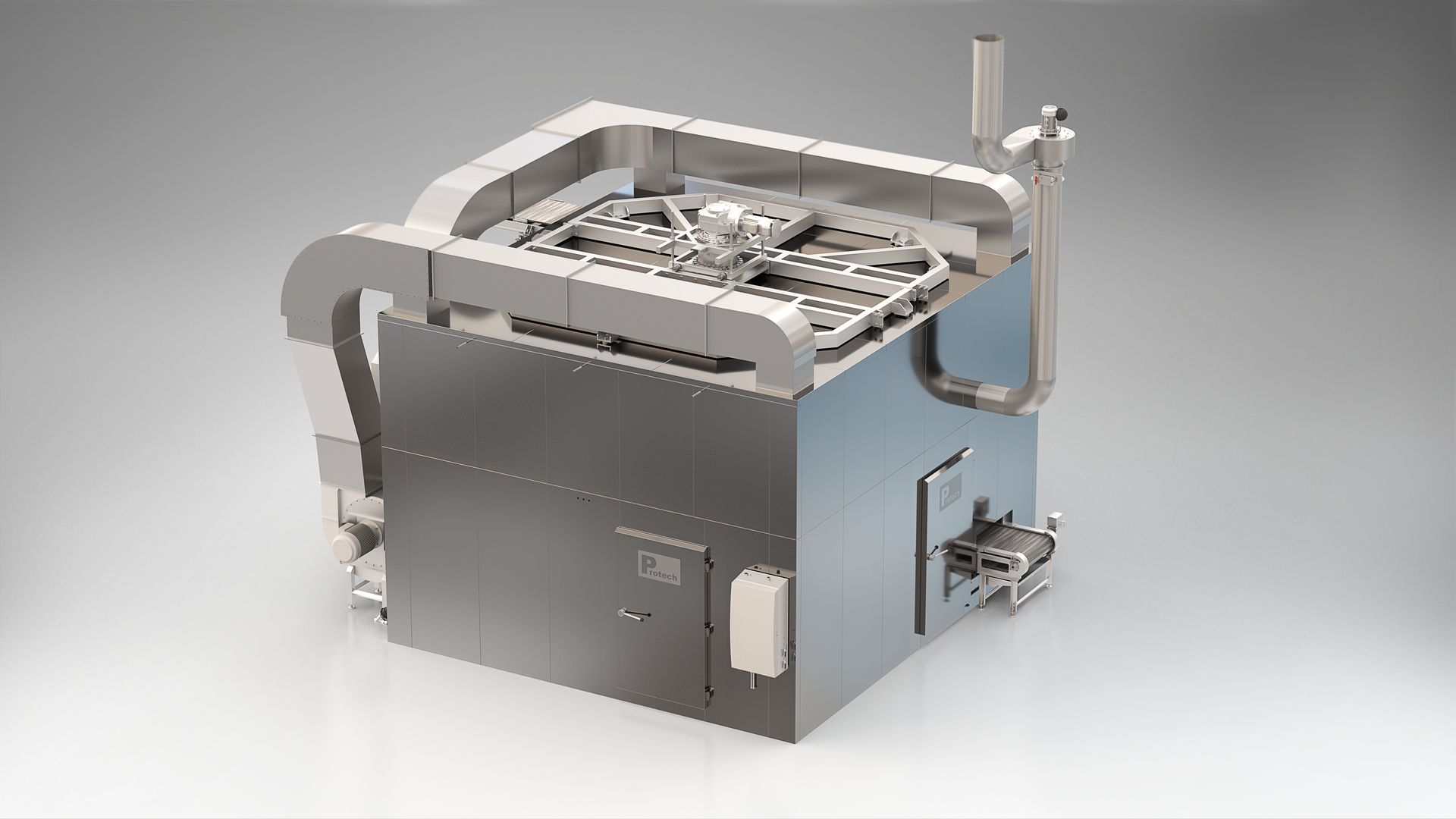

Automated Spiral Smoking Line for Industrial Food Processing with Natural Smoke

Smoking/Cooking/Chilling

Equipment Highlights

Natural Smoke, Atomized, or Both

Using natural smoke, atomized smoke or a combination, our spiral systems achieve any desired taste, texture, and color comparable to traditional batch smokehouses for products ranging from bacon to smoked salmon and any other products treated in a traditional chamber.

High Capacity Smoking System

Our system can produce 10,000+ Lbs. of bacon an hour.

Superior Product Movement & Logistics

Pork bellies move seamlessly via conveyors from brine injectors through the entire spiral system, resulting in fully smoked, cooked, and frozen bacon. This method eliminates the need for rail systems and manual labor to transport bacon to and from batch smokehouses, significantly increasing production efficiency.

No Combing or Hanging Required

Our spiral systems eliminate the need for combing and hanging, thereby increasing the yield of #1 bacon and reducing labor requirements. By preventing product damage that can occur from impaling pork bellies with hooks, our spirals maintain the integrity of the product.

Consistent Treatment of Each Pork Belly

Every pork belly is exposed to the same temperature and smoke conditions, resulting in a more consistent product compared to batch smokehouses, which cannot maintain uniform temperature and smoke concentration.

Customizable to Customer Specs

Each line is built to meet the specific needs of our clients, with customization options that include the number of drying, smoking, and freezing spirals, layout direction, optional liquid smoke drench, and variable throughput to suit different production demands.

Benefits

$2.4M Labor Savings Yearly

BAK’s design successfully reduced labor requirements from 50 employees to less than 2 per line (3 over 2 lines). Click for calculation details

$7.5M-$11.2M Yield Savings Yearly

Due to consistent treatment and no hanging, the spiral system results in significantly more #1 bacon and therefore higher yield numbers. Click for calculation details

Utility Savings

BAK estimates significant savings on energy. Due to the design of our system, our chambers maintain their temperature throughout production, whereas traditional batch houses must cool down and reheat after each batch.

Floor Space

Up to 60% reduction of required floor space

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments. Current lines in operation run 110+ hours a week.

Advanced Programmable Control Panel:

Our advanced programmable control system allows for the creation of customized programs tailored to specific product requirements. Parameters such as dwell time, smoke density, and temperature can be precisely controlled through the intuitive HMI, ensuring optimal results for each product.

Easy Cleaning and Maintenance:

Designed with a fully integrated Clean-In-Place system.

Applications

Our automated natural smoking, cooking, chilling line is designed to provide fully automated, high-efficiency processing for a wide range of smoked products. It excels in handling popular items like bacon, salmon, and ribs, ensuring consistent quality and flavor across large production volumes. The system is versatile and can be easily adapted to accommodate various other products.

Large Bacon Producer

"Before we introduced BAK’s automated spiral system, our bacon production rose and fell with Monday’s workforce. Now that we’ve streamlined the entire process—smoking, cooking, and chilling in a single continuous system—we’ve not only stabilized our output, but we’re producing better bacon than ever. It’s been a complete game-changer.“ – Leadership team

You Might Also Like

Production Efficiency & Throughput Advantages

How much product can the system process per hour?

BAK Food Equipment’s automated spiral smoking system is engineered for high-volume production, making it ideal for industrial bacon production and other smoked products. The system is capable of processing over 10,000 pounds of bacon per hour, with scalable configurations available to accommodate a variety of products such as salmon, ribs, and poultry. Each line is custom-built to meet specific throughput requirements, ensuring that both smaller and larger operations can benefit from the same level of efficiency and consistency. This high-capacity performance is achieved without sacrificing product quality, as every item receives uniform exposure to temperature and smoke, resulting in a consistently superior finished product.

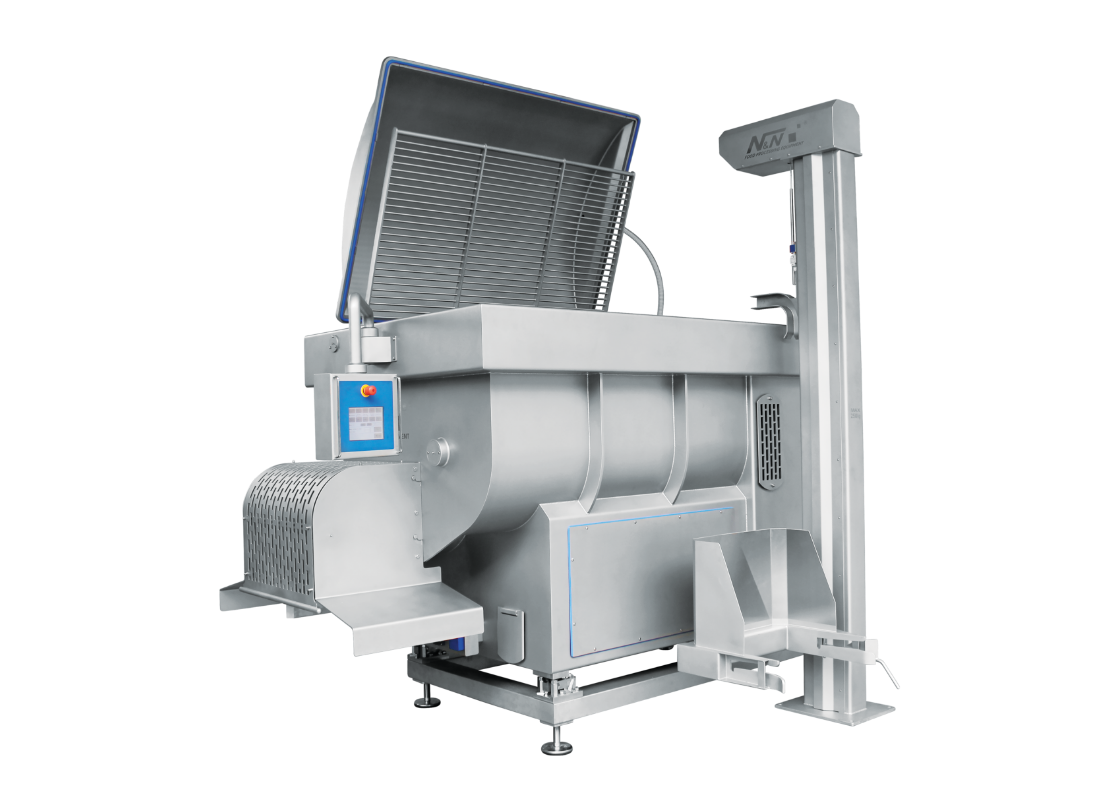

How does automation reduce manual handling and labor costs?

Automation is at the core of BAK’s spiral smoking system, dramatically reducing the need for manual labor throughout the production process. The system integrates automated conveyors that transport products seamlessly from brine injectors through smoking, cooking, chilling, and freezing stages. This eliminates the traditional need for rail systems and manual handling, such as combing and hanging, which not only reduces labor requirements but also minimizes the risk of product damage. In a recent case study, a facility utilizing BAK’s automated food processing line reduced its labor force from 50 employees to fewer than 2 operators per line, resulting in annual labor savings of over $2 million. This significant reduction in manual handling not only lowers costs but also improves workplace safety and product yield.

What impact does a spiral system have on downtime and production scheduling?

The spiral system’s continuous operation model offers substantial advantages over traditional batch processing, particularly in terms of minimizing downtime and optimizing production scheduling. Unlike batch smokehouses, which require cooldown and reheat cycles between runs, BAK’s spiral system maintains a consistent operating temperature throughout production. This allows for faster turnaround between product runs and virtually eliminates the bottlenecks associated with batch processing. The result is a more predictable and efficient production schedule, enabling plants to maximize throughput and respond more flexibly to changing demand. Additionally, the system’s advanced programmable control panel allows operators to quickly adjust parameters for different products, further enhancing plant efficiency improvements and reducing the risk of costly delays.

Product Quality & Consistency

How does the spiral system ensure uniform smoking and cooking?

The BAK Food Equipment automated spiral smoking system is engineered to deliver even exposure to temperature and smoke density for every product in the line. Unlike traditional batch smokehouses, where temperature and smoke concentration can fluctuate from one area to another, the spiral system’s design ensures that each product—whether bacon, salmon, ribs, or poultry—receives identical treatment as it moves through the spiral chamber. This uniform smoking process is achieved through precise control of dwell time, smoke density, and temperature, all managed by an advanced programmable control panel. The result is a consistently high-quality product with enhanced color, texture, and flavor that closely replicates the results of traditional smokehouses, but with greater repeatability and efficiency.

What design features help maintain product integrity?

A key advantage of the spiral system is its ability to process products without the need for hanging or impaling. Traditional methods often require products like pork bellies to be hung on hooks, which can damage texture and appearance, leading to downgraded product. The spiral system instead uses conveyors to gently transport products through each stage—smoking, cooking, and chilling—eliminating the risk of tearing or deformation. This approach preserves the natural integrity of the product, ensuring that the finished items maintain their premium look and feel, which is critical for food product quality control and premium meat processing.

What effect does the system have on yield of premium-grade product?

The spiral system’s consistent treatment and gentle handling directly contribute to measurable yield improvement. By eliminating the need for combing and hanging, the system significantly increases the proportion of #1 grade bacon and reduces the amount of #2 product. For example, traditional processes typically yield about 80% #1 bacon and 15% #2 bacon, while the spiral system can achieve yields as high as 93% #1 bacon and only 3% #2 bacon. This yield optimization translates into substantial cost savings and a higher volume of premium-grade product, making the spiral system a valuable investment for processors focused on quality and profitability.

Customization & Scalability

Can the system be tailored to specific plant layouts or product types?

BAK Food Equipment’s automated spiral smoking line is engineered with flexibility at its core, making it highly adaptable to a wide range of plant layouts and product types. Each system is custom-built to client specifications, allowing for the configuration of the number of drying, smoking, and chilling/freezing spirals to match the unique requirements of your facility and product portfolio. Whether you are processing bacon, salmon, ribs, poultry, or other smoked products, the system’s modular design ensures seamless integration into existing or new plant layouts. Left- or right-hand layout configurations are available, enabling optimal use of available floor space and supporting plant layout optimization. This adaptability ensures that the system can be tailored to both current needs and future expansion plans, making it a truly scalable food processing solution.

What options are available for different production volumes?

The spiral smoking system from BAK Food Equipment is designed to accommodate a wide range of production volumes, from smaller operations to high-capacity facilities. Through customizable throughput options, the system can be scaled to produce as little or as much product as required—up to 10,000+ lbs. of bacon per hour in some configurations. This variable throughput capability allows processors to match their equipment investment to their current production demands, while also providing the flexibility to scale up as business grows. The system’s modular nature means that additional spirals or capacity upgrades can be incorporated as needed, ensuring long-term value and adaptability.

What add-ons or process integrations are possible?

To further enhance operational efficiency and product quality, BAK’s spiral smoking line offers a range of add-ons and integration options. An optional liquid smoke drench system can be included for processors seeking alternative flavor profiles or faster processing times. The system is also designed for seamless integration with upstream processes such as brine injection and tumbling, as well as downstream operations like slicing and packaging. This turnkey approach enables the creation of fully automated production lines, reducing manual handling, improving product consistency, and streamlining workflow from raw product to finished, packaged goods. By supporting integration across the entire production chain, BAK’s custom spiral smoker systems help processors achieve higher yields, lower labor costs, and greater overall efficiency.

Operational Cost Savings

How much can plants save on labor annually?

One of the most significant advantages of BAK Food Equipment’s automated spiral smoking system is the dramatic reduction in labor costs. Traditional batch smokehouses typically require a large workforce—often around 50 employees per line—to handle tasks such as loading, unloading, combing, and hanging products like bacon. In contrast, BAK’s spiral system streamlines the entire process, reducing labor needs to fewer than two operators per line. For a two-line system, this equates to just three employees in total. With an average total cost per employee of $50,000, plants can realize annual labor savings of approximately $2.4 million. This reduction not only lowers direct labor expenses but also minimizes the risks and inefficiencies associated with manual handling.

How does the spiral design reduce utility costs?

The spiral smoking system is engineered for energy efficiency. Unlike traditional batch smokehouses, which require frequent cooling and reheating between batches, the spiral system maintains a stable temperature throughout continuous production. This consistent thermal environment significantly reduces energy consumption, as there is no need to repeatedly bring chambers up to temperature. The result is a notable decrease in utility costs, making the system an energy-efficient solution for high-volume food processing operations.

How does space efficiency translate to cost efficiency?

Space utilization is another area where the spiral system delivers substantial cost savings. The compact, vertical design of the spiral line can reduce the required floor space by up to 60% compared to conventional batch setups. This reduction in plant footprint not only allows for more efficient use of existing facilities but can also defer or eliminate the need for costly building expansions. Additionally, less space means lower overhead costs for utilities, maintenance, and facility management, all of which contribute to a stronger return on investment (ROI) in processing equipment. By maximizing throughput within a smaller footprint, plants can achieve higher productivity and profitability per square foot.

In summary, BAK Food Equipment’s automated spiral smoking system delivers operational cost savings through reduced labor requirements, lower energy usage, and significant plant footprint reduction—key factors that drive cost savings in food manufacturing and improve overall ROI.

Applications Across Product Lines

What products can be processed in the spiral line?

BAK Food Equipment’s automated spiral smoking line is engineered for exceptional versatility, making it suitable for a broad spectrum of smoked and cooked products. The system is particularly renowned for its performance with high-demand items such as bacon, salmon, and ribs. For bacon, the spiral system delivers consistent quality and flavor, processing over 10,000 pounds per hour while maintaining product integrity and maximizing yield. Salmon and other seafood products also benefit from the system’s natural smoke design, which imparts traditional taste and texture without the inconsistencies of batch processing. Ribs, along with other smoked meats, are treated uniformly, ensuring each piece meets exacting standards for color, texture, and flavor.

Can the system handle both meat and seafood?

Yes, the spiral smoking system is designed to accommodate both meat and seafood products with equal efficiency. Its advanced programmable control panel allows operators to tailor smoke density, temperature, and dwell time to the specific requirements of each product type. This flexibility ensures that whether processing pork bellies, salmon fillets, or other proteins, the system delivers optimal results. The seamless movement of products through the line—without the need for combing, hanging, or manual transfer—further supports the processing of delicate seafood alongside robust meats, all while maintaining high throughput and consistent quality.

How adaptable is it to new recipes or market demands?

Adaptability is a core strength of BAK’s spiral smoking line. The system is fully customizable, with options to adjust the number of drying, smoking, and freezing spirals, as well as layout direction and throughput capacity. This makes it easy to introduce new recipes or respond to changing market trends, such as the growing demand for plant-based proteins or specialty deli meats. The intuitive HMI and programmable controls enable quick recipe changes and minimal downtime between product runs, supporting a flexible food manufacturing environment. Whether scaling up for a new product launch or switching between different protein categories, the spiral system is built to keep pace with evolving production needs.

In addition to its primary applications, the spiral line is well-suited for poultry, deli meats, and plant-based protein products, making it a true multi-product processing solution. Its robust, stainless steel construction and integrated Clean-In-Place system ensure durability and ease of maintenance, even in demanding, high-volume operations.

Why Choose BAK Spiral Smoking Systems

What differentiates your spiral smoking line from competitors?

BAK spiral smoking systems stand apart in the industry due to their innovative design, operational efficiency, and proven results. Unlike traditional batch smokehouses, our patent pending spiral systems use natural smoke to deliver the same authentic taste, texture, and color for a wide range of products—including bacon, salmon, ribs, and poultry—while dramatically increasing throughput and consistency. Our high-capacity systems can process over 10,000 pounds of bacon per hour, and the fully automated product movement eliminates the need for manual labor, rail systems, or the combing and hanging of products. This not only reduces labor requirements but also preserves product integrity by preventing damage from hooks or manual handling. Every product receives uniform exposure to temperature and smoke, ensuring a consistently high-quality result that batch systems cannot match. Additionally, each system is custom-designed to meet the specific needs of our clients, with flexible options for throughput, layout, and process steps.

What proof points support performance claims?

Our performance claims are backed by documented customer savings and operational data. For example, BAK’s spiral smoking systems have enabled customers to reduce labor from 50 employees to fewer than 2 per line, resulting in annual labor savings of over $2.4 million. The system’s ability to consistently produce more #1 grade bacon—thanks to uniform treatment and the elimination of hanging—translates to additional savings of $7.5 to $11.2 million per year. Customers also benefit from significant utility savings, as our chambers maintain optimal temperatures throughout production, unlike batch houses that require frequent reheating. Furthermore, our spiral systems require up to 60% less floor space, making them ideal for facilities looking to maximize production within a limited footprint. Built from industrial-grade stainless steel, these systems are engineered for durability and reliability, with current installations running over 110 hours per week. Our advanced programmable control panels and integrated Clean-In-Place systems further enhance operational efficiency and ease of maintenance, supporting long-term performance and customer satisfaction.

With decades of engineering experience, BAK Food Equipment provides not only custom design and full installation support but also ongoing technical assistance and readily available parts, ensuring that our clients receive comprehensive service throughout the lifecycle of their equipment. As a leading industrial smoking system manufacturer, we are committed to delivering commercial smoking solutions that drive measurable ROI and operational excellence.

FAQs: Automated Spiral Smoking Line

How does an automated spiral smoking line differ from a traditional batch smokehouse?

An automated spiral smoking line fundamentally changes the way products are processed compared to traditional batch smokehouses. Instead of relying on manual loading, unloading, and rail transport, the spiral system uses conveyors to move products continuously through smoking, cooking, and chilling stages. This continuous flow eliminates the need for manual handling, significantly reduces labor requirements, and ensures each product receives uniform exposure to smoke and temperature. The result is a more consistent product and a streamlined, efficient production process.

What types of products can be processed on a spiral smoking line?

While bacon is a primary application, the versatility of the spiral smoking line extends to a wide range of products. The system is designed to handle not only bacon but also salmon, ribs, poultry, deli meats, and even plant-based proteins. Its customizable design allows it to be tailored to a facility’s specific product mix and throughput goals, making it suitable for diverse processing needs. For more information on the range of products, visit our Applications page.

How much throughput can the system handle per hour?

Throughput capacity is one of the key strengths of the automated spiral smoking line. Depending on the configuration, a single line can process over 10,000 pounds of bacon per hour. This high-volume capability makes the system ideal for large-scale operations seeking to maximize productivity and efficiency.

What kind of labor savings can I expect from a spiral system?

The labor savings with a spiral system are substantial. For example, a two-line installation has reduced staffing needs from 50 operators to fewer than 3, resulting in annual labor cost savings of more than $2 million. This dramatic reduction is achieved by automating product movement and eliminating manual tasks such as hanging, loading, and unloading.

Does the system improve product yield?

Yes, the spiral system is designed to maximize product yield. By eliminating the need for combing and hanging, the system prevents product damage and increases the percentage of #1 grade bacon. Customers typically see $7–11 million in additional yield annually compared to traditional smoking processes, thanks to the consistent treatment and gentle handling of each product.

How does the spiral line reduce utility costs?

Traditional batch smokehouses lose energy during cool-down and reheat cycles between batches. In contrast, the spiral system maintains a consistent temperature throughout production, minimizing energy waste and reducing utility costs. This continuous operation not only saves energy but also contributes to overall process efficiency.

How much floor space does an automated spiral smoking line require?

Spiral smoking lines are designed to be space-efficient. Compared to batch smokehouses, they can reduce required floor space by up to 60%. This compact footprint frees up valuable space for other operations within your facility, supporting better plant layout and workflow.

Can the spiral smoking system be customized for my facility?

Absolutely. Each spiral smoking line is tailored to the specific needs of the customer. Customization options include different spiral configurations, throughput levels, layout direction, optional liquid smoke integration, and more. This flexibility ensures the system fits seamlessly into your plant and meets your production requirements.

What about cleaning and maintenance?

The spiral smoking line is constructed entirely from stainless steel for durability and ease of maintenance. It features a fully integrated Clean-In-Place (CIP) system, allowing for fast and efficient sanitation with minimal downtime. This design supports high standards of hygiene and operational reliability.

How do I control and monitor the system?

Operators manage the spiral smoking line through an advanced programmable Human Machine Interface (HMI) panel. This intuitive control system allows precise adjustment of parameters such as dwell time, smoke density, and temperature, ensuring repeatable, high-quality results across multiple product runs.

For more information about our automated spiral smoking line or to discuss your specific requirements, please contact us or visit our Service page.