Smoke Chambers and Related Equipment for Industrial Food Processing

Achieve consistent flavor, color, and texture with precision-controlled smoking chambers from BAK Food Equipment

Introduction to Smoke Chambers and Related Equipment

What is industrial smoking equipment?

Industrial smoke equipment is used in food processing to improve the flavor, color, and texture of food using natural or liquid smoke. Smoke chambers, or batch houses, are specialized enclosures designed for the controlled smoking of food products, most commonly used in the production of smoked meats, poultry, fish, and cheeses. For high-volume operations, spiral smoking systems automate the process through continuous conveyor-driven production, ensuring consistent quality and efficiency.

Why are they essential in large and small scale food processing?

Industrial smoke chambers—also called batch houses—are essential across all scales of food processing because they create a tightly controlled environment that delivers repeatable results. By holding precise temperature, humidity, airflow, and smoke density profiles, they help every batch meet exact flavor, color, and texture standards. This consistency supports higher throughput, lowers labor per pound through well-controlled cycles, and strengthens food safety by reducing contamination risk. Smaller and mid-sized operators benefit from the same control and hygiene advantages, but the impact is especially pronounced for large producers, where delivering a uniform product is a decisive competitive edge.

What types of smoke chambers and related equipment are available?

BAK Food Equipment offers a comprehensive range of smoke chambers and related equipment to meet the diverse needs of food processors. Available systems include spiral smoking, cooking, and chilling systems, which are ideal for high-volume, continuous production lines. Semi-continuous smoke houses provide flexibility for medium-scale operations, while batch smoke houses are suited for smaller runs or specialty products. To support these chambers, BAK also supplies both natural and liquid smoke generators, allowing processors to choose the smoke application method that best fits their product and process requirements. Additionally, smoke trolley washers are available to ensure hygiene and operational efficiency throughout the production cycle. These solutions are designed to work in tandem with industrial smokehouses and food smoking equipment setups, supporting the demands of modern smoked meat processing.

Spiral Smoking, Cooking, and Chilling Systems

How do spiral smoking systems work?

Spiral smoking systems utilize a continuous conveyor belt that moves products through the spiral chambers. This automated movement eliminates the need for manual hanging or transport, streamlining the process which in turn reduces product inconsistencies and minimizes labor requirements. As products travel through the spiral, they are exposed to precisely controlled smoke, heat, and humidity, ensuring uniform flavor, color, and texture. The spiral design maximizes chamber space, allowing for high-capacity processing while maintaining consistent product quality.

What products are best suited for spiral systems?

Spiral smoke systems are ideal for high-volume, large-format products that benefit from consistent processing and minimal manual handling. Common applications include bacon, salmon, ribs, and other large-scale smoked meats. The system’s design supports products that are typically processed in bulk, making it especially valuable for industrial food processors seeking to maximize output and maintain product uniformity.

What advantages do spiral systems offer over batch smokehouses?

Compared to traditional batch smokehouses, spiral systems offer several key advantages. First, the automated conveyor movement reduces labor costs and eliminates the need for manual product handling. Second, spiral systems can process over 10,000 pounds of bacon per hour, making them ideal for high-capacity operations. Third, the continuous movement and controlled environment ensure consistent smoke exposure, resulting in improved yield and uniform product quality. These benefits make spiral smoke systems a preferred choice for processors looking to scale up production while maintaining high standards of efficiency and consistency.

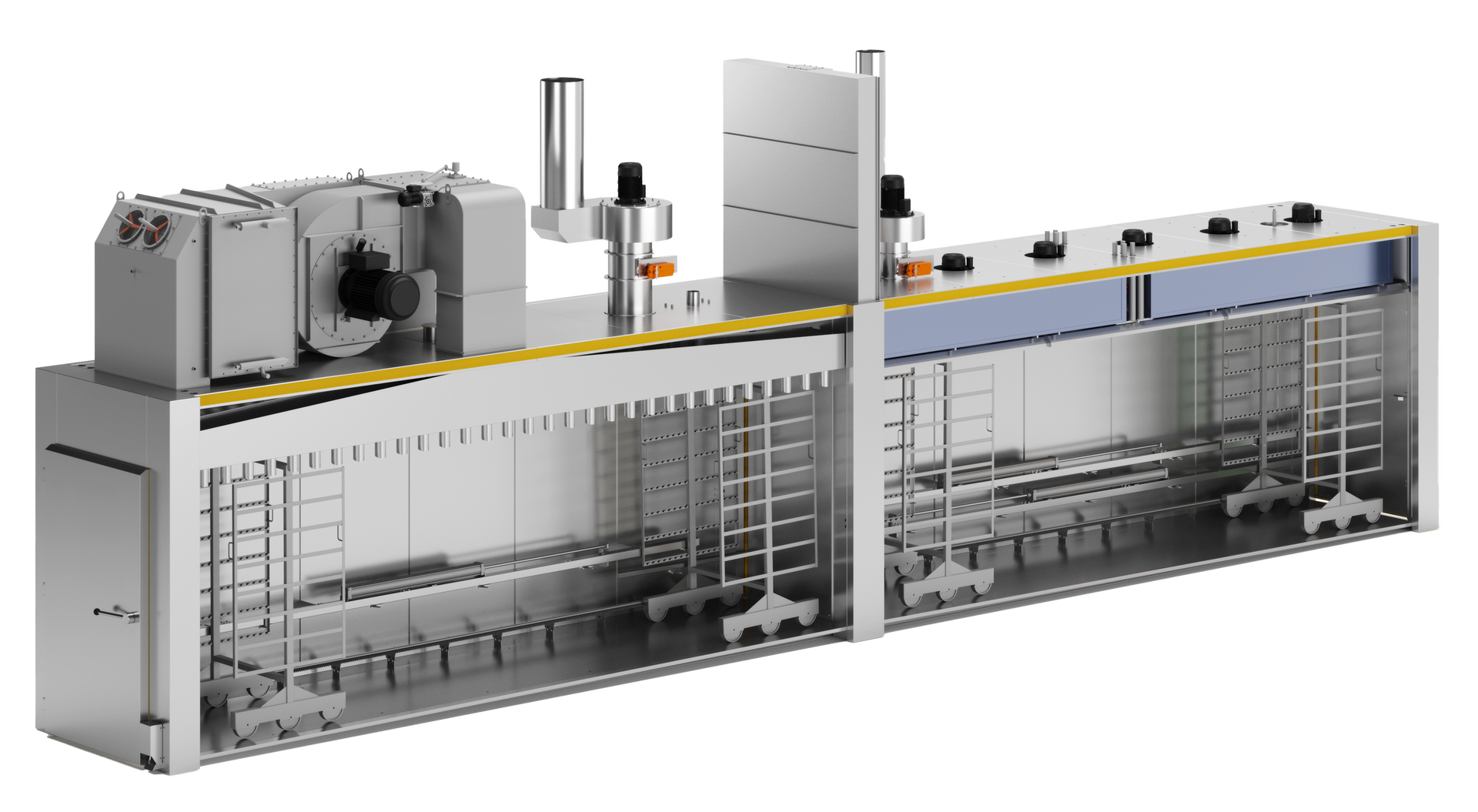

Semi-Continuous Smokehouses

What makes semi-continuous smokehouses different from batch systems?

Semi-continuous smokehouses stand apart from traditional batch systems through their ability to integrate multiple processing steps—smoking, chilling, and product transport—into a streamlined, semi-automated workflow. Unlike batch smokehouses, which require manual loading and unloading for each cycle, semi-continuous systems utilize automatic rail transport to move products seamlessly through each stage. This not only reduces labor requirements but also minimizes downtime between cycles, resulting in higher throughput and more consistent product quality. The alternating flap system within these smokehouses ensures even air circulation, which is critical for achieving uniform flavor, color, and texture across all products. Additionally, semi-continuous smokehouses offer flexibility in smoke application, supporting hot, cold, or hybrid smoking processes to accommodate a wide range of product requirements.

What production scale are semi-continuous smokehouses best suited for?

Semi-continuous smokehouses are ideally suited for medium to large-scale commercial operations that demand high efficiency and consistent results. Their design is optimized for facilities processing significant volumes of products, such as poultry, seafood, and red meats, where automation and integrated processing can deliver substantial productivity gains. The semi-continuous smoke chamber utilizes a tunnel smoking system configuration which is particularly advantageous for producers looking to scale up operations without sacrificing product quality or process control.

Batch Smokehouses

When should a producer choose a batch smokehouse?

Batch smokehouses are an ideal solution for food processors who require flexibility in their production processes. These systems are best suited for smaller or varied production runs, where the ability to switch between different products or recipes is essential. Producers who work with a diverse range of products—such as sausages, hams, poultry, or specialty meats—often benefit from the adaptability that batch smokehouses provide. The design of a batch smokehouse allows for precise control over smoking parameters, ensuring consistent flavor, color, and texture across different product types.

What flexibility do batch systems provide?

Batch smokehouses offer significant flexibility in both capacity and operation. With adjustable capacity ranging from 2 to 16 trolleys, processors can efficiently handle small test batches or scale up for larger orders without compromising product quality. These systems are equipped to handle both hot and cold smoke applications, making them suitable for a wide variety of meat smoking processes. Additionally, modern batch smokehouses from BAK Food Equipment feature remote monitoring and program storage capabilities, allowing operators to manage and replicate smoking programs with ease. This flexibility makes batch smokehouses a valuable asset for producers seeking a versatile, reliable, and efficient meat smoking solution.

Natural and Liquid Smoke Generators

How do smoke generators integrate with chambers?

Smoke generators are essential components of industrial smoking equipment, designed to seamlessly integrate with smoke chambers to deliver precise and consistent smoke application. At BAK Food Equipment, both natural woodchip smoke generators and liquid smoke systems are engineered to connect directly to the chamber’s airflow and control systems. This integration allows for automated production lines where smoke density, timing, and temperature are managed through advanced PLC controls. The result is a highly scalable solution that can be tailored to match the size and throughput of any smoke chamber, whether it’s a batch, semi-continuous, or spiral system. Safety is also a priority, with features such as fire suppression systems and real-time monitoring to ensure safe operation during continuous production.

What are the differences between natural woodchip vs. liquid smoke?

The choice between a woodchip smoke generator and a liquid smoke system depends on the desired flavor profile, operational efficiency, and product requirements. Natural woodchip or sawdust smoke generators produce traditional smoke by burning or smoldering hardwood chips, imparting a classic, robust flavor and aroma to products like meat, fish, and cheese. This method allows for nuanced flavor control based on wood type and combustion parameters. In contrast, liquid smoke systems atomize or spray purified smoke condensate into the chamber, offering a cleaner process with less residue and easier maintenance. Liquid smoke provides consistent flavor and color, and is ideal for processors seeking efficiency and reduced emissions. Both systems are scalable and can be customized to match the chamber size and production needs, ensuring flexibility for a wide range of applications.

Smoke Trolley Washers

Why are trolley washers important in food production?

Trolley washers play a critical role in food production environments, particularly in facilities that utilize smoke chambers for processing products such as meats and seafood. These washers are designed to thoroughly clean and sanitize the trolleys that transport products in and out of smoke chambers, ensuring that any residue, contaminants, or bacteria are effectively removed. This is essential for maintaining high standards of food processing sanitation and for meeting regulatory compliance requirements. By automating the cleaning process, trolley washers help reduce the risk of cross-contamination and uphold the integrity of the final product.

How do automated trolley washers improve sanitation and efficiency?

Automated trolley washers, such as those offered by BAK Food Equipment, significantly enhance both sanitation and operational efficiency. These systems utilize advanced cleaning technologies, including steam pasteurization, to achieve a high level of hygiene. The automated process eliminates the need for manual scrubbing, which not only reduces labor costs but also ensures a consistent and thorough cleaning cycle every time. Efficient drying processes and water recirculation features further optimize resource use, minimizing water and energy consumption. In addition, automated trolley washers are designed to handle the rigorous demands of meat plants, bakeries, and seafood processors, making them a versatile solution for a wide range of food production applications. By integrating smoke chamber cleaning equipment into their operations, food processors can maintain compliance, improve productivity, and ensure the safety and quality of their products.

Benefits of BAK Food Equipment Smoke Chambers

How do BAK systems save money and improve yields?

BAK’s patent-pending automated spiral smoking system delivers outsized ROI at scale. In a recent customer case, the spiral line generated over $2M in annual labor savings by replacing manual rack handling with continuous, automated product movement that frees staff for higher-value work. It is estimated that processors have also realized #1 bacon yield gains worth $7–$11M per year, enabled by precise control of temperature, humidity, airflow, and smoke density that reduces trim, and giveaway. Hygienic, CIP-supportive zones shorten changeovers and sustain uptime, while the compact vertical design can cut required floor space by up to ~60% versus equivalent batch capacity. The spiral integrates cleanly with upstream and downstream equipment—from loading and chilling to slicing and packaging—supporting a continuous, high-throughput flow with consistent quality and food safety.

What sets BAK’s smoking systems apart from others?

BAK’s smoking systems stand out for their precise control, versatility, and hygienic design. Each unit is engineered with advanced PLC or microprocessor controls that regulate temperature, humidity, airflow, and smoke density to ensure consistent color, flavor, and texture across every batch. The systems support both traditional natural smoke and clean liquid smoke generation, giving processors flexibility to meet product and sustainability goals. Built from fully welded stainless steel with rounded corners and optional clean-in-place (CIP) systems, BAK smokehouses are easy to maintain and designed for superior hygiene. Optimized airflow and insulation reduce energy consumption and shorten smoking cycles, lowering overall operating costs. Available in both batch, and semi continuous, and fully continuous spiral configurations, BAK customizes each solution to fit specific product types, production volumes, and plant layouts—backed by expert installation, training, and ongoing technical support.