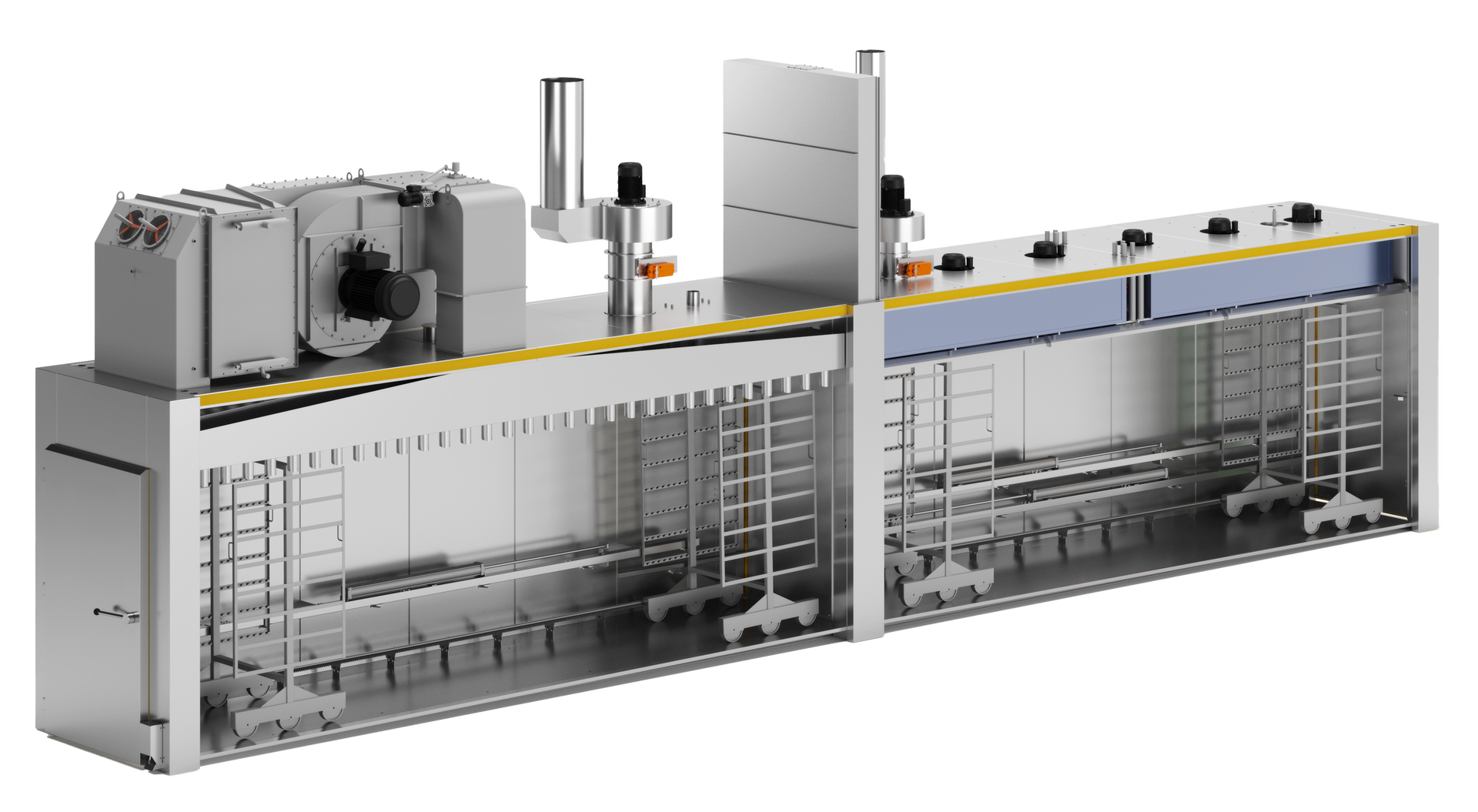

Smoke Trolley Washers

Size Ranges

2 to 4 Trolleys with screens in 15 minutes (8 to 16 Trolleys per hour)

- Movable Washing Nozzles: The washing nozzles are mounted on a rail system that travels back and forth inside the washer, ensuring thorough cleaning of the trolleys from multiple angles for optimal sanitation.

- Efficient Drying Process: The trolleys are heated to around 176°F using steam inside the chamber, allowing them to dry quickly and efficiently as they exit the washer without the need for additional drying equipment.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments

Integrated PLC Controls:

Intuitive touch screen allows operators to create and store custom programs.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

The Protech Trolley Washer is designed for efficient and thorough cleaning of trolleys and screens used in food processing environments. Ideal for meat processing plants, bakeries, and other industrial food production facilities, it provides automated washing, steam pasteurization, and minimal water consumption through its built-in recirculation system.

Large Bacon Producer

"Before we introduced BAK’s automated spiral system, our bacon production rose and fell with Monday’s workforce. Now that we’ve streamlined the entire process—smoking, cooking, and chilling in a single continuous system—we’ve not only stabilized our output, but we’re producing better bacon than ever. It’s been a complete game-changer.“ – Leadership team