Series LR

Rotary Label Remover

Efficiency

Up to 1100

Containers Per Hour

Max Container Size

23.6 x 15.7 x 7.9

inches (L,W,H)

- Rotating Turntable with Movable High-Pressure Nozzles: The system features a conveyor with a rotating turntable and high-pressure nozzles that move along the container. As the container rotates, the powerful water stream efficiently removes labels and label adhesive.

- Efficient Washing System: Designed to effectively remove labels and label adhesive on up to 1100 containers an hour accommodating any plastic container that fits within the specified dimensions for exceptional cleaning performance.

- Variable Control: Easily adjust variable washing parameters such as conveyer speed, rotation speed, water temperature, and intensity of rinsing.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs by adjusting variables such as conveyor speed and water temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

NOMA Label Removers are designed to remove labels, stickers and label adhesive from all sides of containers up to an efficiency of 1100 per hour. The machine is suitable for food processing as well as broader industrial and warehouse applications.

Snack Stick Case Study

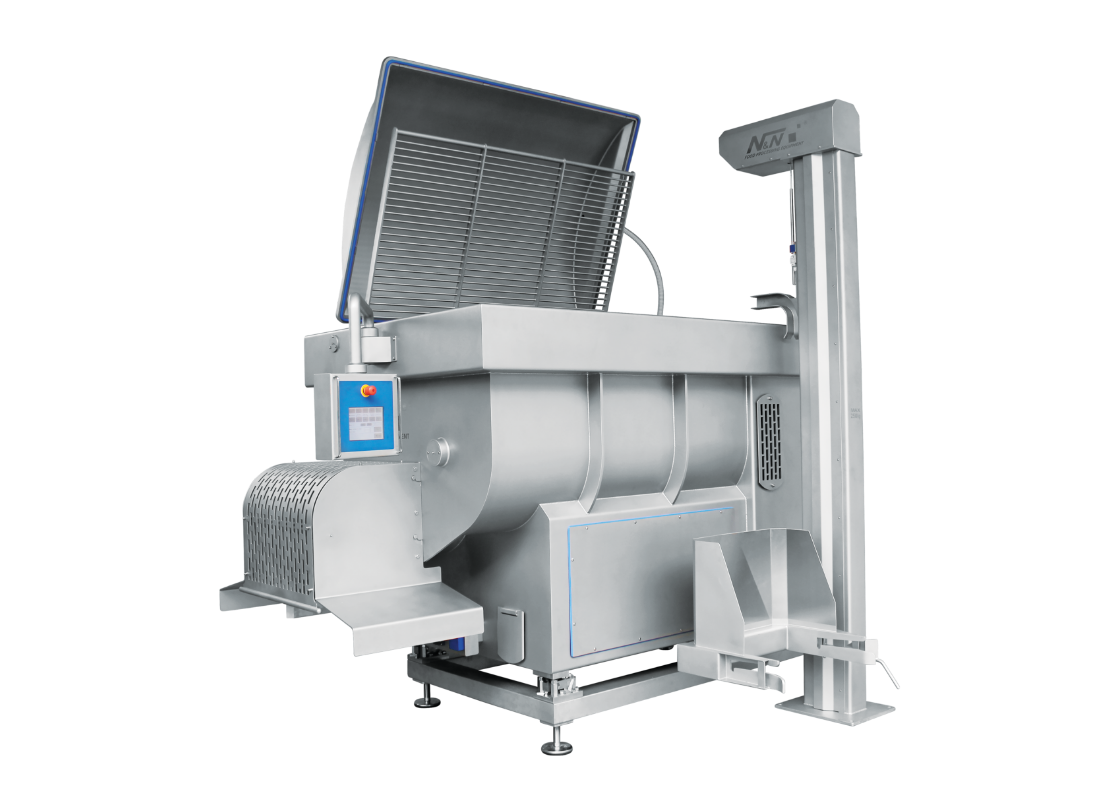

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team