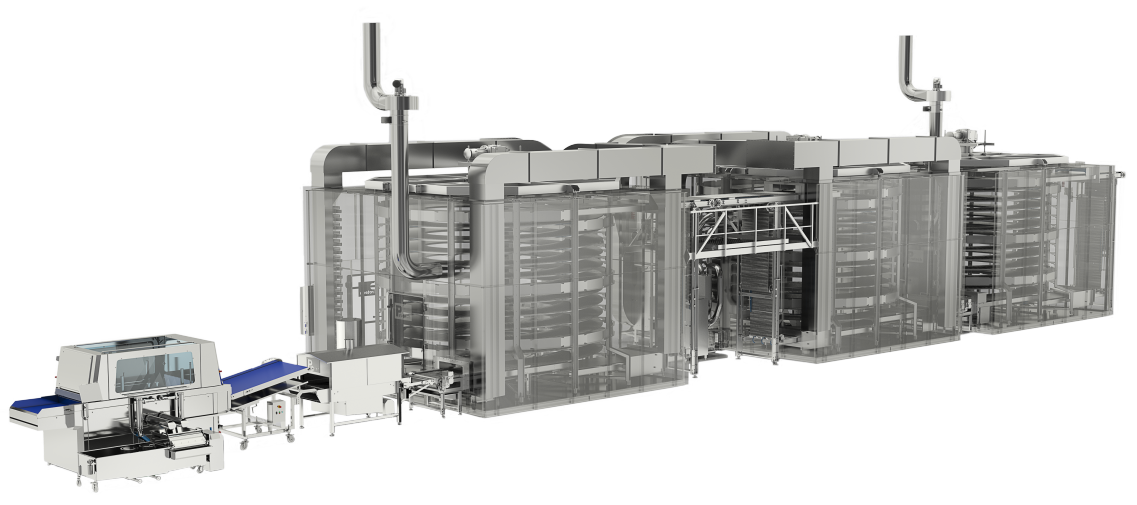

Natural and Liquid Smoke Generators

Size Ranges

Up to 12 Trolleys

Type

Woodchip, Sawdust, Liquid Smoke

- Comprehensive Flavor Control: Our smoke generators provide full control over the entire smoking process, whether using wood chips, sawdust, or liquid smoke. This system, paired with our smoke chambers, delivers a complete, time-saving, and cost-effective solution for producing high-quality, flavorful products.

- Scalable Smoke Generator:

A single smoke generator can support a smokehouse of up to 12 trolleys, with the option to use multiple generators together for larger smokehouses.

- * Using Protech’s smokehouses

- Enhanced Safety Features: Each generator is equipped with safety features like automatic fire extinguishers, making them both reliable and efficient for a variety of smoking applications.

Why Choose BAK

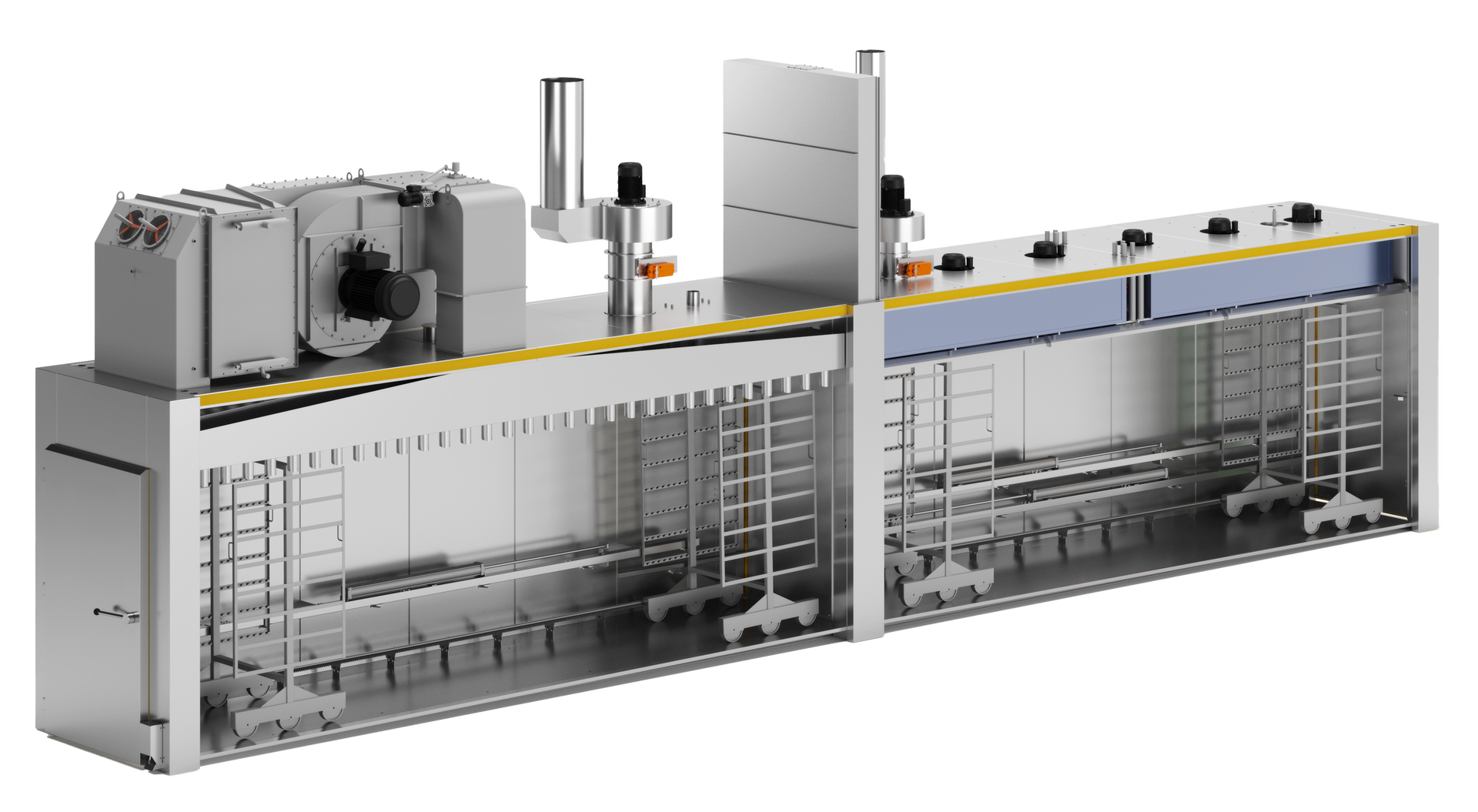

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments

Integrated PLC Controls:

Our smoke generators, equipped with a built-in PLC, connect directly to the chamber to automatically initiate and manage smoking sequences, ensuring precise control throughout the process.

Easy Cleaning and Maintenance:

Thoughtfully designed with an integrated CIP system to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

Our smoke generators are designed to meet the diverse needs of food processors, providing precise control for smoking a wide variety of products such as meats, fish, and cheeses. Whether using wood chips, sawdust, or liquid smoke, these generators are ideal for achieving the perfect flavor profile and texture for both hot and cold smoking applications. They are well-suited for small-scale artisanal producers and large-scale industrial operations, delivering consistent results with adjustable smoke density and seamless integration with smoke chambers.

Large Bacon Producer

"Before we introduced BAK’s automated spiral system, our bacon production rose and fell with Monday’s workforce. Now that we’ve streamlined the entire process—smoking, cooking, and chilling in a single continuous system—we’ve not only stabilized our output, but we’re producing better bacon than ever. It’s been a complete game-changer.“ – Leadership team