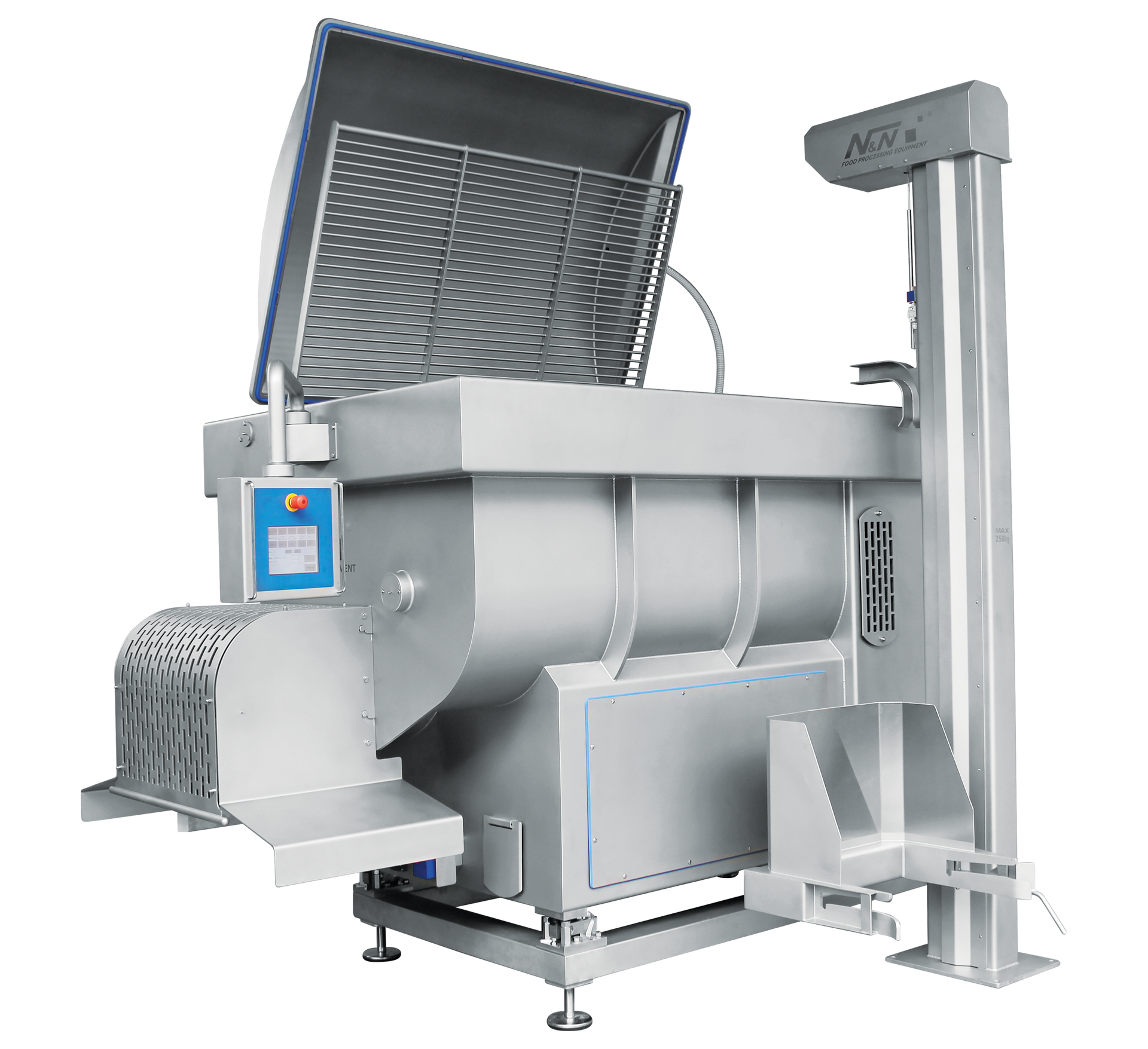

Series MIX Z/ZV

Industrial Intermeshing Z-Type Shaft Mixers

Bowl Volume

300-2,600

Liters

Max Mixing Capacity

400-3,500

Lbs

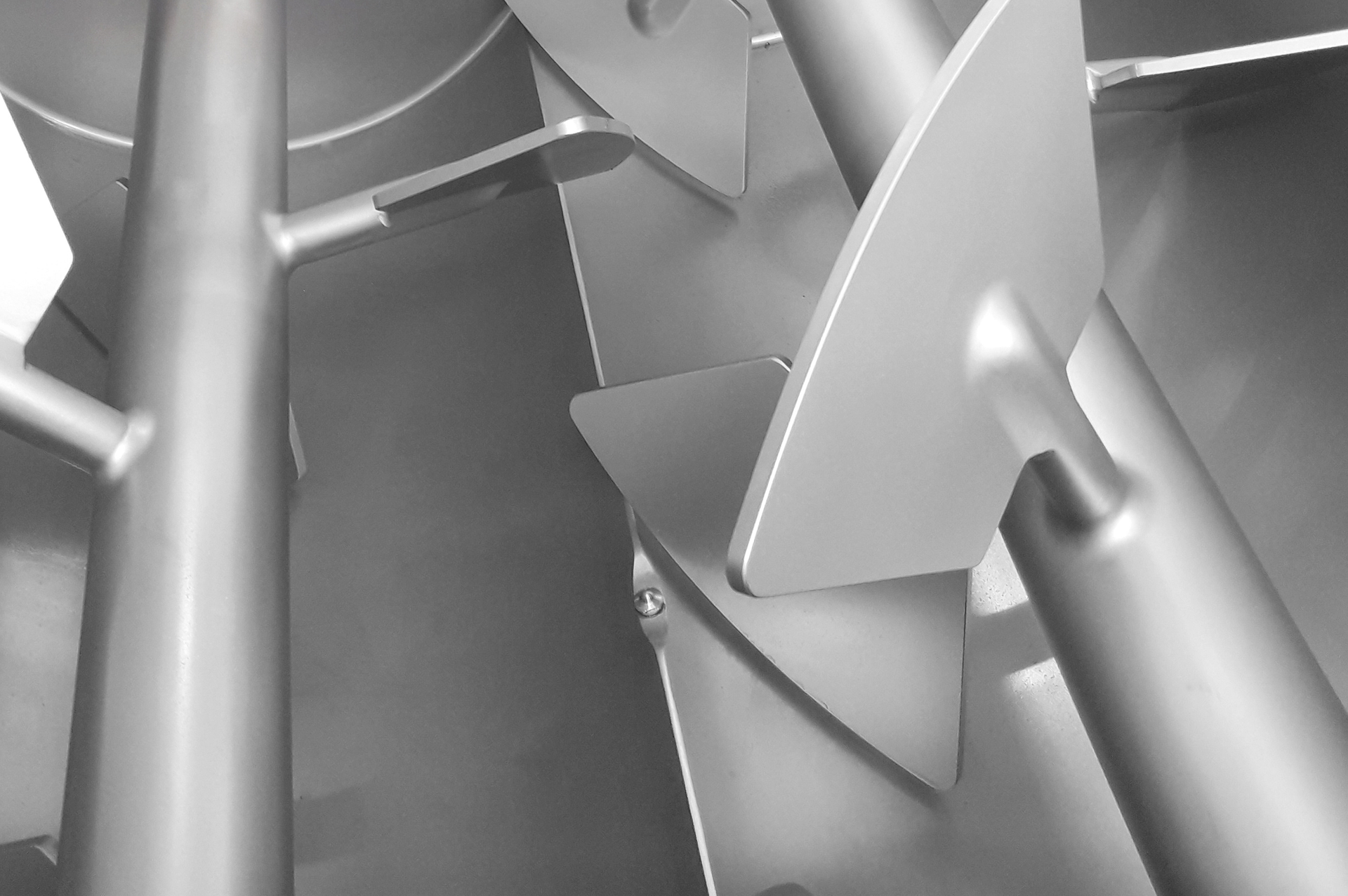

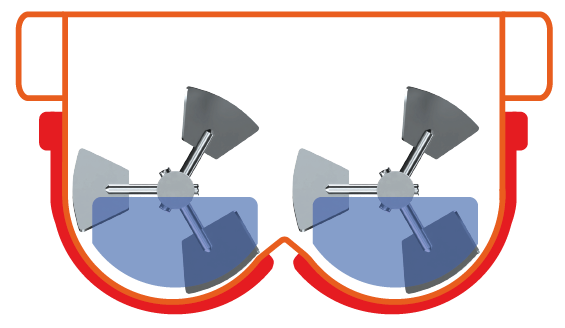

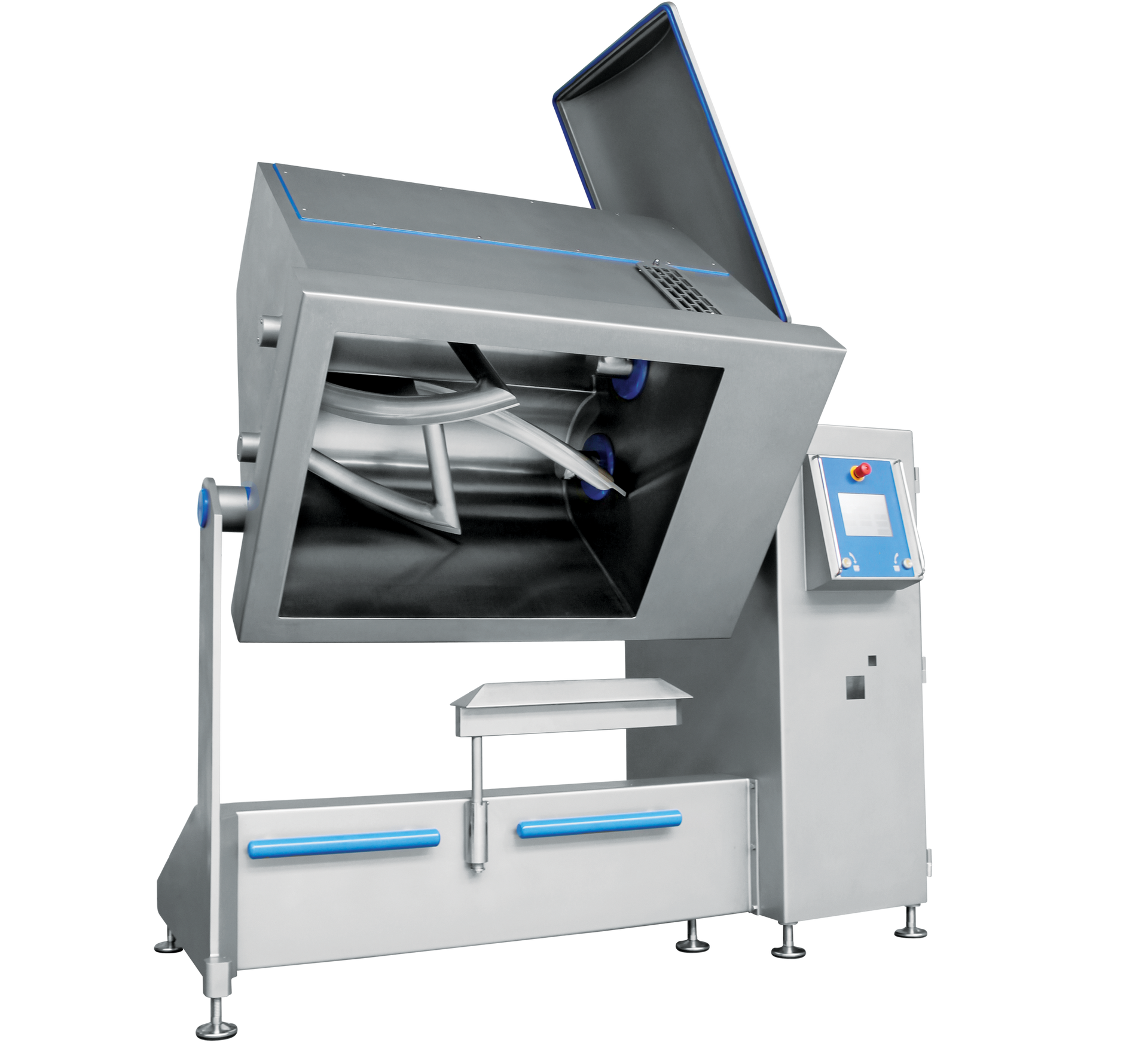

- Intermeshing Z-Type Shafts: Features dual intermeshing Z-type shafts at the same height, rotating at a preset speed either inward or outward, delivering efficient and consistent results for intensive mixing applications.

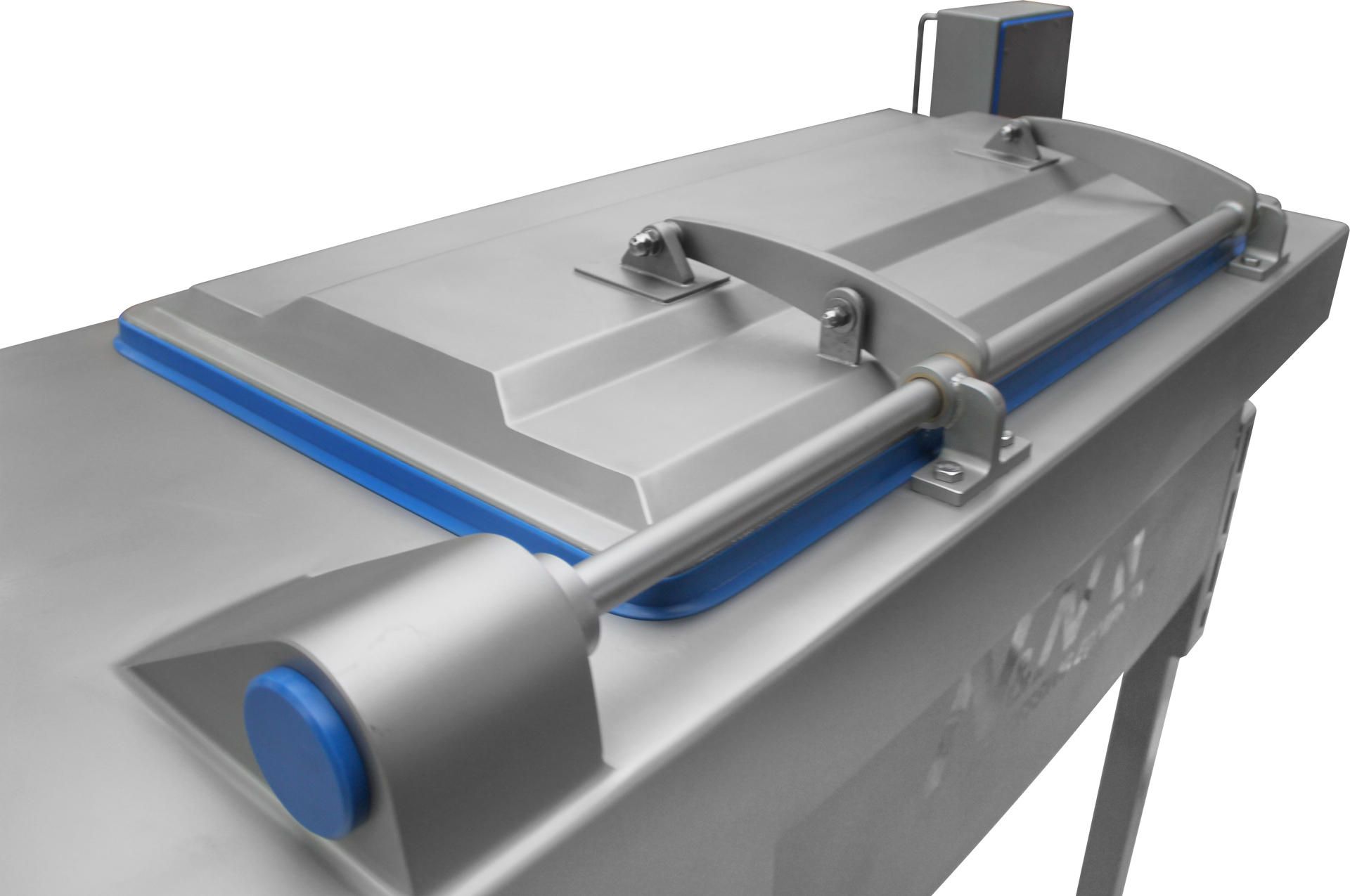

- Vacuum Option: Equipped with a reinforced bowl and airtight top cover, allowing up to 99% vacuum, which enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming.

- Hydraulic Unloading : Fitted with a hydraulic system for opening the mixing chamber cover and tilting the bowl for unloading, allowing quick and easy emptying.

- Variable speed: Offers precise speed adjustments, allowing the shafts to rotate at any desired speed within the machine's range.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

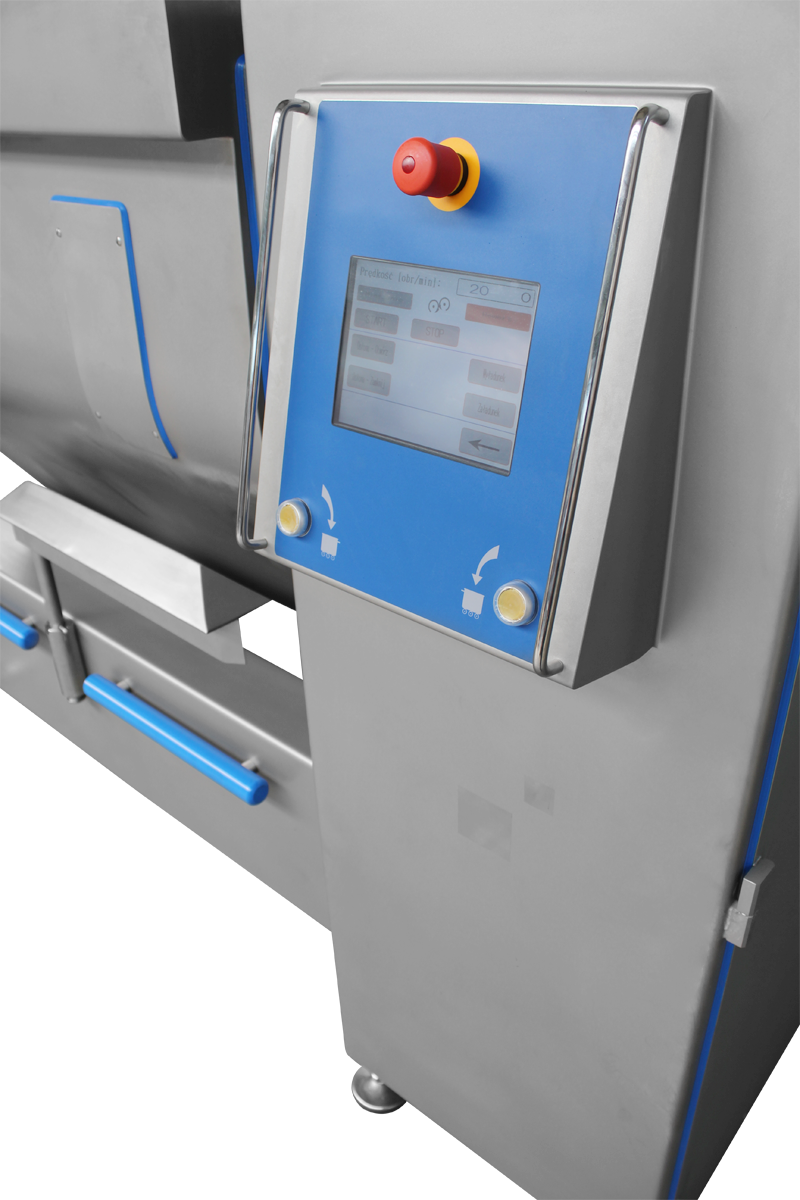

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as shaft rotation speed, shaft rotation direction, and vacuum level.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient

Technical Information

Mix Z

Mix ZV

Applications

The N&N MIX Z and MIX ZV series mixers are built for intensive mixing of thick, dense meat fillings, such as those used in kebab production. They are also designed for processing heavy bakery and confectionery mixtures.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to Intermeshing Z-Type Shaft Mixers

What are intermeshing Z-type shaft mixers?

Intermeshing Z-type shaft mixers are advanced industrial mixing systems engineered for intensive, high-density mixing applications. These mixers feature two Z-shaped shafts positioned at the same height within the mixing chamber. The shafts rotate either inward or outward at preset or variable speeds, creating a powerful intermeshing action that ensures thorough and uniform blending of even the most challenging ingredients. This Z-type mixing mechanism is particularly effective for applications where high torque and consistent results are essential, such as in the production of thick meat emulsions, dense bakery doughs, and confectionery mixes.

BAK Food Equipment offers the MIX Z and MIX ZV series of intermeshing Z-type shaft mixers, with bowl volumes ranging from 300 to 2,600 liters and maximum mixing capacities from 400 to 3,500 lbs. The MIX ZV models are equipped with reinforced bowls and airtight covers, allowing up to 99% vacuum for advanced mixing applications. Both series feature durable stainless steel construction, variable speed controls, hydraulic unloading, and intuitive programmable control panels, making them a reliable and versatile solution for demanding food processing environments.

What types of food processing applications are they ideal for?

Intermeshing Z-type shaft mixers are ideally suited for food processing tasks that demand intensive mixing of thick and dense materials. They excel in the preparation of meat fillings for products like kebabs, as well as in the processing of heavy bakery and confectionery mixtures. The robust design and high-torque mixing action make these mixers a preferred choice for applications where standard mixers may struggle to achieve the desired consistency and homogeneity. Additionally, the vacuum mixing technology available in models like the MIX ZV enhances protein extraction, liquid absorption, and the even distribution of spices and additives, while also eliminating air bubbles prior to emulsification, filling, or forming.

How do these mixers differ from paddle or ribbon mixers?

Unlike paddle or ribbon mixers, intermeshing Z-type shaft mixers utilize dual Z-shaped shafts that move in a coordinated inward or outward motion. This unique design delivers significantly higher torque and more intensive mixing, making it possible to process high-density mixtures. The intermeshing action ensures that all ingredients are thoroughly incorporated, reducing mixing times and improving product consistency. Furthermore, the availability of vacuum mixing technology and hydraulic unloading systems in the MIX Z and MIX ZV models provides additional benefits, such as improved product quality, easier emptying, and enhanced process control.

Performance & Applications

What types of products benefit from intermeshing Z-type mixers?

Intermeshing Z-type mixers are engineered to excel in the most demanding industrial food mixing applications, particularly where product density is high. These mixers are ideal for processing dense meat fillings, such as those required in kebab production, as well as heavy bakery doughs, confectionery pastes, and plant-based protein mixtures. Their robust design and dual intermeshing shafts ensure thorough and uniform mixing, making them a preferred choice for manufacturers seeking consistent texture and flavor distribution in their products. The ability to handle both traditional and innovative food products, including high-protein and plant-based formulations, highlights their versatility across a wide range of food processing sectors.

How do these systems handle heavy or sticky materials?

The intermeshing Z-type shaft mixers from BAK Food Equipment are specifically designed to manage heavy, sticky, and dense mixtures with ease. The dual Z-type shafts rotate at preset or variable speeds, creating an intensive mixing action that effectively breaks down and blends even the most challenging ingredients. The reinforced stainless steel construction and airtight top cover (with up to 99% vacuum capability in ZV models) further enhance the system’s ability to process sticky materials by improving protein extraction, liquid absorption, and additive distribution. Hydraulic unloading and easy-clean features ensure that even after processing dense or adhesive mixtures, the system can be quickly emptied and maintained, minimizing downtime and maximizing productivity.

Why are they suited for meat and bakery production lines?

Intermeshing Z-type mixers are particularly well-suited for meat processing equipment and bakery production line machinery due to their ability to deliver consistent, high-quality results. For meat applications, such as kebab or sausage fillings, the mixers ensure uniform distribution of spices, additives, and proteins, which is critical for product quality and safety. In bakery and confectionery settings, they provide the intensive mixing required for heavy doughs and pastes, supporting the development of desired textures and structures. Their programmable control panels allow operators to store and recall up to 100 custom mixing programs, ensuring repeatability and efficiency in large-scale production environments. Additionally, features like temperature monitoring, jacketed bowls for heating or cooling, and integrated loading systems make these mixers easy to integrate into automated production lines, supporting the evolving needs of modern food manufacturers.

Why Choose BAK Food Equipment

What sets BAK’s mixing systems apart from competitors?

BAK Food Equipment stands out in the food processing industry by offering intermeshing Z-type shaft mixers that are engineered for intensive mixing applications across a wide range of product types and capacities. Our equipment is engineered to meet the needs of your production, whether you’re processing dense meat fillings for kebabs, heavy bakery doughs, or confectionery mixtures. These systems can be customized to meet any unique requirements you have if necessary. Our mixers feature dual intermeshing Z-type shafts that rotate at preset or variable speeds, ensuring efficient, consistent, and thorough mixing results. The option for vacuum mixing—up to 99% vacuum—enhances protein extraction, liquid absorption, and additive distribution, while eliminating air bubbles for superior product quality. With a variety of bowl volumes and maximum mixing capacities available, BAK can tailor a solution to fit your exact requirements.

How does BAK ensure long-term reliability and customization?

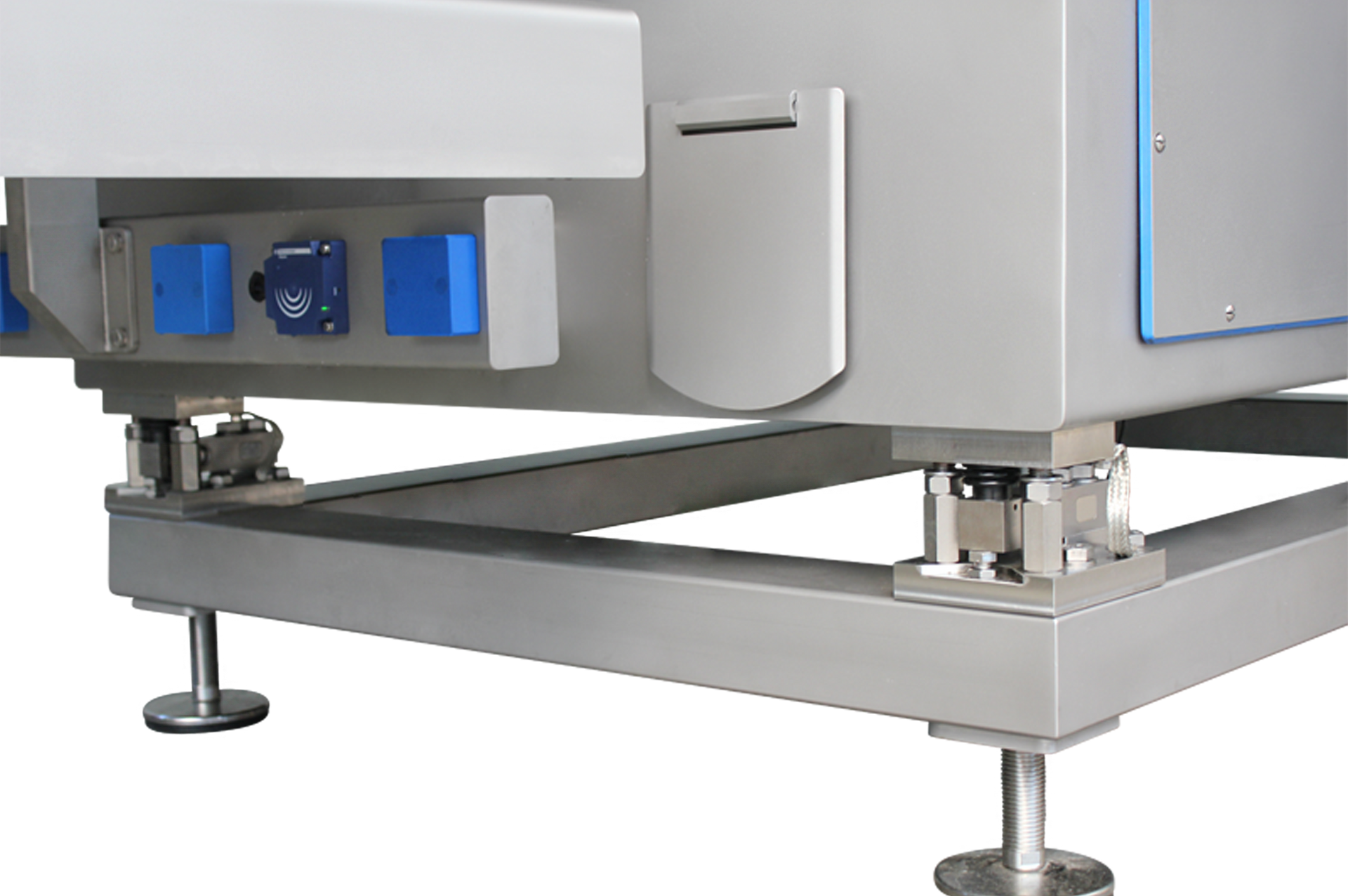

Reliability and customization are at the core of every BAK Food Equipment system. All mixers are constructed entirely from industrial-grade stainless steel, providing exceptional durability and a long lifespan even in the most demanding production environments. Our advanced programmable control panels allow operators to create and store up to 100 custom programs, adjusting variables such as shaft speed, direction, and vacuum level for precise process control. For added convenience and efficiency, our systems are designed with hydraulic unloading, easy-clean features, and options like temperature monitoring, jacketed bowls for heating or cooling, and integrated loading systems. BAK’s U.S.-based service and support team, located in Burr Ridge, IL, ensures responsive assistance, spare parts availability, and expert guidance throughout the life of your equipment. Our commitment to sanitation efficiency, operator safety, and long-term performance makes BAK Food Equipment a trusted partner for food processors seeking reliable, high-performance solutions.

Contact our team to learn how an intermeshing Z-type mixer can improve your production performance.

Intermeshing Z-Type Shaft Mixer FAQs

What is an intermeshing Z-type shaft mixer used for?

Intermeshing Z-type shaft mixers are designed for intensive mixing of high density or sticky products. They are commonly used for applications such as meat fillings, dough, and confectionery blends that require high torque and consistent results.

What’s the benefit of vacuum mixing?

Vacuum mixing removes air from the batch, which enhances protein extraction, improves product density, and ensures uniform flavor distribution. By eliminating air, vacuum mixing also reduces oxidation, resulting in better color retention and longer shelf life for the final product.

Can the Z-type mixers handle both meat and bakery products?

Yes, Z-type mixers are versatile and can process both protein-based mixtures and bakery or confectionery products. Features like variable speed control and programmable settings allow operators to tailor the mixing process to different product types, making these mixers suitable for a wide range of food processing applications.

How does the hydraulic unloading system work?

The hydraulic unloading system automates the process of emptying the mixer. The mixing bowl tilts automatically via a hydraulic lift, allowing for quick and complete discharge of the product. This reduces manual labor, speeds up production, and ensures minimal product loss during unloading.

What optional features are available?

Optional features for intermeshing Z-type shaft mixers include temperature monitoring, jacketed heating or cooling, load cells for precise batch measurement, and automated water dosing systems. These options enhance process control, product consistency, and operational efficiency, allowing the mixer to be customized for specific production needs.