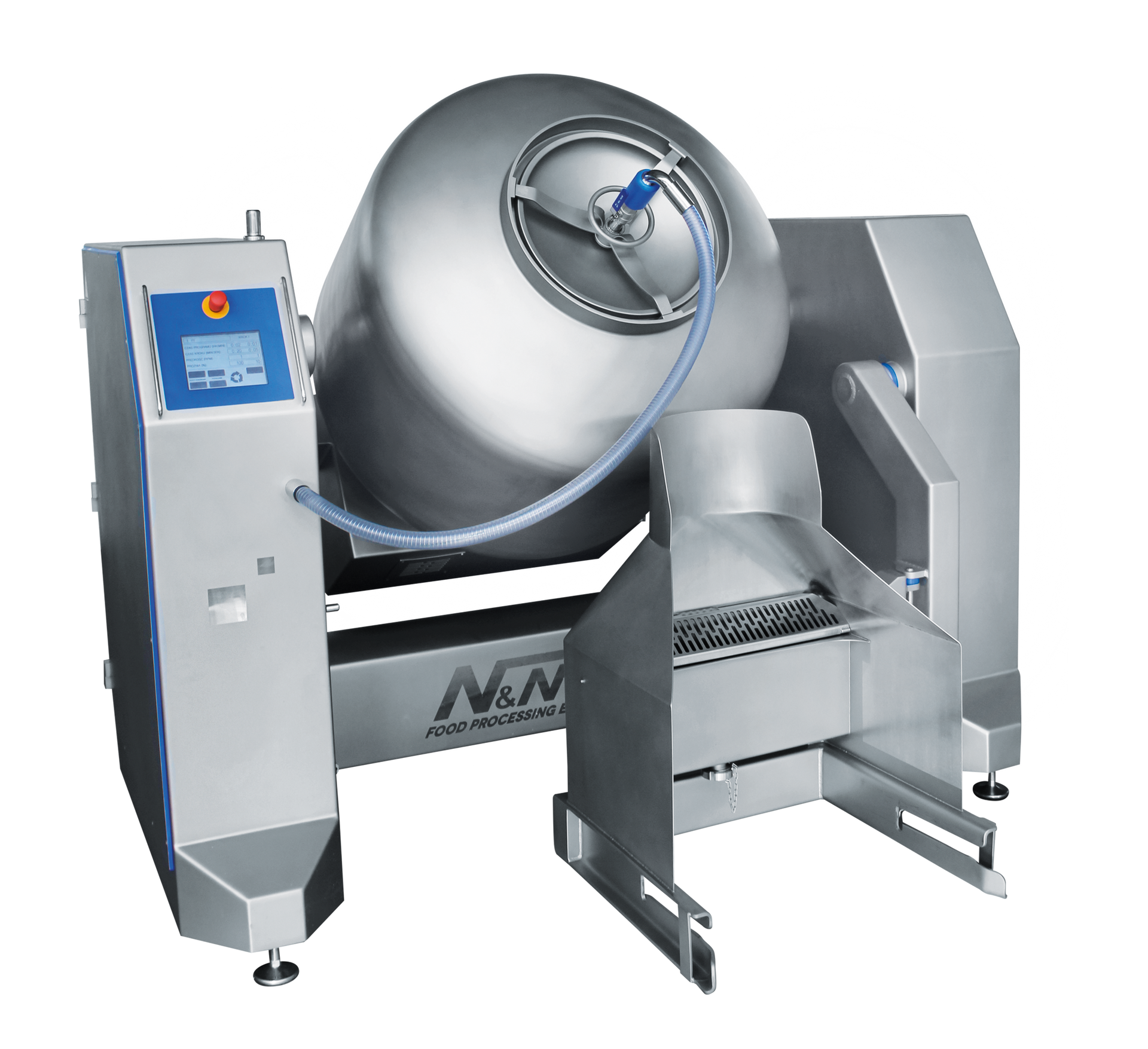

Series MV

Industrial Mixing Tilting Vacuum Tumblers

Drum Volume

300 - 1000

Liters

Max Tumbling Capacity

350 - 1300

Lbs

- Continuous vacuum ability: Equipped with continuous vacuum capabilities to enhance product quality and consistency during processing.

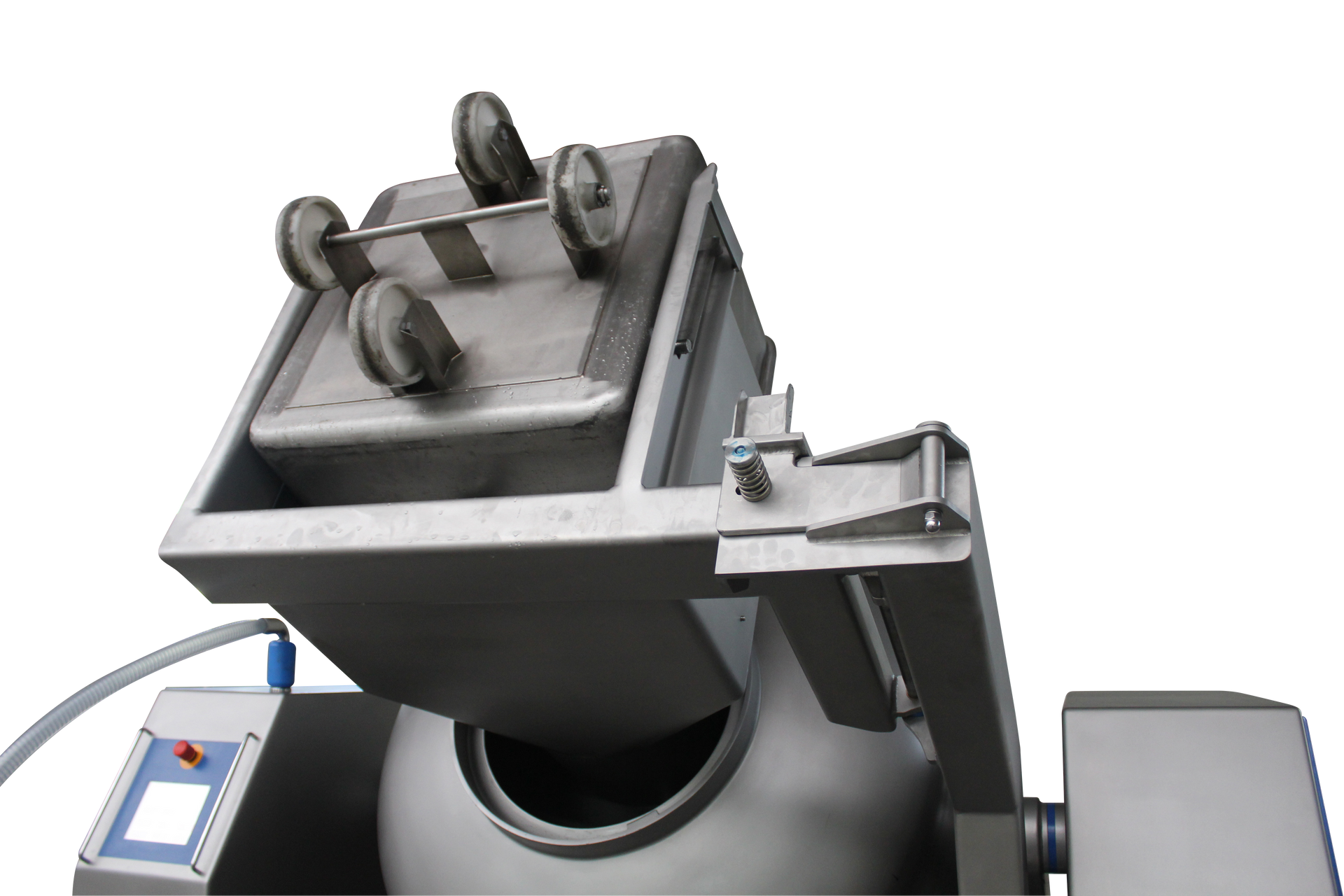

- Dual-Mode Tumbling System: Designed with asymmetrical fins to provide greater control. The system ensures gentle tumbling for delicate products by preventing product lifting when rotating left, while rotating right lifts the product for a more aggressive action, significantly reducing process time.

- Adjustable Drum Positioning: The N&N MV series vacuum tumblers feature a unique mechanical drum positioning system, allowing the drum to tilt up to 120 degrees for enhanced processing versatility.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as vacuum level, rotation speed, tumbling time, and temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. Inspection hatches are strategically placed for quick, convenient access.

Technical Information

Applications

N&N Mixing Tilting Tumblers are designed for a wide range of applications, including red meat, pork, poultry, seafood, and plant-based products like fruits, vegetables, and cereal mixes. With precise control over protein extraction, marination and tenderizing processes, they ensure consistent flavor distribution, improved texture, and enhanced moisture retention across various food types.

Poultry Processor

"Before our partnership with BAK, we faced an uphill battle juggling flavor quality, food safety, and efficiency. Their fully automated marination line transformed our processes to deliver a consistently superior product, all while reducing our labor demands. Six days a week, every single week, it just runs—like it’s part of our team.“ – Leadership team

You Might Also Like

Advanced Tumbling Technology for Consistent Results

What makes mixing tilting vacuum tumblers essential in modern food processing?

Mixing tilting vacuum tumblers have become indispensable in today’s food processing industry due to their ability to deliver consistent, high-quality results across a wide range of products. By combining gentle yet thorough motion with advanced vacuum technology, these machines optimize protein extraction, marination, tenderizing, and mixing efficiency. The vacuum environment enhances the absorption of marinades and seasonings, ensuring deep flavor penetration and improved moisture retention. This is particularly important for applications such as red meat, pork, poultry, seafood, and even plant-based products, where uniform flavor distribution and texture are critical. Additionally, the tilting feature allows for easy unloading and flexible processing, making these tumblers a versatile solution for processors seeking both quality and efficiency.

How does BAK’s Series MV design improve product quality and processing speed?

BAK’s Series MV mixing tilting vacuum tumblers are engineered to elevate both product quality and operational speed. The continuous vacuum system maintains optimal conditions throughout the process, maximizing protein extraction and marination effectiveness. The tumbling system, featuring asymmetrical fins, offers precise control: gentle tumbling for delicate products when rotating left, and a more aggressive action when rotating right, which significantly reduces processing time without compromising product integrity. The programmable control panel allows operators to fine-tune variables such as vacuum level, drum speed, tumbling duration, and temperature, and store up to 100 custom programs for repeatable, reliable results. The mechanical drum positioning system enables the drum to tilt up to 120 degrees, enhancing processing versatility and simplifying product discharge. Built entirely from stainless steel, the Series MV is designed for durability and easy maintenance, with strategically placed inspection hatches for quick access. These features collectively ensure that every batch achieves uniform flavor, texture, and moisture, meeting the highest standards of modern food processing.

By integrating advanced vacuum tumbling technology and programmable controls, BAK’s Series MV tumblers set a new benchmark for consistency, efficiency, and product quality in food marination and protein extraction.

Why Choose BAK Food Equipment

Why are BAK’s mixing and tilting vacuum tumblers trusted by processors worldwide?

BAK Food Equipment’s mixing and tilting vacuum tumblers are relied upon by food processors around the globe for their exceptional performance, versatility, and reliability. These machines are engineered for a wide range of applications, from red meat and poultry to seafood and plant-based products, ensuring consistent results in marination, protein extraction, and tenderizing. The advanced tumbling system, featuring asymmetrical fins, allows for both gentle and aggressive tumbling actions, reducing process times while maintaining product integrity. Continuous vacuum capabilities further enhance product quality and consistency, making these tumblers a preferred choice for processors seeking dependable, high-quality food processing machinery.

What value does BAK bring beyond the machine itself?

BAK Food Equipment is more than just a supplier of industrial vacuum tumblers; we are a long-term partner in efficient, scalable food production. Our team brings deep industry expertise and technical support to every project, ensuring seamless integration with automated production lines and the flexibility to configure equipment to your unique requirements. Whether you need custom drum volumes, specialized control panels, or integration with BAK automation systems, our solutions are tailored to fit your operation. Global service and support mean you can rely on BAK for ongoing maintenance, troubleshooting, and optimization, maximizing equipment reliability and uptime. With BAK, you gain a partner committed to food processing innovation and the long-term success of your business.

Food Mixing Tilting Tumblers FAQs

What is the purpose of a mixing and tilting vacuum tumbler?

Mixing and tilting vacuum tumblers are designed to enhance marination and protein extraction processes by combining vacuum pressure with rotational mixing. The vacuum environment allows for deeper and faster penetration of marinades and seasonings, while the rotating drum ensures even distribution throughout the product. This results in faster, more uniform marination, improved protein extraction, and consistent product quality. The MV series, for example, features continuous vacuum capabilities and asymmetrical fins, which can be gentle or aggressive depending on the product requirements, significantly reducing processing time and improving yield.

Can this equipment handle both meat and plant-based products?

Yes, mixing and tilting vacuum tumblers are engineered for versatility and can process a wide range of ingredients. They are suitable for red meat, pork, poultry, seafood, as well as plant-based products such as fruits, vegetables, and cereal mixes.

What’s the advantage of adjustable drum tilting?

Adjustable drum tilting provides operators with greater control over product movement within the tumbler. The N&N MV series allows the drum to tilt up to 120 degrees, which enhances processing versatility and tumbling intensity. This feature helps reduce processing time by ensuring that all product surfaces are exposed to the marinade or seasoning, and it improves consistency by preventing product clumping or uneven mixing. The ability to adjust the drum position also makes unloading and cleaning more efficient.

How do programmable controls improve efficiency?

Advanced programmable control panels, such as those found on the N&N MV series, allow operators to create and store up to 100 custom programs. Variables like vacuum level, rotation speed, tumbling time, and temperature can be precisely adjusted and saved for each product type. This automation reduces manual adjustments, ensures repeatable results, and improves overall yield. Operators can quickly switch between recipes, streamlining production and minimizing downtime.

Is the system easy to clean and maintain?

Absolutely. Mixing and tilting vacuum tumblers are constructed entirely from stainless steel, ensuring durability and ease of cleaning. The design includes strategically placed inspection hatches for quick and convenient access, making routine cleaning and maintenance straightforward. This not only helps maintain hygiene standards but also reduces downtime between batches. For additional peace of mind, BAK Food Equipment offers comprehensive warranty and service support to keep your equipment running smoothly.