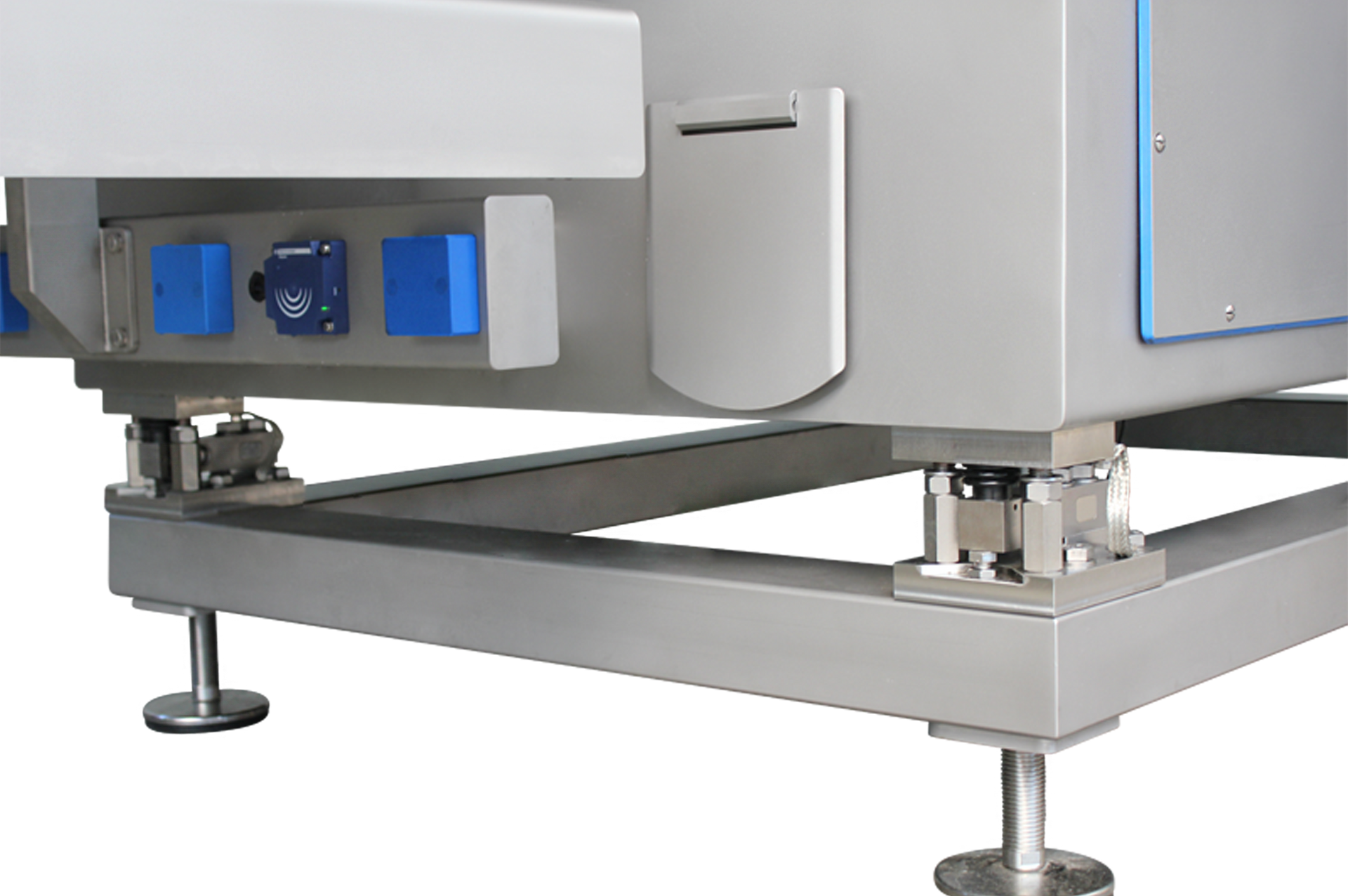

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 99 custom programs by adjusting variables such as vacuum level, rotation speed, tumbling time, and temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. Inspection hatches are strategically placed for quick, convenient access.

Technical Information

Applications

NOMA Classic Tumblers are designed for a wide range of applications, including red meat, pork, poultry, seafood, and plant-based products like fruits and vegetables. With precise control over protein extraction, marination, and tenderizing processes, they ensure consistent flavor distribution, improved texture, and enhanced moisture retention across various food types.

Poultry Processor

"Before our partnership with BAK, we faced an uphill battle juggling flavor quality, food safety, and efficiency. Their fully automated marination line transformed our processes to deliver a consistently superior product, all while reducing our labor demands. Six days a week, every single week, it just runs—like it’s part of our team.“ – Leadership team

You Might Also Like

More About Classic Vacuum Tumblers

What is a vacuum tumbler in food processing?

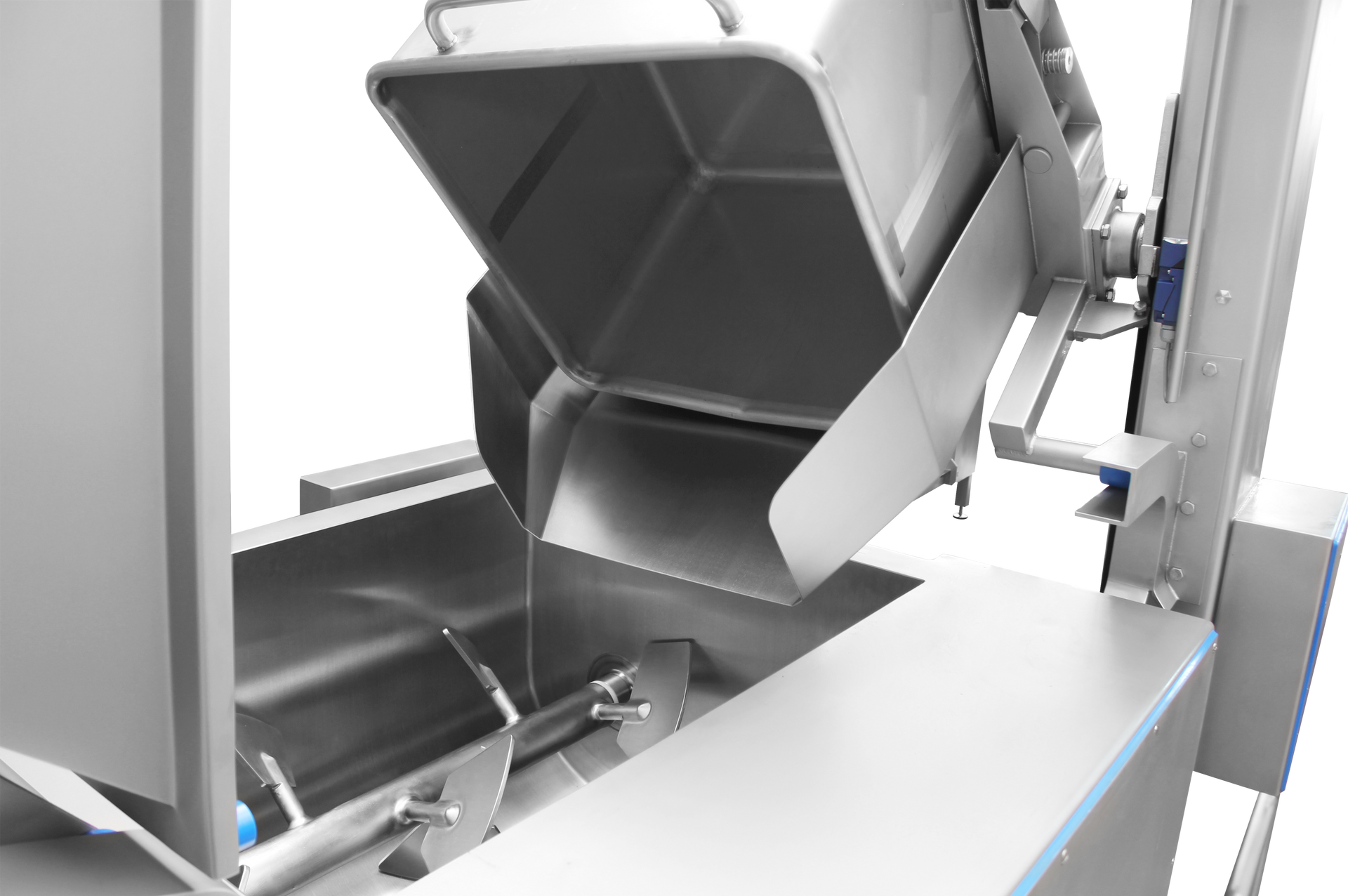

A vacuum tumbler is an industrial food-processing machine designed to enhance the quality and consistency of various protein products. These machines operate by rotating a drum containing the food product under a controlled vacuum environment. This process facilitates marination, protein extraction, and tenderizing, which improves flavor distribution, texture, and moisture retention.

What makes the Series MA Classic Vacuum Tumblers unique?

The Series MA Classic Vacuum Tumblers stand out due to their precise variable control and continuous vacuum capabilities. Operators can easily adjust tumbling parameters such as vacuum level, rotation speed, tumbling time, and temperature through an advanced programmable touch screen control panel that stores up to 99 custom programs. Constructed entirely from stainless steel, these machines offer exceptional durability and long-lasting performance in demanding industrial environments.

How do they improve product quality and consistency?

The Series MA Classic Vacuum Tumblers improve product quality and consistency by precisely controlling the tumbling environment to optimize marination, protein extraction, and tenderizing. The continuous vacuum feature reduces air pockets and promotes deeper marinade penetration, resulting in uniform flavor distribution and improved texture. The ability to save custom programs allows processors to tailor the process to specific product requirements, ensuring consistent results batch after batch.

Key Benefits of Using Vacuum Tumblers

How do vacuum tumblers enhance marination and flavor distribution?

The vacuum reduces air pockets within the product, enabling the marinade to be absorbed deeply and consistently throughout each batch. BAK Food Equipment's Classic Vacuum Tumblers offer precise variable control over vacuum level, rotation speed, tumbling time, and temperature, ensuring optimal marination tailored to specific product requirements. This results in enhanced flavor profiles and consistent texture across all processed batches.

How do vacuum tumblers improve tenderness and moisture retention?

Vacuum tumblers enhance tenderness by massaging the product which breaks down the muscle fiber creating a more tender product. Additionally, the vacuum environment and the tumbling process extracts protein which helps retain moisture by minimizing oxidation and preventing moisture loss during processing. This moisture retention is critical for maintaining a juicy flavorful product and improving yield.

What industries benefit from vacuum tumblers?

A wide range of industries benefit from vacuum tumblers, including red meat, pork, poultry, seafood, and plant-based food producers. BAK Food Equipment’s tumblers cater to operations of all sizes, with drum volumes ranging from 500 to 10,000 liters and tumbling capacities from 551 to over 11,000 pounds. This size range allows small-scale processors and large industrial producers alike to achieve consistent marination, tenderizing, and moisture retention.

Why Choose BAK’s Series MA Classic Vacuum Tumblers

What sets Series MA apart from other tumblers on the market?

BAK’s Series MA Classic Vacuum Tumblers distinguish themselves through their durable, industrial-grade, stainless steel construction and advanced control capabilities. The advanced programmable control panel with an intuitive touch screen allows operators to create and store up to 99 custom programs, adjusting variables such as vacuum level, rotation speed, tumbling time, and optional temperature control. With optional temperature control, products can be heated, cooled, defrosted, and cooked depending on the product and production requirements. This precise variable control ensures optimal performance tailored to specific product needs.

How do they support long-term efficiency and durability?

The stainless steel construction of the Series MA tumblers ensures long-term durability, hygiene, and compliance with stringent food safety standards. Stainless steel is resistant to corrosion and wear, which is critical in high-demand food processing environments. Designed with easy cleaning in mind, this not only reduces downtime but also helps maintain hygiene standards, which is vital for food safety compliance.

Why are they trusted worldwide in food processing plants?

Series MA Classic Vacuum Tumblers have proven performance in handling a wide range of applications—including red meat, pork, poultry, seafood, and plant-based products—demonstrates their versatility and effectiveness. The combination of durable food machinery construction, precise control features, and ease of maintenance makes them a preferred choice in high-demand environments.

FAQs About Classic Vacuum Tumblers

What is a vacuum tumbler in food processing?

A vacuum tumbler is an industrial food-processing machine designed to enhance the quality and consistency of various protein products. These machines operate by rotating a drum containing the food product under a controlled vacuum environment. This process facilitates marination, protein extraction, and tenderizing, which improves flavor distribution, texture, and moisture retention.

What makes the Series MA Classic Vacuum Tumblers unique?

The Series MA line offers drum capacities from 500 to 10,000 liters, advanced programmable controls with up to 99 saved programs, and continuous vacuum capabilities. They are built entirely from stainless steel for long-lasting performance in demanding food production environments.

What types of food can be processed with Series MA Vacuum Tumblers?

They are ideal for processing red meat, pork, poultry, seafood, and plant-based foods such as fruits, vegetables, and alternative proteins. This flexibility makes them valuable across multiple food processing sectors.

How do they improve product quality and consistency?

By precisely controlling the tumbling environment, it optimizes marination, protein extraction, and tenderizing. The continuous vacuum feature reduces air pockets and promotes deeper marinade penetration, resulting in uniform flavor distribution and improved texture.

Are Series MA Classic Vacuum Tumblers easy to clean?

Yes, these tumblers are thoughtfully designed for easy cleaning and maintenance. They feature strategically placed inspection hatches and smooth stainless steel surfaces that comply with food safety standards.

Can the Series MA Vacuum Tumblers be customized?

The Series MA tumblers offer several customization options to meet specific processing needs. These include jacketed cooling or heating systems to control product temperature, SCADA monitoring systems for enhanced process control, load cells for precise weight measurement, and automated loading systems to improve operational efficiency.

What industries typically use vacuum tumblers?

Vacuum tumblers are widely used in meat, poultry, seafood, and plant-based protein industries.

How does the programmable control panel help operators?

The advanced programmable control panel provides operators with precise control over all critical tumbling parameters, including vacuum level, drum speed, tumbling time, and temperature. It also allows for the creation and storage of up to 99 custom programs. This capability ensures repeatable and consistent processing results, reducing variability and improving product quality.