Series MIX/MIX V

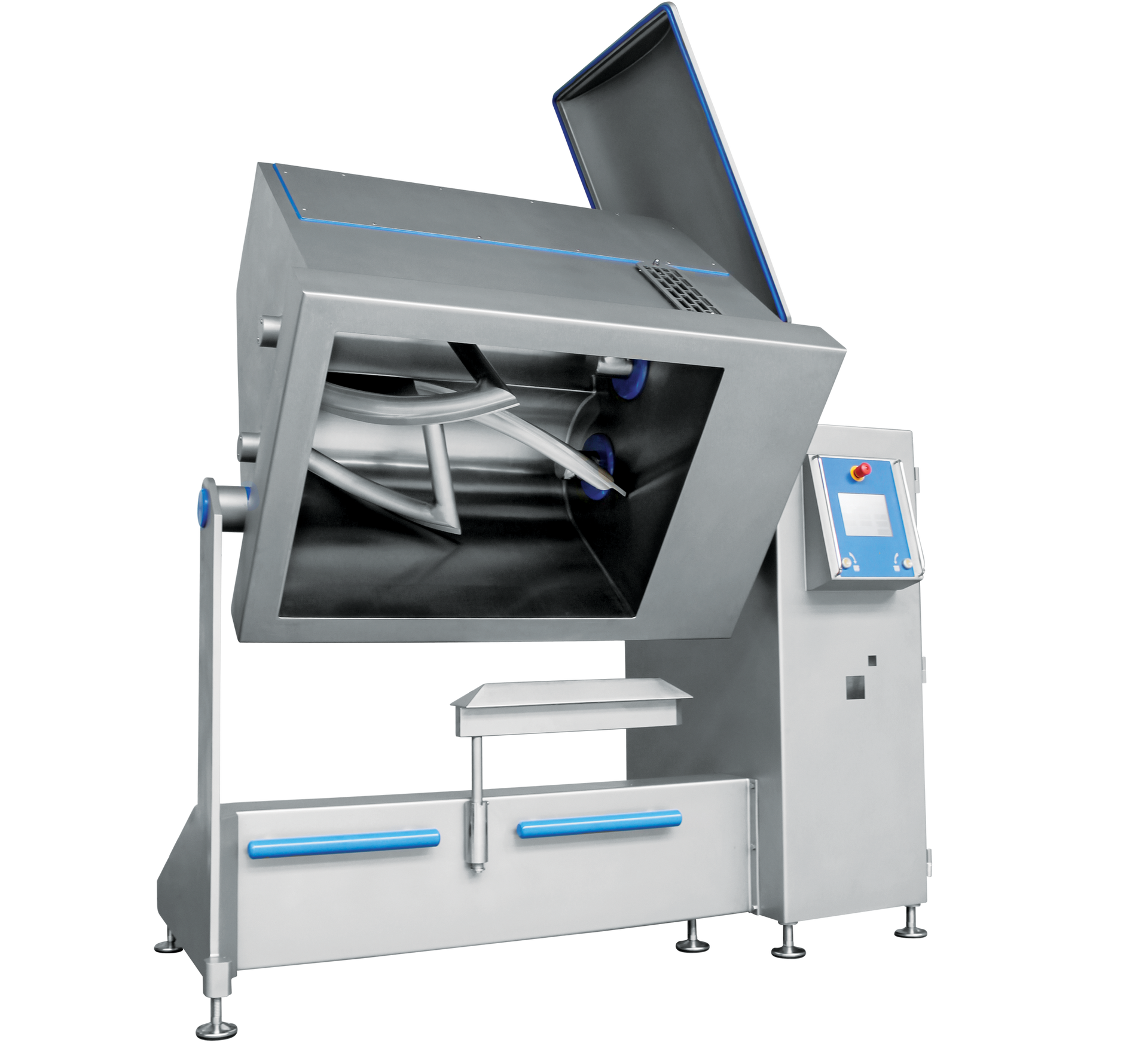

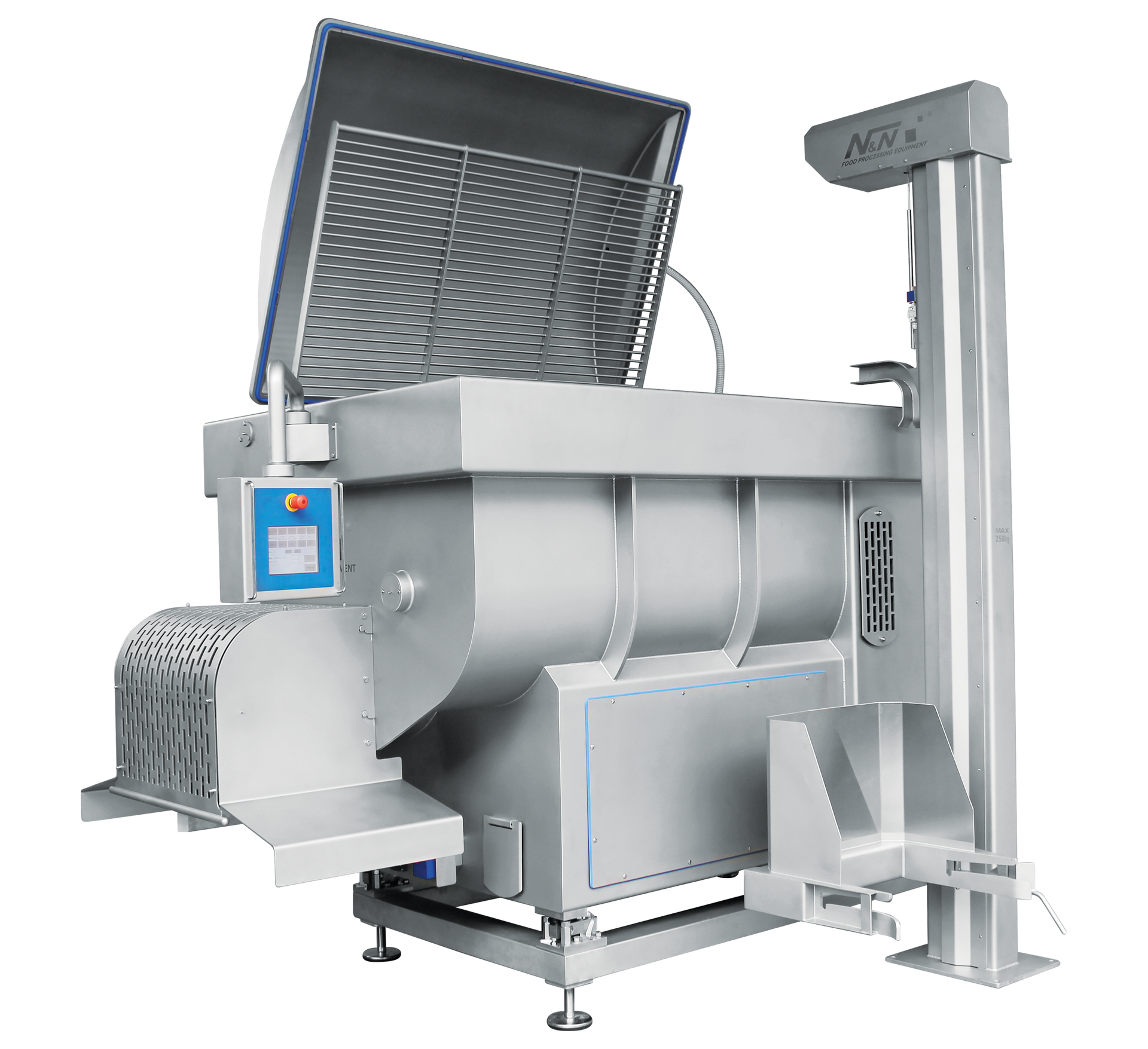

Industrial Intermeshing Paddle Mixers

Bowl Volume

180-8,000

Liters

Max Mixing Capacity

300-13,250

Lbs

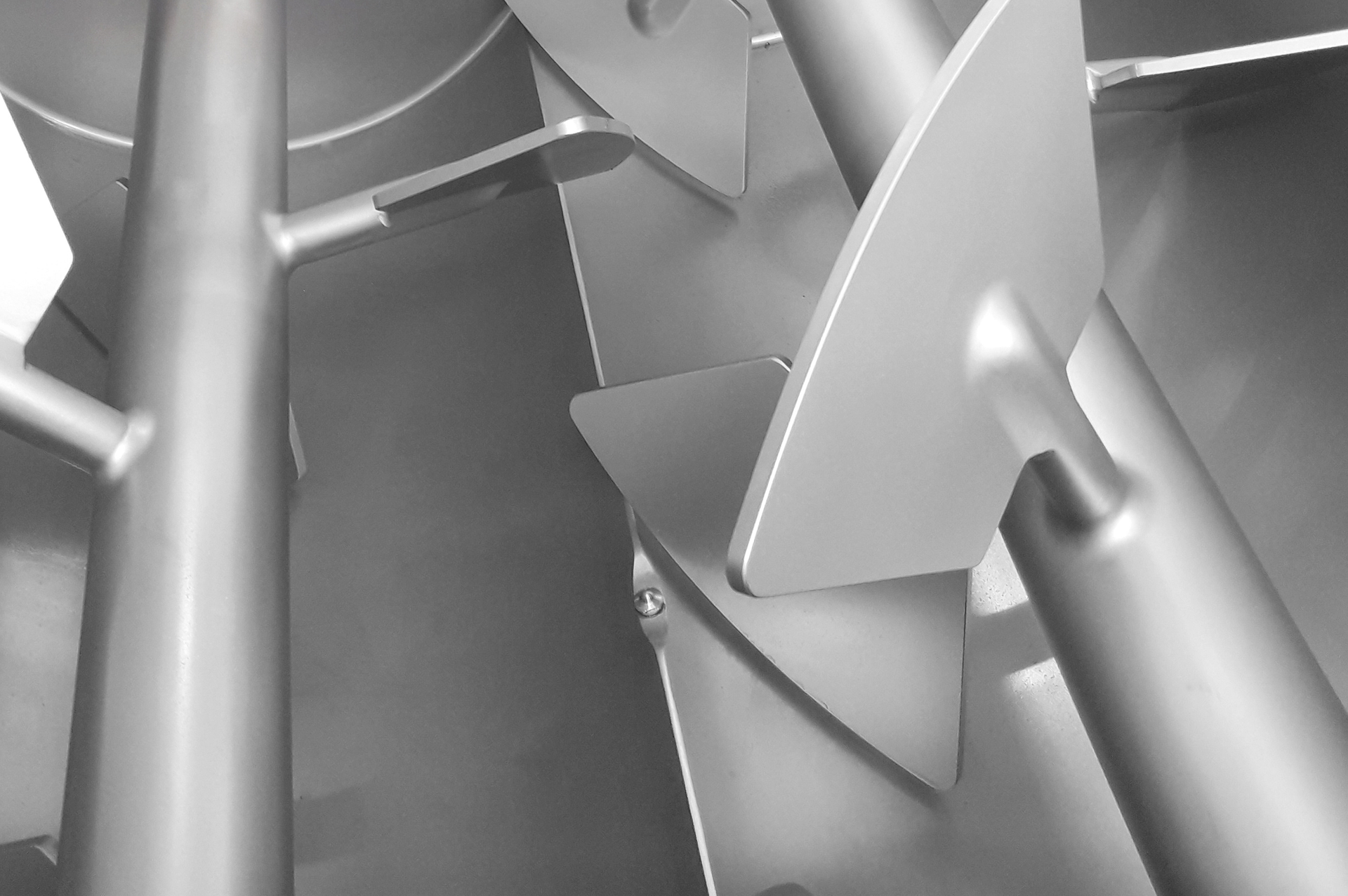

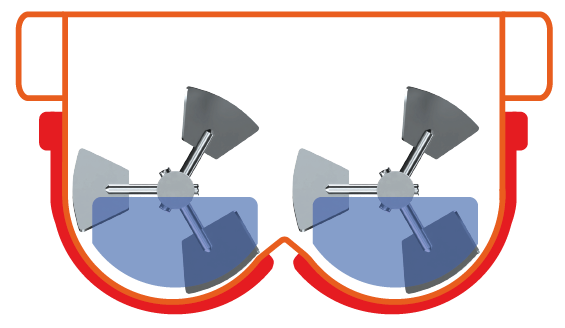

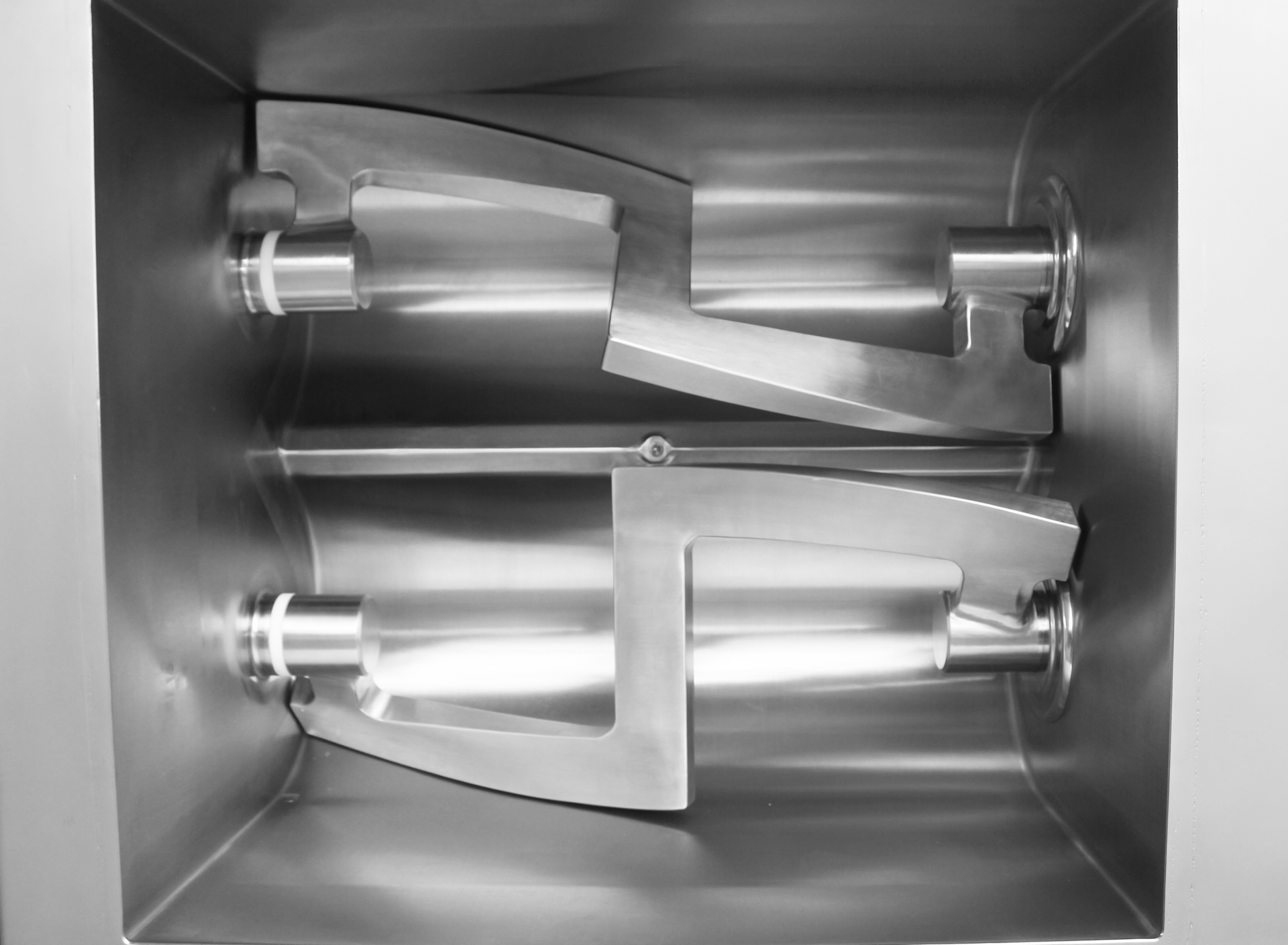

- Intermeshing Paddles: Features dual intermeshing paddle shafts at different heights that rotate in opposite directions, ensuring consistent and thorough mixing.

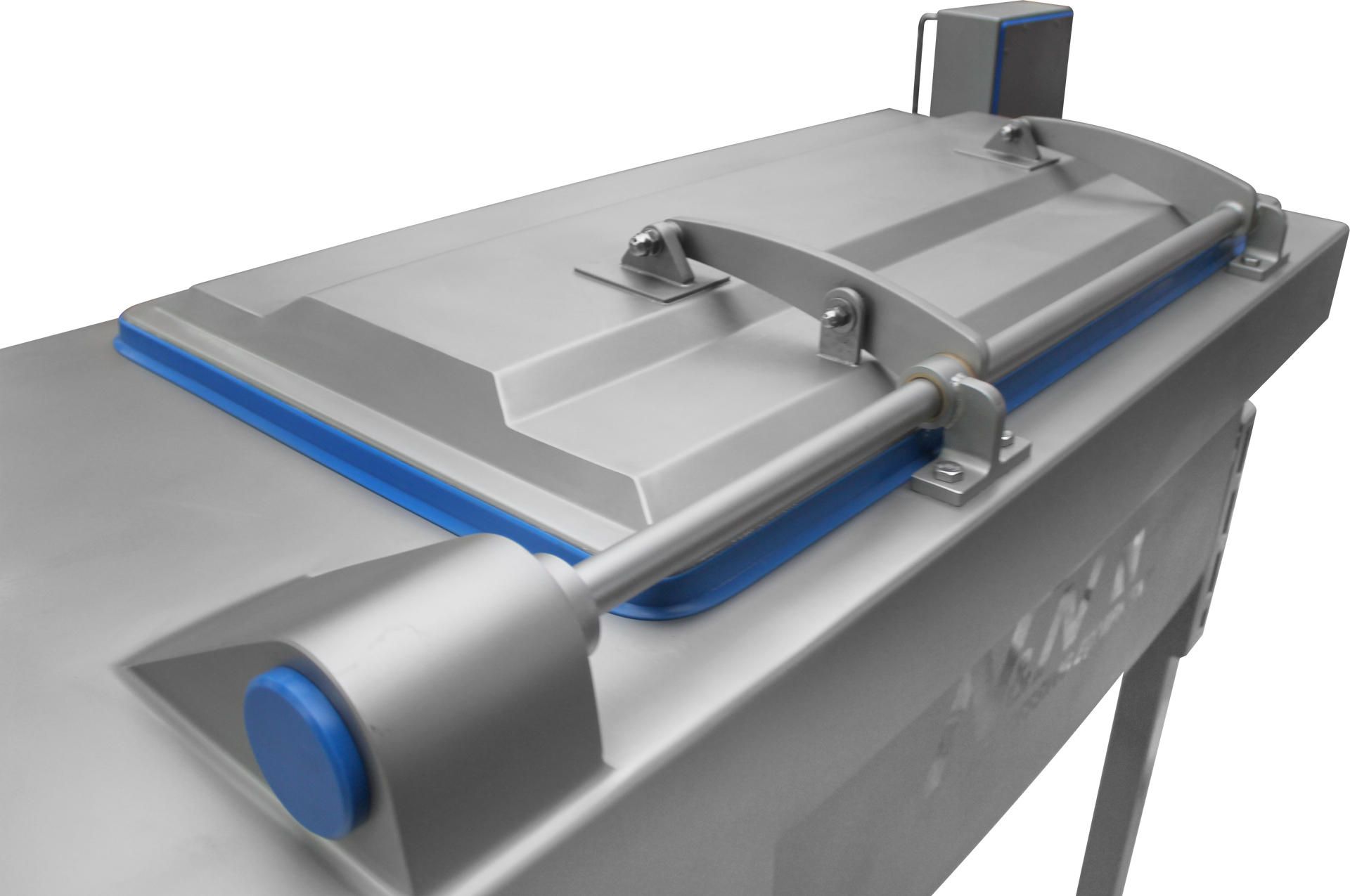

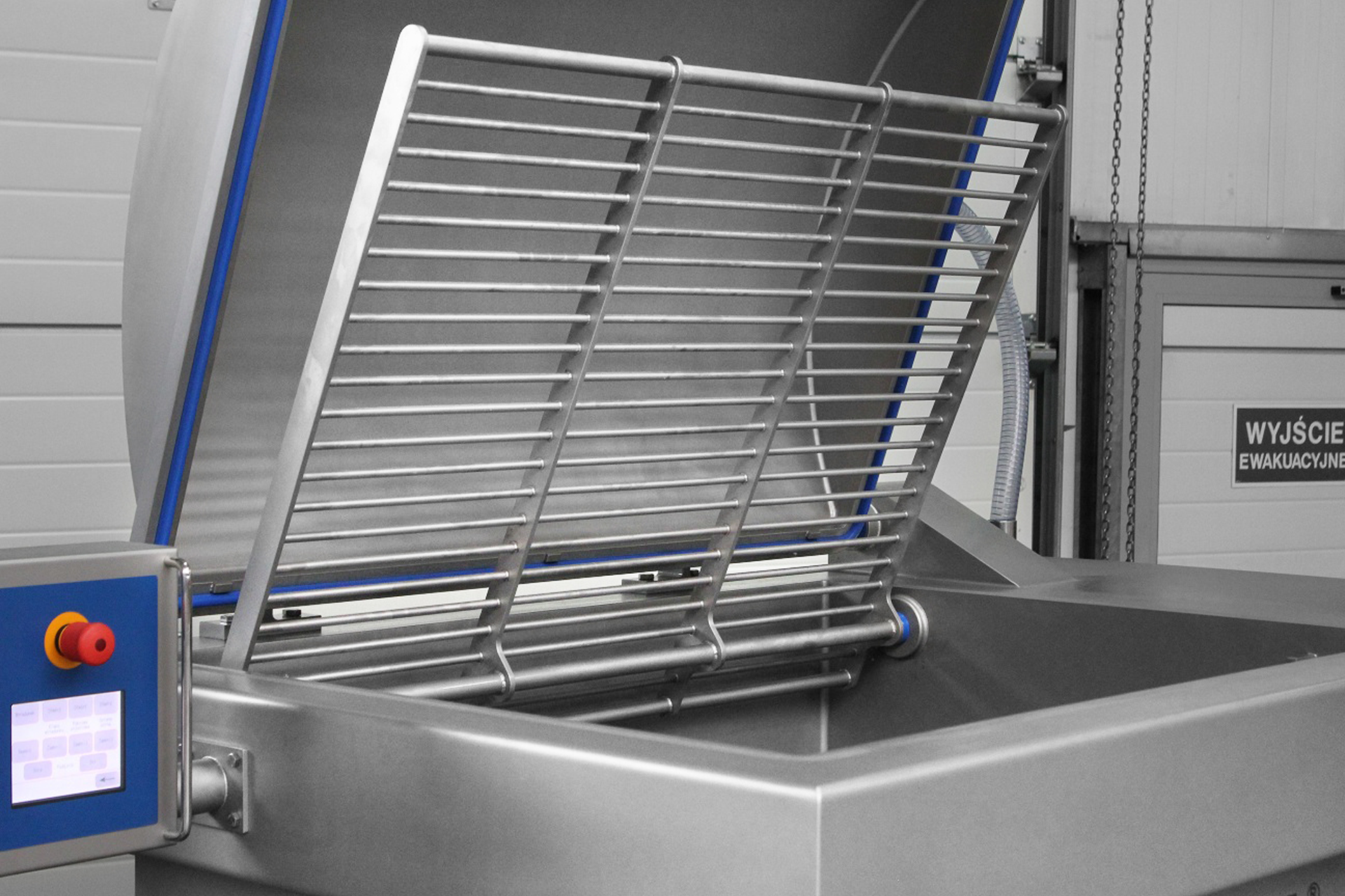

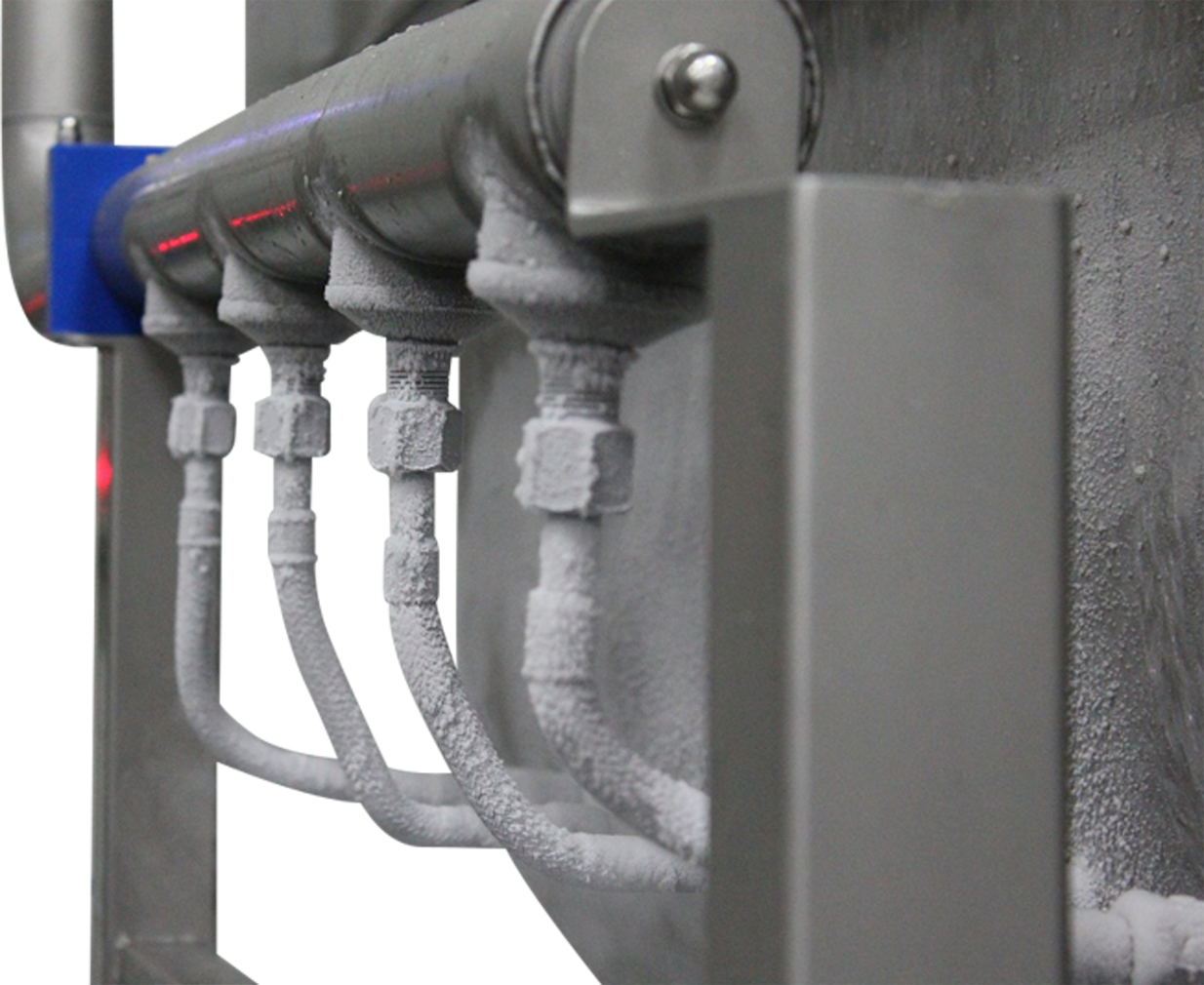

- Vacuum Option: Equipped with a reinforced bowl and airtight top cover, allowing up to 99% vacuum, which enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming.

- Variable speed: Offers precise speed adjustments, allowing the shafts to rotate at any desired speed within the machine's range.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

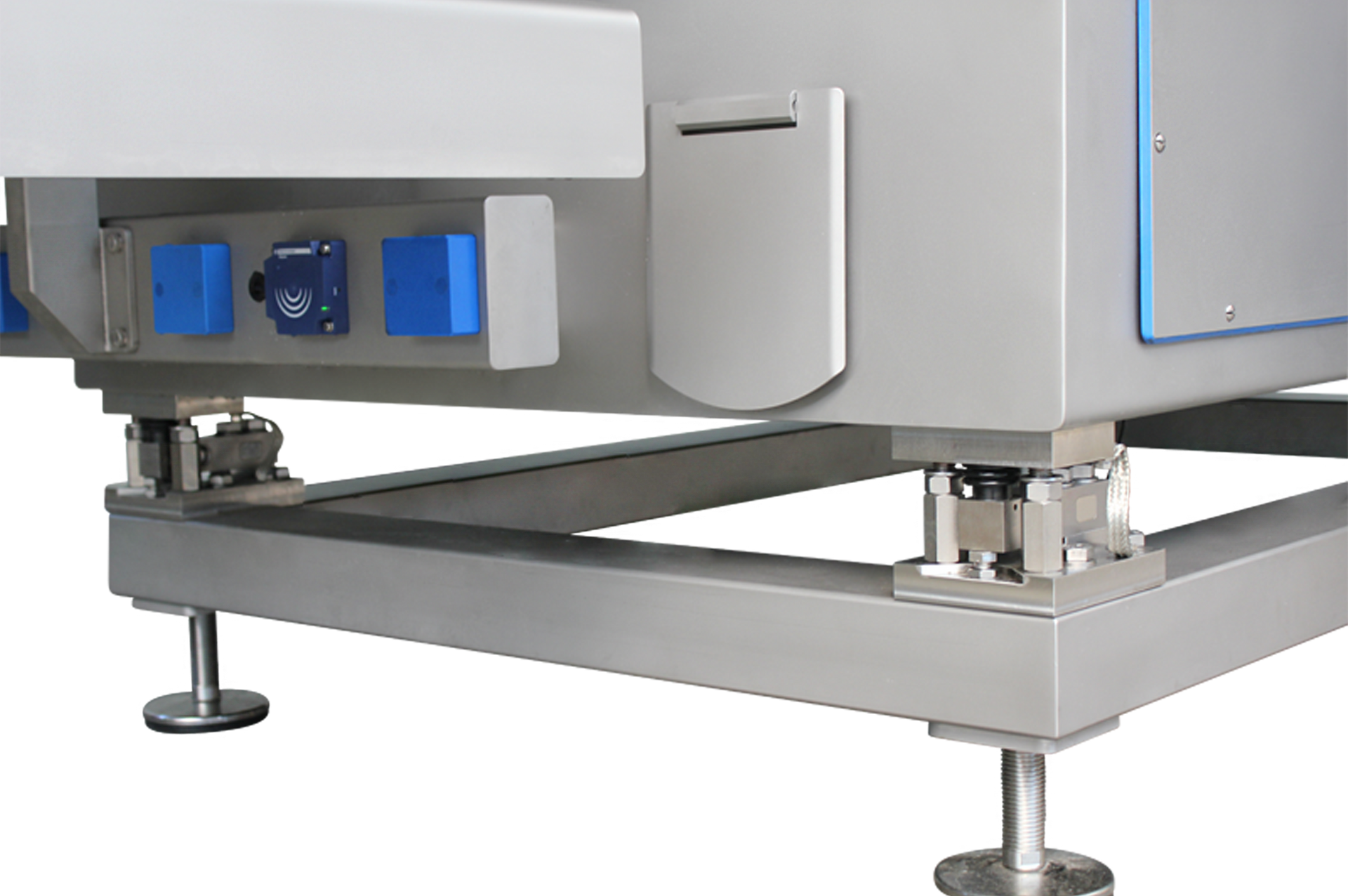

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as shaft rotation speed, shaft rotation direction, and vacuum level.

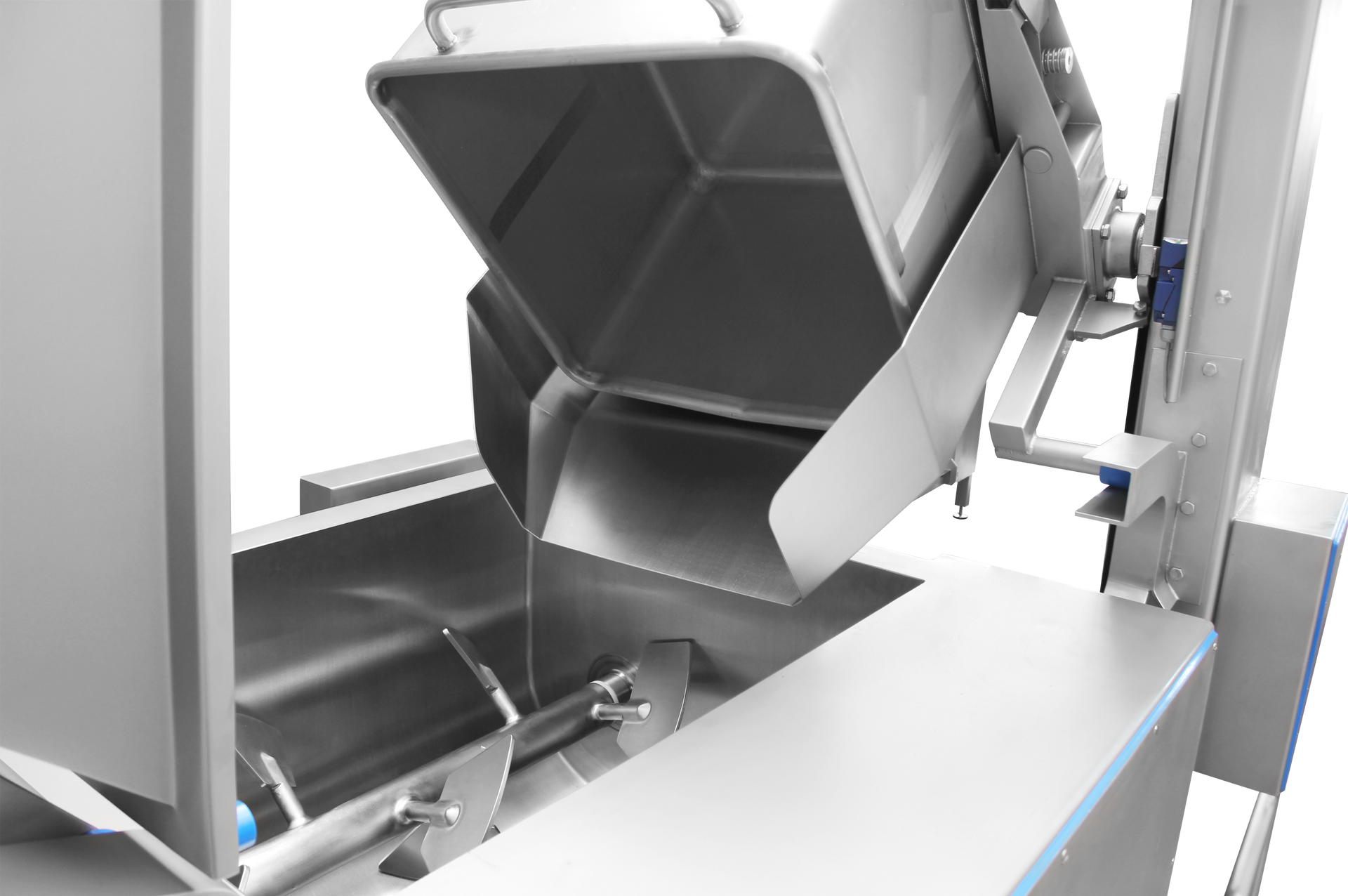

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient

Technical Information

Mix

Mix V

Applications

The MIX and MIX V series machines are some of the most versatile mixers available, designed to gently, efficiently, and quickly mix a wide variety of products. Whether it’s meat, poultry, fish, stuffings, vegetables, fruits, cereal mixes, dairy products, or even animal feed, these mixers handle it all, regardless of the product's viscosity or stickiness.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Paddle Mixers (MIX & MIX V Series)

What are paddle mixers and how do they work?

Paddle mixers are specialized industrial mixers designed to blend a wide range of food products efficiently and uniformly. They operate using dual intermeshing paddle shafts positioned at different heights that rotate in opposite directions. This unique configuration ensures thorough and consistent mixing by continuously moving and folding the product within the bowl. The paddles gently handle ingredients of varying viscosities and stickiness, making them ideal for delicate or complex mixtures.

What makes the MIX and MIX V paddle mixers unique?

The MIX and MIX V series from BAK Food Equipment stand out due to several advanced features. Both series incorporate intermeshing paddle shafts that provide superior mixing efficiency. A key differentiator is the vacuum option available in the MIX V series, which includes a reinforced bowl and airtight top cover capable of achieving up to 99% vacuum. This vacuum capability enhances protein extraction, improves liquid absorption, ensures even distribution of spices and additives, controls product density, and eliminates air bubbles prior to emulsification, filling, or forming processes. Additionally, these mixers offer variable speed control, allowing precise adjustment of shaft rotation speeds to suit specific product requirements. Constructed entirely from stainless steel, they provide durable, industrial-grade performance. The advanced programmable control panel with an intuitive touchscreen enables operators to create and store up to 100 custom mixing programs, adjusting variables such as speed, direction, and vacuum level. Furthermore, the design facilitates easy cleaning and maintenance, supporting hygienic food processing standards.

Which industries and products benefit from using paddle mixers?

The versatility of the MIX and MIX V paddle mixers makes them suitable for a broad spectrum of industries and products. They are widely used in meat, poultry, and fish processing for mixing ground meats and stuffing. The mixers also excel in handling vegetables, fruits, dairy products, cereals, and animal feed. Their ability to manage products regardless of viscosity or stickiness ensures consistent quality across diverse food processing applications. This adaptability positions them as essential equipment within industrial mixers and food processing equipment sectors, particularly where mixing efficiency and product integrity are critical.

Key Features of Industrial Paddle Mixers

What are the technical capabilities of these mixers?

Industrial paddle mixers from BAK Food Equipment feature dual intermeshing paddle shafts positioned at different heights that rotate in opposite directions. This design ensures thorough and consistent mixing across a wide range of product viscosities and stickiness, from meat and poultry to vegetables and dairy products. The mixers accommodate bowl volumes ranging from 180 to 8,000 liters and maximum mixing capacities from 300 to over 13,000 pounds, making them suitable for various production scales. Variable shaft speed control allows precise adjustment within the machine's range, enhancing mixing flexibility. Constructed entirely from stainless steel, these mixers offer industrial durability and are designed for easy cleaning and maintenance, supporting hygienic food processing environments.

How does the vacuum option improve results?

The vacuum option, available on the MIX V series, enhances mixing performance by creating up to 99% vacuum within a reinforced bowl and airtight top cover. This vacuum mixing capability significantly improves protein extraction, liquid absorption, and the distribution of spices and additives. It also controls product density and effectively eliminates air bubbles before subsequent processes such as emulsification, filling, or forming. By removing air, the vacuum option contributes to superior food quality, consistency, and shelf-life.

How does programmability enhance production?

BAK Food Equipment's paddle mixers are equipped with an advanced programmable control panel featuring an intuitive touch screen interface. Operators can create and store up to 100 custom mixing programs, adjusting variables such as shaft rotation speed, direction, and vacuum level. This automation in mixing streamlines production workflows, reduces human error, and ensures repeatable, high-quality results. Programmability also allows quick adaptation to different recipes and product requirements, increasing operational efficiency and flexibility in industrial food processing.

Technical Specifications Overview

What sizes and capacities are available?

BAK Food Equipment offers a comprehensive range of intermeshing paddle mixers in the MIX and MIX V series, designed to accommodate various production scales. The bowl volumes range from 180 liters to 8,000 liters, supporting mixing capacities from 300 pounds to over 13,000 pounds. This extensive size range ensures suitability for both small-batch and large-scale industrial production needs.

How do the MIX and MIX V differ?

The primary distinction between the MIX and MIX V models lies in the vacuum capability. The MIX series represents the standard intermeshing paddle mixers, while the MIX V series is equipped with vacuum functionality. MIX V machines feature a reinforced bowl and an airtight top cover, enabling up to 99% vacuum. This vacuum capability enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming. Both series share features such as dual intermeshing paddle shafts rotating in opposite directions for thorough mixing, variable speed control for precise shaft rotation, and durable stainless steel construction.

What industries can use small vs. large capacity models?

The versatility of the MIX and MIX V series makes them ideal for a wide array of industries within industrial food production. Smaller capacity models, such as those with bowl volumes between 180 and 650 liters, are well-suited for small-batch production, research and development, or specialty food manufacturing where precise control and flexibility are essential. Larger capacity models, ranging from 900 liters up to 8,000 liters, cater to high-volume production environments such as meat, poultry, fish processing, stuffing, vegetables, fruits, cereal mixes, dairy products, and even animal feed. This scalability in mixing equipment allows manufacturers to plan capacity effectively and optimize production lines according to their specific operational demands.

Industries That Rely on Paddle Mixers

Which industries use paddle mixers most frequently?

Paddle mixers are indispensable across a diverse range of industries due to their ability to provide consistent, thorough mixing of various products. In the food processing industries, they are widely used by meat, poultry, seafood, dairy, bakery, and ready-to-eat meal producers. These sectors depend on paddle mixers for uniform blending, marination, and ingredient distribution, ensuring product quality and consistency. Additionally, the pet food manufacturing and animal feed industries utilize paddle mixers to achieve uniform mixing of proteins, grains, vitamins, and additives, which is critical to meeting strict nutritional standards.

Beyond food, paddle mixers are essential in the pharmaceutical sector, where they handle powders, supplements, and functional blends requiring precise distribution of active ingredients. The chemical and agricultural industries also rely on paddle mixers for fertilizers, soil mixes, and specialty chemicals, where homogeneity is vital for product performance.

Why are paddle mixers essential for both food and non-food production sectors?

Paddle mixers offer versatility and efficiency that make them essential in both food and non-food production sectors. Their design, such as the intermeshing paddle shafts found in BAK Food Equipment's MIX and MIX V series, ensures consistent and thorough mixing regardless of product viscosity or stickiness.

Furthermore, paddle mixers equipped with vacuum options enhance processes by improving protein extraction, liquid absorption, and eliminating air bubbles before emulsification or forming. This feature is particularly beneficial in food processing industries to maintain product integrity and quality.

The durable, industrial-grade stainless steel construction of paddle mixers supports long-lasting performance in demanding environments, while advanced programmable control panels allow operators to customize mixing parameters for various applications. These attributes make paddle mixers a critical component in automated production lines across multiple sectors, including bakery equipment, dairy processing systems, pharmaceutical mixing, and agricultural mixing equipment.

Optional Add-Ons & Customizations

What options are available for customization?

BAK Food Equipment offers a comprehensive range of optional add-ons and customizations for their intermeshing paddle mixers to meet diverse production needs. These options include fully sealed covers that ensure airtight operation, openwork covers for flexible loading, and temperature monitoring systems to maintain precise control over the mixing environment. Cooling and heating jackets are available to regulate product temperature during processing, as well as liquid nitrogen or CO2 injection systems for cooling. Steam injections can also be used for heating or cooking. Additional features such as load cells provide accurate weight measurement, automated loaders facilitate seamless product transfer, and an easy-clean system simplifies maintenance. Polished bowls and shafts enhance hygiene and product quality, and water dosage systems enable precise water addition during mixing.

How do these add-ons improve performance?

These customizations significantly enhance efficiency, safety, and quality control of the mixing process. Fully sealed covers and vacuum options improve product consistency by eliminating air bubbles and enhancing ingredient absorption, which is critical for applications like protein extraction and spice distribution. Temperature monitoring and jacketed cooling/heating systems maintain optimal processing conditions, preventing overheating or chilling that could affect product integrity. Load cells and automated loaders streamline production workflows, reducing manual labor and minimizing errors. The easy-clean system and polished surfaces promote sanitary conditions, reducing downtime and contamination risks. Collectively, these add-ons support automation in food processing, enabling precise control and repeatability that are essential for high-quality food production.

Why Choose BAK Paddle Mixers?

What sets BAK Food Equipment apart in paddle mixing technology?

BAK Food Equipment distinguishes itself in paddle mixing technology through its commitment to durable, industrial-grade construction and advanced automation. The MIX and MIX V series intermeshing paddle mixers are built entirely from stainless steel, ensuring exceptional durability and long-lasting performance even in the most demanding food production environments. Moreover, BAK’s mixers incorporate an advanced programmable control panel with an intuitive touch screen interface. This allows operators to create and store up to 100 custom mixing programs, adjusting variables such as shaft rotation speed, direction, and vacuum level. This level of automation enhances productivity in mixing by enabling precise control and repeatability, reducing operator error and downtime.

Why should manufacturers choose the MIX/MIX V line?

Manufacturers should choose the MIX/MIX V line because these mixers combine proven durability with innovative features designed to optimize food processing operations. The availability of a vacuum option, which can achieve up to 99% vacuum, improves protein extraction, liquid absorption, spice and additive distribution, and density control while eliminating air bubbles before emulsification, filling, or forming. This capability is critical for producing high-quality, consistent products. Additionally, the MIX/MIX V series offers variable speed control, allowing precise adjustments to the shaft rotation speed within the machine’s range, which enhances flexibility for different product requirements. The mixers are also designed for easy cleaning and maintenance, a vital consideration for food manufacturers aiming to maintain hygiene standards and minimize downtime.

Intermeshing Paddle Mixer FAQs

What is the difference between the MIX and MIX V paddle mixers?

The MIX series consists of standard intermeshing paddle mixers featuring dual paddle shafts rotating in opposite directions at different heights to ensure consistent and thorough mixing. The MIX V series builds upon this design by incorporating a vacuum system capable of achieving up to 99% vacuum. This vacuum option enhances protein extraction, improves liquid absorption, eliminates air bubbles, and promotes more uniform distribution of spices and additives. These improvements result in a denser, more consistent mixture ideal for subsequent processes such as emulsification, filling, or forming.

What sizes of paddle mixers are available?

BAK Food Equipment offers the MIX and MIX V paddle mixers in a wide range of sizes to accommodate various production scales. Capacities range from 180 liters (approximately 298 pounds) up to 8,000 liters (around 13,250 pounds). This extensive size range ensures suitability for both small batch operations and large-scale industrial food processing.

What products can be processed in a paddle mixer?

The MIX and MIX V paddle mixers are highly versatile and designed to handle a broad spectrum of products. These include meat, poultry, fish, vegetables, cereals, dairy products, fruits, stuffing, animal feed, and even pharmaceutical products. The mixers effectively process products regardless of their viscosity or stickiness, making them adaptable to diverse food and non-food processing applications.

How does the vacuum option improve mixing?

The vacuum feature in the MIX V series removes entrapped air bubbles from the mixture, which enhances protein extraction and increases liquid absorption. This process leads to improved density and uniformity in the final product. By eliminating air, the vacuum system also ensures better distribution of spices and additives, resulting in consistent product quality before further processing steps such as emulsification or forming.

Can paddle mixers be customized for specific applications?

Yes, BAK Food Equipment offers numerous customization options to tailor paddle mixers to specific production requirements. Available options include temperature monitoring systems, cooling and heating jackets, liquid injection systems (both top and bottom), load cells for precise weighing, fully sealed or openwork covers, and automated loading systems. These features enable precise control over the mixing process and integration into automated production lines.

How easy are these mixers to clean and maintain?

The paddle mixers are constructed entirely from stainless steel, ensuring durability and compliance with hygiene standards. The optional Easy Clean system simplifies routine cleaning and maintenance, making it fast and efficient. Thoughtful design considerations facilitate straightforward access to all components, helping maintain high sanitation levels essential in food processing environments.