Series KN

High-Speed Bowl Cutters & Choppers for Industrial Food Processing

Bowl Volume

60-750

Liters

Max Capacity

100 to 1325

Lbs

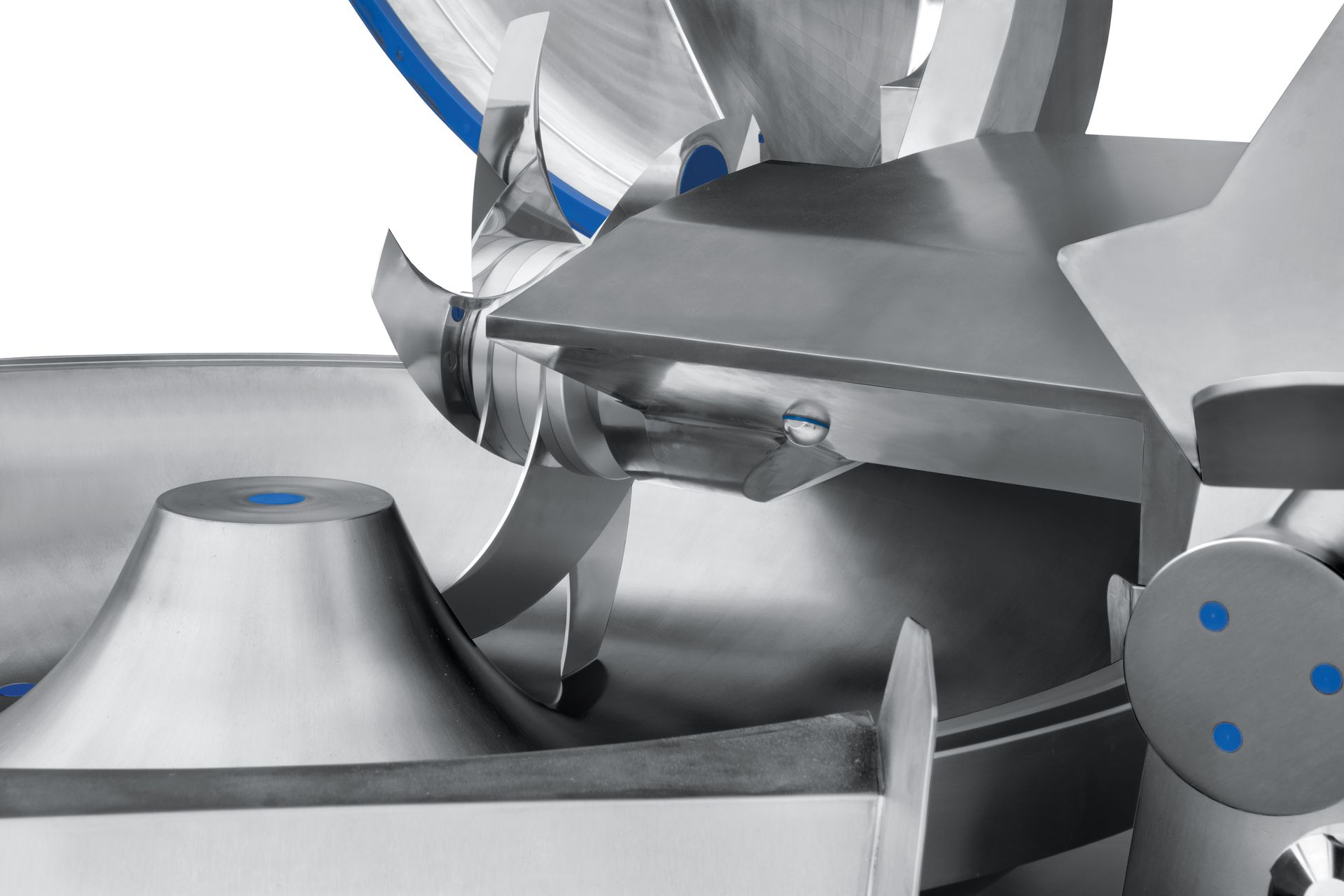

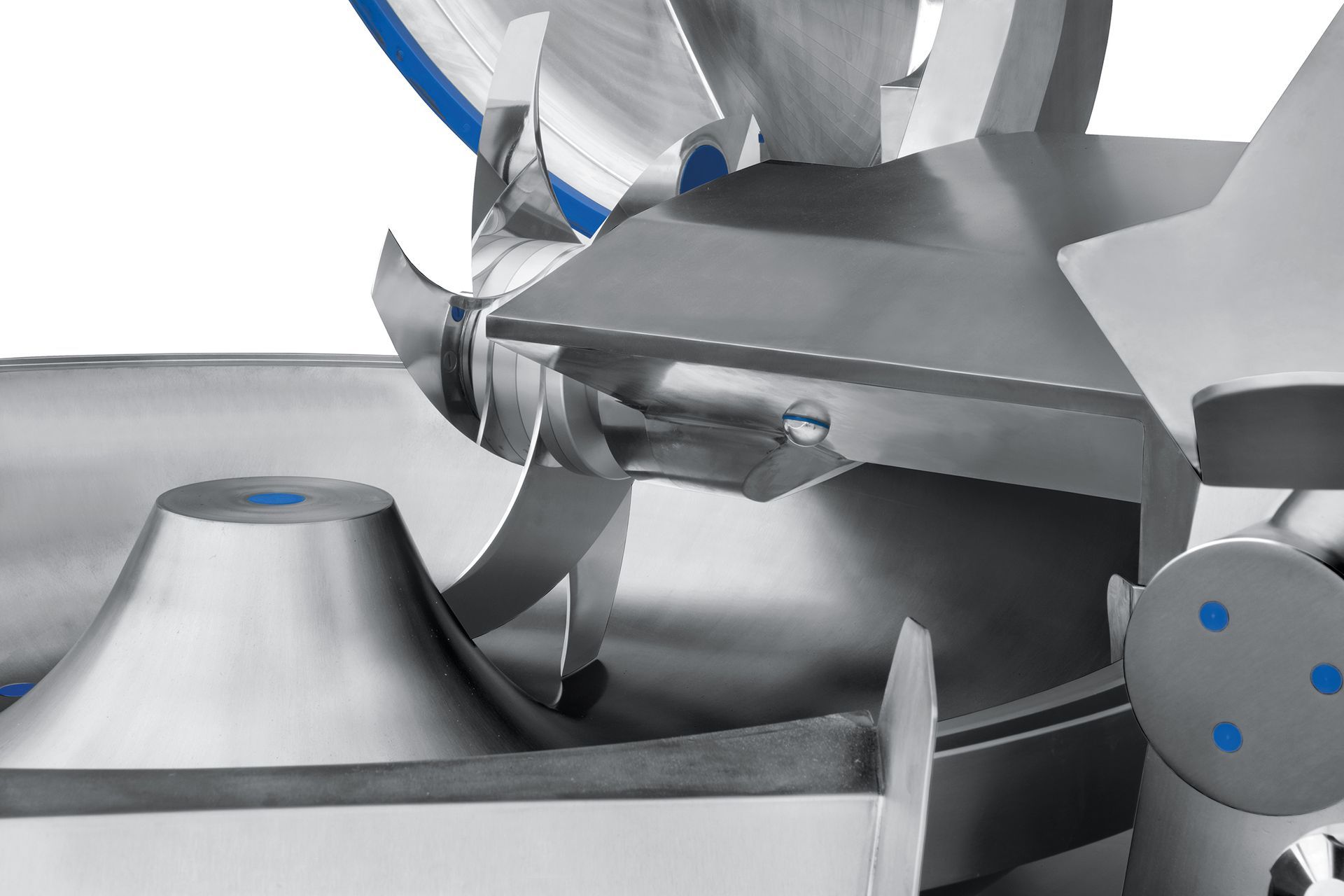

- High-Performance and Versatile Design: Features an optimized cutting chamber and an advanced knife head rotating at high speeds, allowing for efficient emulsification and mixing while maintaining high production output per hour.

- Precise Variable Control: Easily adjust all cutting parameters such as cutterhead rotation speed, bowl rotation speed, and temperature. The machine is capable of operating at any setting within its full range, ensuring optimal performance for your specific needs.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

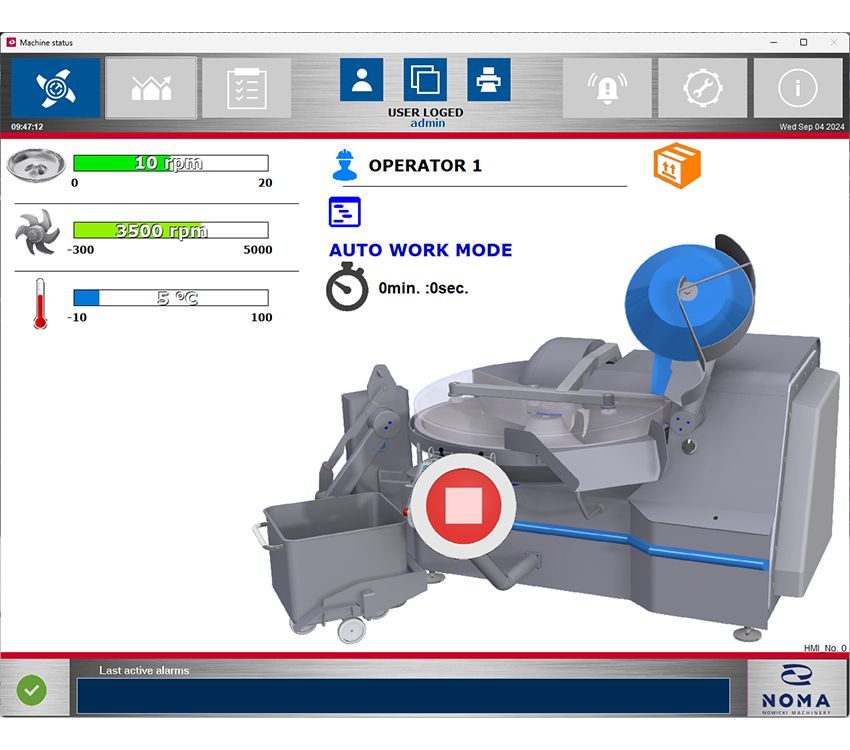

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 40 custom programs by adjusting variables such as cutterhead rotation speed, bowl rotation speed, and temperature

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

NOMA High-Speed Bowl Cutters are designed for producing homogenized meats, fat emulsions, and a wide range of meat fillings, including hot dogs, sausages, and salami. Their versatility makes them valuable across multiple industries, including red meat, poultry, fish processing, confectionery, fruit and vegetable production, ready meals, and pet food. These cutters ensure precise, high-quality results for a variety of products, making them essential in both large-scale and specialized production environments.

Farm-to-Retail Meat Processor

“Before our BAK Bowl Cutter, we were forcing hot dogs and emulsified products through grinders and mixers that just weren’t built for that job, and meanwhile good beef and pork trim was piling up or walking out the door as giveaway. Once we upgraded with BAK Food Equipment’s KN 125 HL bowl chopper with auto-load/unload, everything changed: mixing and emulsifying happened in one machine, emulsions became consistent, and we could finally build a full shelf—hot dogs, brats, cheese brats, and specialty sausages with real inclusions. Labor stopped getting burned on manual loading, trim turned into new SKUs instead of waste, and the retail case started selling itself. We even picked up a modest but profitable wholesale stream.” – Leadership Team, Midwest processor

You Might Also Like

Introduction to High-Speed Bowl Cutters

What is a high-speed bowl cutter?

A high-speed bowl cutter, also known as a bowl chopper, is a specialized piece of industrial food processing equipment designed to finely chop, emulsify, and mix a wide range of food products at high speeds. These machines feature a rotating bowl and a high-speed knife head, allowing for precise control over the texture and consistency of the final product. High-speed bowl cutters are essential in the production of homogenized meats, fat emulsions, and various meat fillings such as hot dogs, sausages, and salami. Their versatility also extends to applications in poultry, fish processing, confectionery, fruit and vegetable production, ready meals, and pet food.

Why are they essential in food processing?

High-speed bowl cutters play a critical role in modern food processing for several reasons. First, their ability to emulsify, homogenize, and mix ingredients at high speeds ensures a consistent and high-quality product, which is vital for both large-scale and specialized production environments. The advanced design of machines like the NOMA High-Speed Bowl Cutters, available through BAK Food Equipment, allows for precise variable control of cutting parameters such as cutterhead speed, bowl rotation speed and direction, as well as temperature. Processors can also rotate the knives and bowl in the opposite direction for efficient mixing without cutting. This flexibility enables operators to tailor the process to specific product requirements, resulting in faster production cycles, higher yields, and improved product uniformity. Additionally, features such as programmable control panels, durable stainless steel construction, and easy cleaning and maintenance make these machines reliable and efficient for demanding industrial applications. As a trusted supplier, BAK Food Equipment provides high-performance bowl cutters that help food processors achieve optimal results and maintain a competitive edge in the industry.

Key Features of Series KN Bowl Cutters

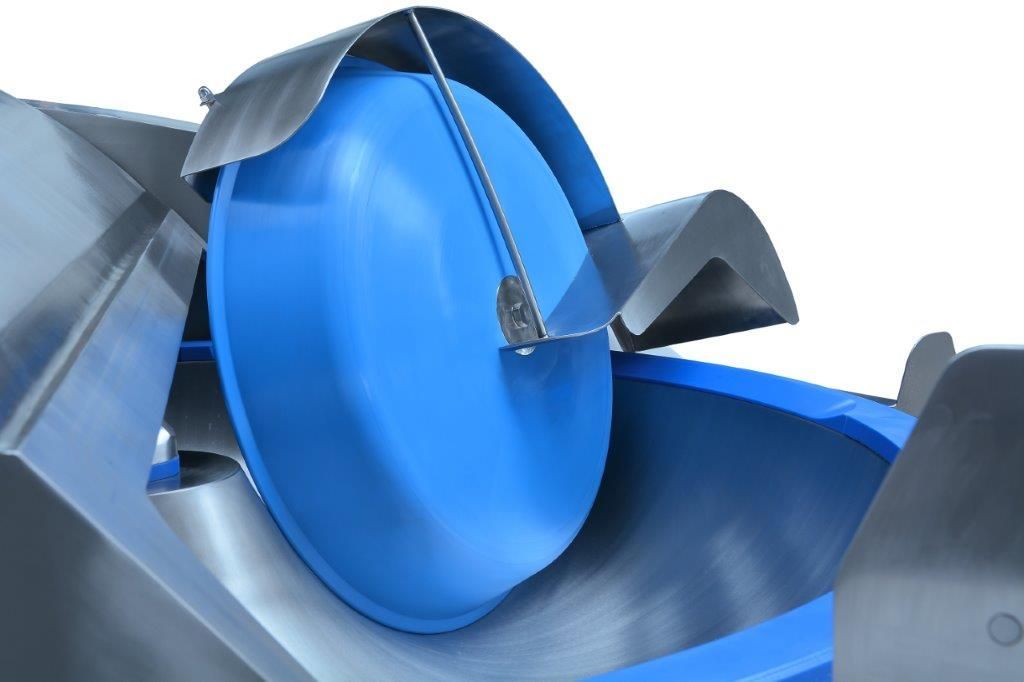

What makes the Series KN design unique?

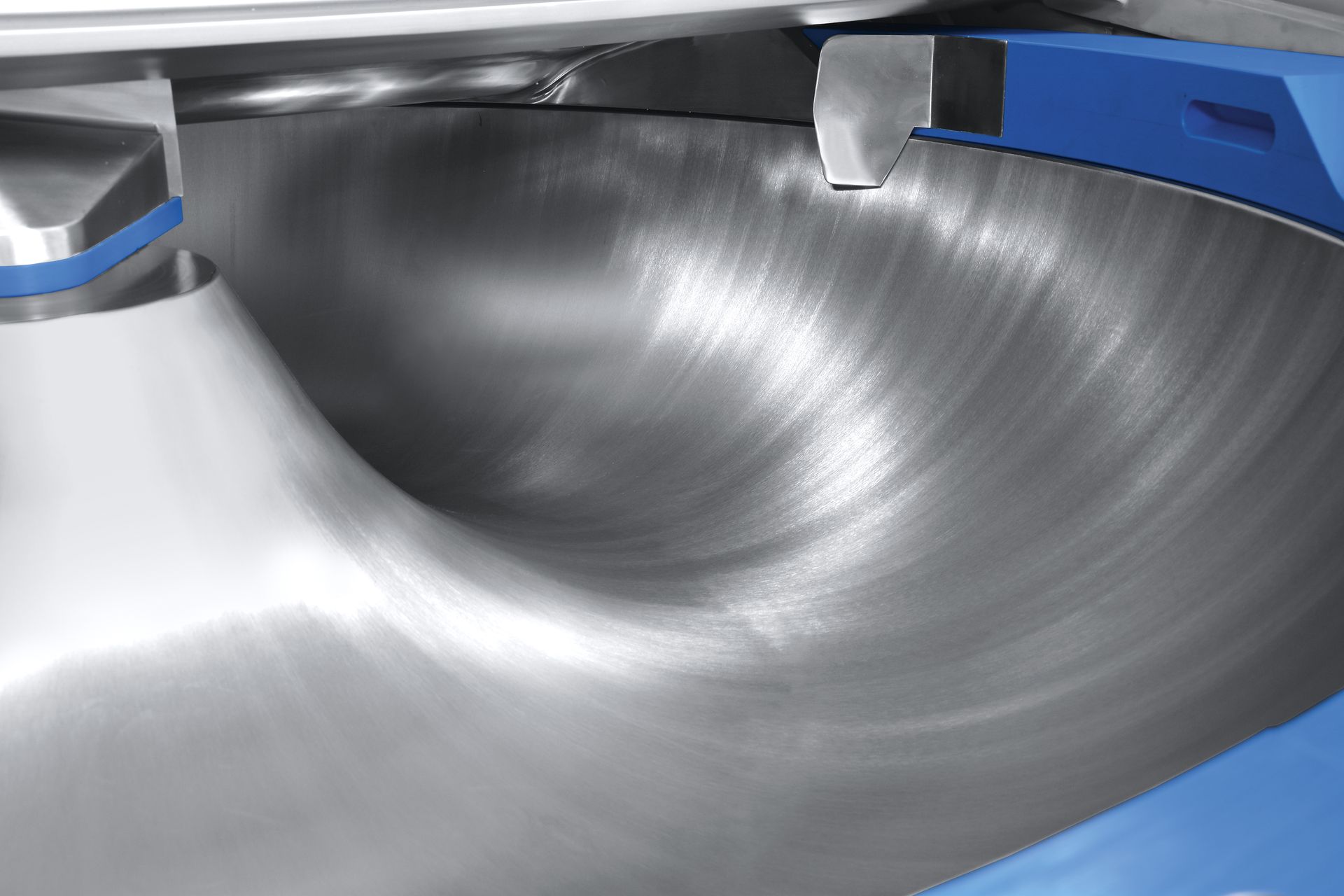

The Series KN high-speed bowl cutters from BAK Food Equipment stand out due to their robust, industrial-grade construction and advanced engineering. Each machine is built entirely from stainless steel, ensuring exceptional durability and longevity even in the most demanding food processing environments. The design features an optimized cutting chamber and a high-speed knife head, which together enable efficient emulsification and mixing. This makes the Series KN suitable for a wide range of applications, from producing homogenized meats and fat emulsions to preparing fillings for sausages, hot dogs, and salami. The wide bowl capacity range—from 60 to 750 liters—caters to both small-scale specialty producers and large-scale industrial operations, making these bowl cutters highly versatile.

How do these features improve efficiency and consistency?

The Series KN bowl cutters are engineered for maximum efficiency and product consistency. Variable speed control allows operators to precisely adjust the cutterhead rotation, bowl rotation, and temperature, ensuring optimal processing for each specific product. This level of control is further enhanced by an intuitive touch screen interface, which enables the creation and storage of up to 40 custom programs. Operators can quickly recall settings for different recipes, reducing setup time and minimizing the risk of human error. The easy-to-clean design streamlines routine maintenance, reducing downtime and supporting continuous production. These features, combined with the durable food equipment construction and programmable cutter capabilities, contribute to improved throughput, consistent product quality, and seamless integration into automated production lines.

Technical Specifications

What capacities and sizes are available?

The Series KN high-speed bowl cutters from BAK Food Equipment are engineered to meet a wide range of production needs, offering models with bowl volumes from 60 to 750 liters. This translates to maximum batch capacities ranging from 106 lbs (KN 60) up to 1,323 lbs (KN 750). The available models—KN 60, KN 90, KN 125, KN 200, KN 330, KN 550, and KN 750—allow processors to select the ideal size for their specific operation, whether for mid-sized facilities or high-output industrial plants. Each model is designed with a robust stainless steel construction, ensuring durability and longevity even in demanding food processing environments.

How does performance scale across different models?

Performance in the Series KN bowl cutter models is tailored to scale seamlessly with capacity. Smaller models like the KN 60 and KN 90 offer cutterhead emulsification speeds up to 6,000 and 5,500 RPM respectively, while larger models such as the KN 750 provide up to 3,500 RPM. This range of speeds, combined with variable control over both cutterhead and bowl rotation, ensures that each model can deliver precise emulsification and mixing, regardless of batch size. The advanced programmable control panel allows operators to store up to 40 custom programs, optimizing performance for diverse recipes and production requirements. Whether processing small specialty batches or large-scale continuous runs, these bowl cutter models maintain consistent product quality and efficiency, making them a scalable solution for any food processing operation.

Applications of Bowl Cutters in Food Processing

What products can be made with bowl cutters?

Bowl cutters, are essential machines in the food processing industry due to their ability to efficiently emulsify, mix, and homogenize a wide variety of ingredients. Their primary application is in the production of emulsified meats such as hot dogs, sausages, and salami, where they create a fine, uniform texture by rapidly cutting and blending meat and fat. Beyond traditional meat products, bowl cutters are also used to process poultry, fish, vegetables, fruit, and sauces, soups, and oil making them highly versatile. In the ready meal sector, these machines are employed to prepare fillings and mixtures for products like dumplings, meat pies, and spreads. Additionally, the confectionery industry utilizes bowl cutters for tasks such as blending fruit pastes and nut fillings. A growing area of application is pet food processing, where bowl cutters are used to produce homogenized, high-quality pet food blends that require consistent texture and particle size.

Which industries rely on them most?

Bowl cutters are indispensable across a range of food processing sectors. Red meat plants depend on these machines for the production of sausages, salami, and other emulsified meat products. Poultry processors use bowl cutters to create finely textured chicken and turkey products, while seafood facilities rely on them for seafood patties, fish cakes, surimi (imitation crab meat), and other processed seafood items. The versatility of bowl cutters also extends to companies specializing in prepared foods, where they are used to mix and homogenize ingredients for ready meals and convenience foods. The pet food industry is another significant user, leveraging bowl cutters to ensure the consistency and quality of their products. The ability of industrial bowl cutter machines to handle large capacities and a wide range of ingredients makes them a critical asset for any operation focused on meat emulsification, sausage production, pet food processing, and food homogenization.

Optional Systems and Add-Ons

What options are available for customization?

BAK Food Equipment’s high-speed bowl cutters can be tailored with a range of optional systems and add-ons to meet the specific needs of your production line. Key customization options include a water dosage system for precise liquid integration, hydraulic loading and unloading systems to streamline material handling, and a SCADA monitoring system for advanced automation and oversight. These options allow processors to adapt their bowl cutter machine to unique recipes, batch sizes, and operational requirements, ensuring maximum flexibility and efficiency in both large-scale and specialized environments.

How do these options improve performance?

Each add-on is designed to enhance the performance and reliability of your bowl cutter. The water dosage system ensures accurate and consistent liquid addition, which is critical for product quality and repeatability in applications such as sausage and emulsified meat production. Hydraulic loading and unloading systems significantly reduce manual labor, speed up batch changeovers, and minimize the risk of operator injury, all of which contribute to higher throughput and reduced downtime. The SCADA monitoring system brings smart automation to the process, enabling real-time data collection, remote oversight, and rapid troubleshooting. This not only improves consistency and traceability but also helps future-proof your operations by integrating seamlessly with broader automated food processing and industrial food technology platforms.

Why Choose BAK High-Speed Bowl Cutters

What sets BAK’s cutters apart from competitors?

BAK Food Equipment’s high-speed bowl cutters, developed in partnership with NOMA, stand out in the market for their proven reliability and advanced engineering. These machines are designed for demanding, large-scale food processing environments, offering a combination of high performance, versatility, and precision. The optimized cutting chamber and advanced knife head deliver efficient emulsification and mixing, ensuring consistent product quality and high production output per hour. Unlike many competitors, BAK’s bowl cutters feature precise variable control, allowing operators to adjust cutterhead and bowl rotation speeds, as well as temperature, to match specific processing requirements. The intuitive, programmable control panel enables the creation and storage of up to 40 custom programs, streamlining operations and reducing the risk of operator error. Built entirely from industrial-grade stainless steel, these machines are engineered for durability and longevity, minimizing downtime and replacement costs. Their robust construction and thoughtful design make them a trusted choice for food processors who demand both performance and reliability from their equipment.

How do they support food processors long term?

BAK’s high-speed bowl cutters are built to deliver long-term value for food processors. The use of high-quality stainless steel throughout the construction ensures exceptional durability, even in the most demanding production environments. This longevity translates to lower replacement and maintenance costs over the life of the equipment. The advanced control systems and customizable programming not only enhance operational efficiency but also support compliance with USDA, FDA, and HACCP standards, helping processors maintain food safety and quality. By delivering consistent yields and reducing product waste, these bowl cutters contribute directly to improved ROI in food processing operations. BAK’s commitment to customer support and its partnership with NOMA further ensure that processors have access to trusted food processing equipment and expert guidance throughout the lifespan of their investment. Whether producing homogenized meats, sausages, or a variety of other products, BAK’s industrial cutter solutions are trusted by leading processors across the meat, poultry, fish, confectionery, fruit and vegetable, ready meal, and pet food industries.

High-Speed Bowl Cutters/Chopper FAQs

What is a high-speed bowl cutter used for?

High-speed bowl cutters, also known as bowl choppers, are essential machines in the food processing industry. They are primarily used for emulsifying meats, homogenizing ingredients, and producing finely textured products such as sausages, salami, hot dogs, and other processed meats. Their advanced design allows for efficient mixing and cutting, making them indispensable for manufacturers seeking consistent, high-quality results across a wide range of applications.

How do industrial bowl cutters improve meat emulsification?

Industrial bowl cutters utilize high-speed rotating knives and bowls to finely chop and emulsify meat mixtures. This process ensures even distribution of fat and protein, resulting in a smooth, uniform texture that is critical for products like sausages and hot dogs. The precise variable control available on machines like the Series KN allows operators to adjust cutterhead and bowl speeds, as well as temperature, to achieve optimal emulsification for each specific recipe. This level of control leads to superior product consistency and quality.

What foods can be processed with a commercial bowl cutter?

Commercial bowl cutters are highly versatile and can process a wide variety of foods beyond traditional meat products. In addition to red meats, poultry, and seafood, these machines are suitable for vegetables, fruits, confectionery, ready meals, pet food, and soups, sauces, and oils. Their ability to homogenize and emulsify makes them valuable across multiple sectors, supporting both specialized and large-scale production needs.

What size bowl cutter do I need for my production line?

The appropriate size of a bowl cutter depends on your production scale and specific requirements. Smaller models, such as those with 60 to 125-liter bowl volumes, are ideal for independent processors or specialty product lines. Larger models, ranging from 330 to 750 liters, are designed for facilities with high-volume production demands. BAK Food Equipment offers a comprehensive range of sizes to ensure the right fit for any operation.

What optional systems are available with Series KN bowl cutters?

Series KN high-speed bowl cutters from BAK Food Equipment can be equipped with several optional systems to enhance productivity and automation. These include water dosage systems for precise ingredient control, hydraulic loading and unloading systems for efficient material handling, and SCADA monitoring systems for advanced process oversight and data collection. These options help streamline operations and support consistent, high-quality output.

How do bowl cutters compare to industrial grinders?

While both bowl cutters and industrial grinders are used in meat processing, they serve different functions. Grinders are designed to break down meat into smaller pieces but do not emulsify or homogenize the mixture. In contrast, bowl cutters are a more versatile machine. Bowl cutters can chop, mix, and emulsify products to your desired level of fineness. This makes them essential for products that require a smooth, uniform consistency, such as sausages and hot dogs. For applications demanding high-quality emulsification, bowl cutters are the preferred choice.

Are high-speed bowl cutters easy to clean and maintain?

Yes, high-speed bowl cutters from BAK Food Equipment are constructed entirely from stainless steel, ensuring durability and ease of cleaning. The machines are thoughtfully designed to make routine cleaning and maintenance straightforward, minimizing downtime and supporting food safety standards. Features such as accessible cutting chambers and intuitive control panels further simplify operation and upkeep.

Can bowl cutters be used for pet food and non-meat applications?

Absolutely. The versatility of high-speed bowl cutters extends to pet food production, as well as processing vegetables, fruits, confectionery, ready meals, and soups, sauces, and oils. Their ability to homogenize and emulsify a wide range of ingredients makes them a valuable asset for manufacturers across diverse food sectors.

For more information on our range of bowl cutters and emulsifiers, visit our Bowl Cutters & Emulsifiers page or explore our High-Speed Vacuum Bowl Cutters/Choppers for advanced processing solutions.