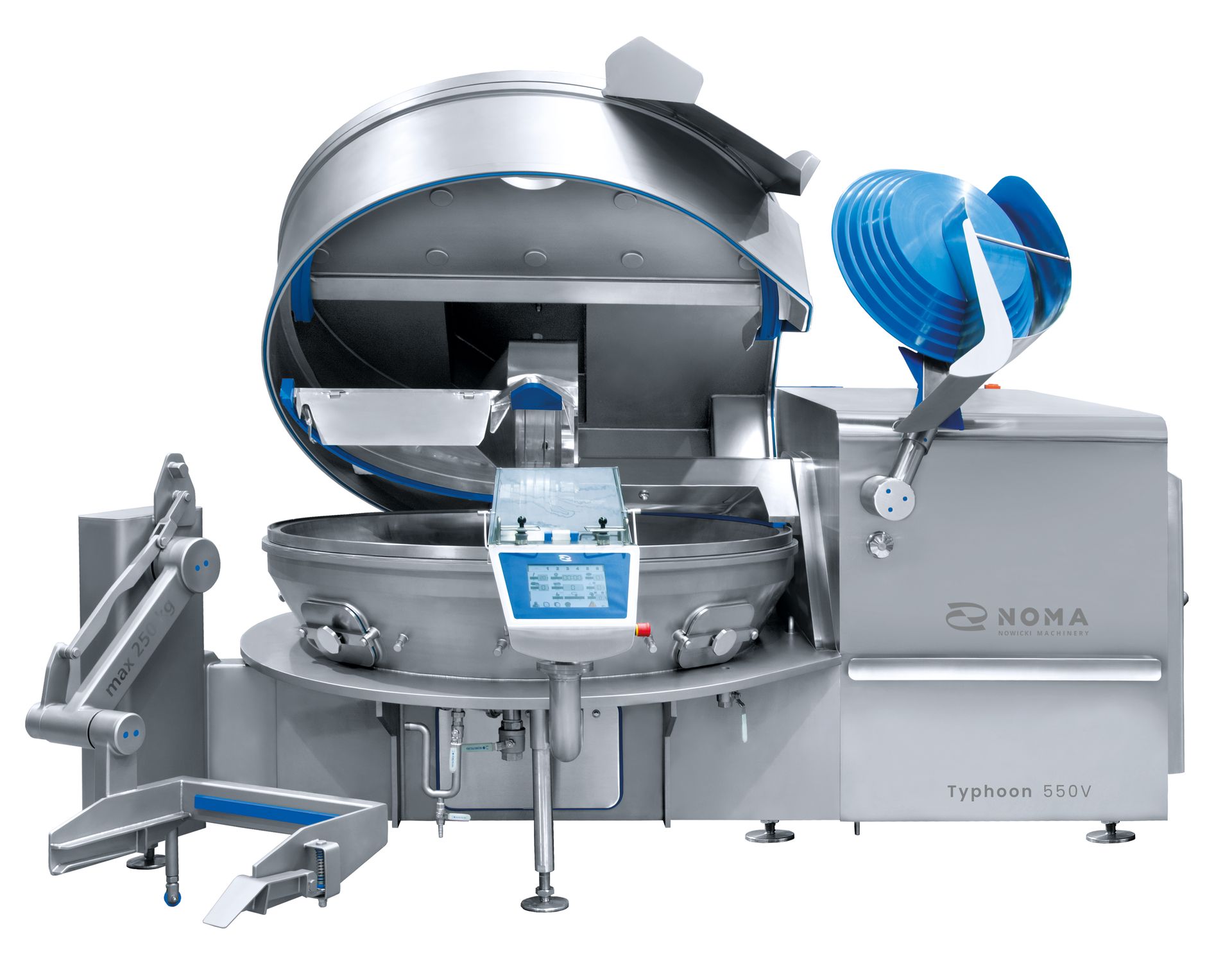

Series KN V

High-Speed Vacuum Bowl Cutters for Precision & Efficiency

Bowl Volume

125-750

Liters

Max Capacity

220-1325

Lbs

- High-Performance and Versatile Design:

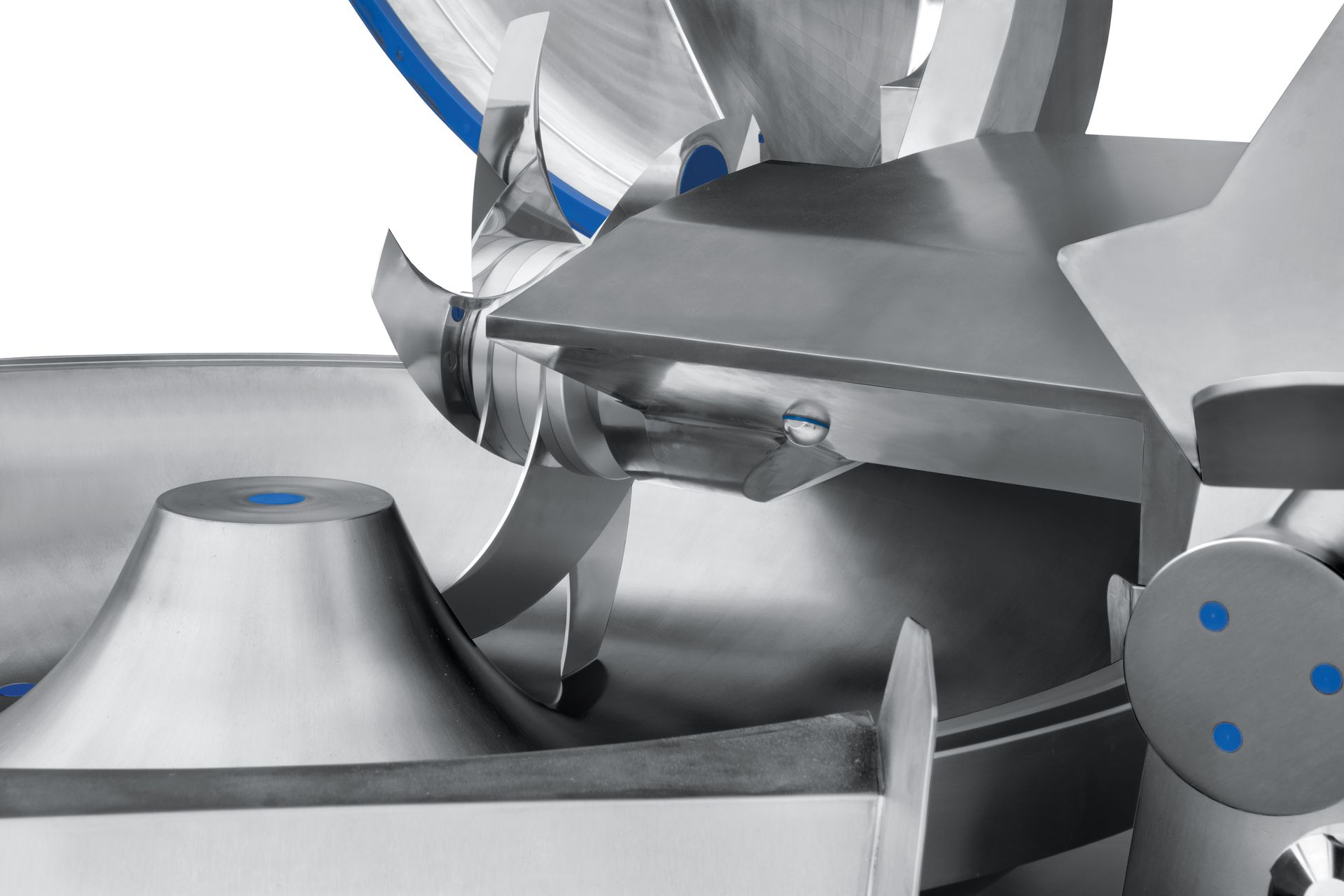

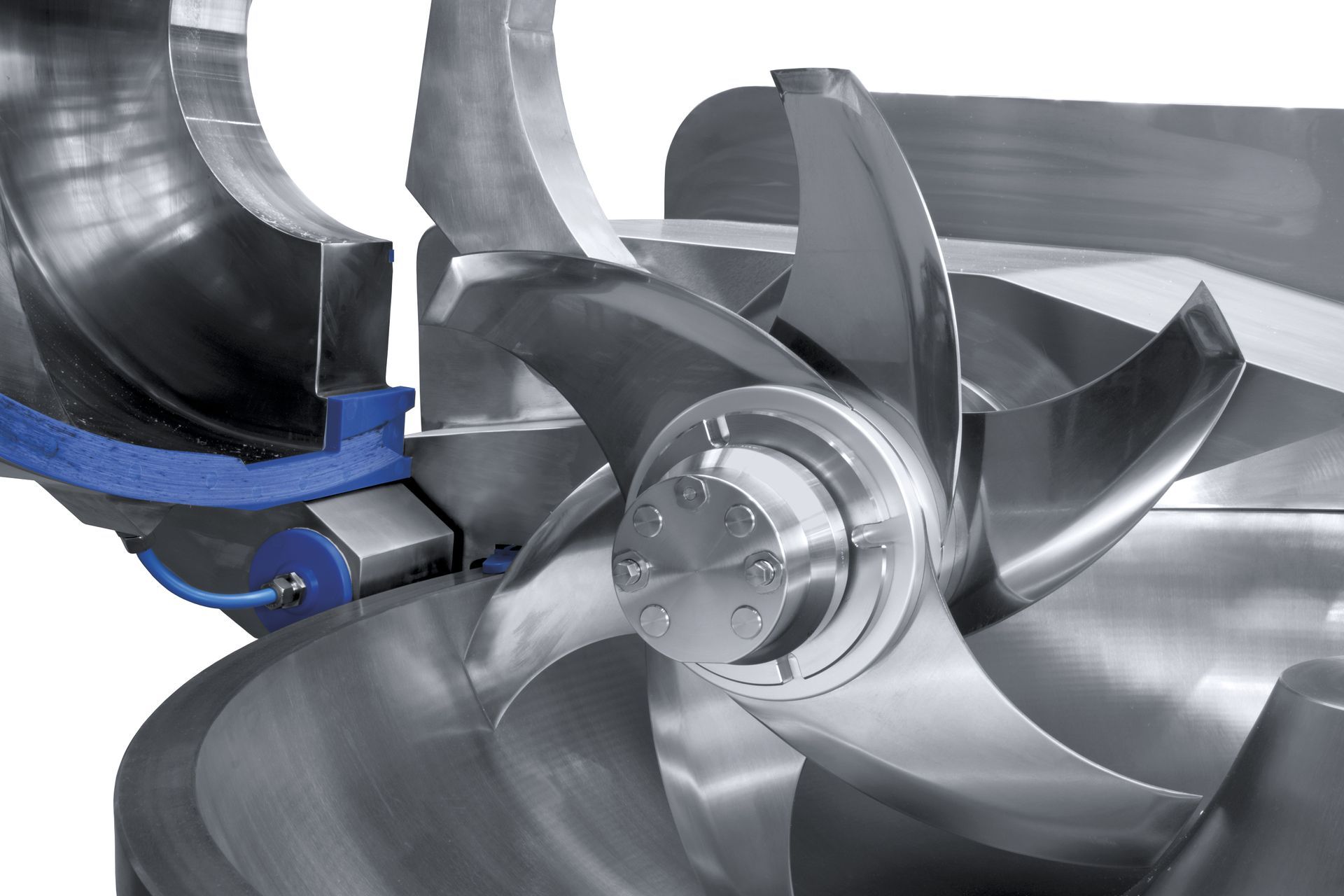

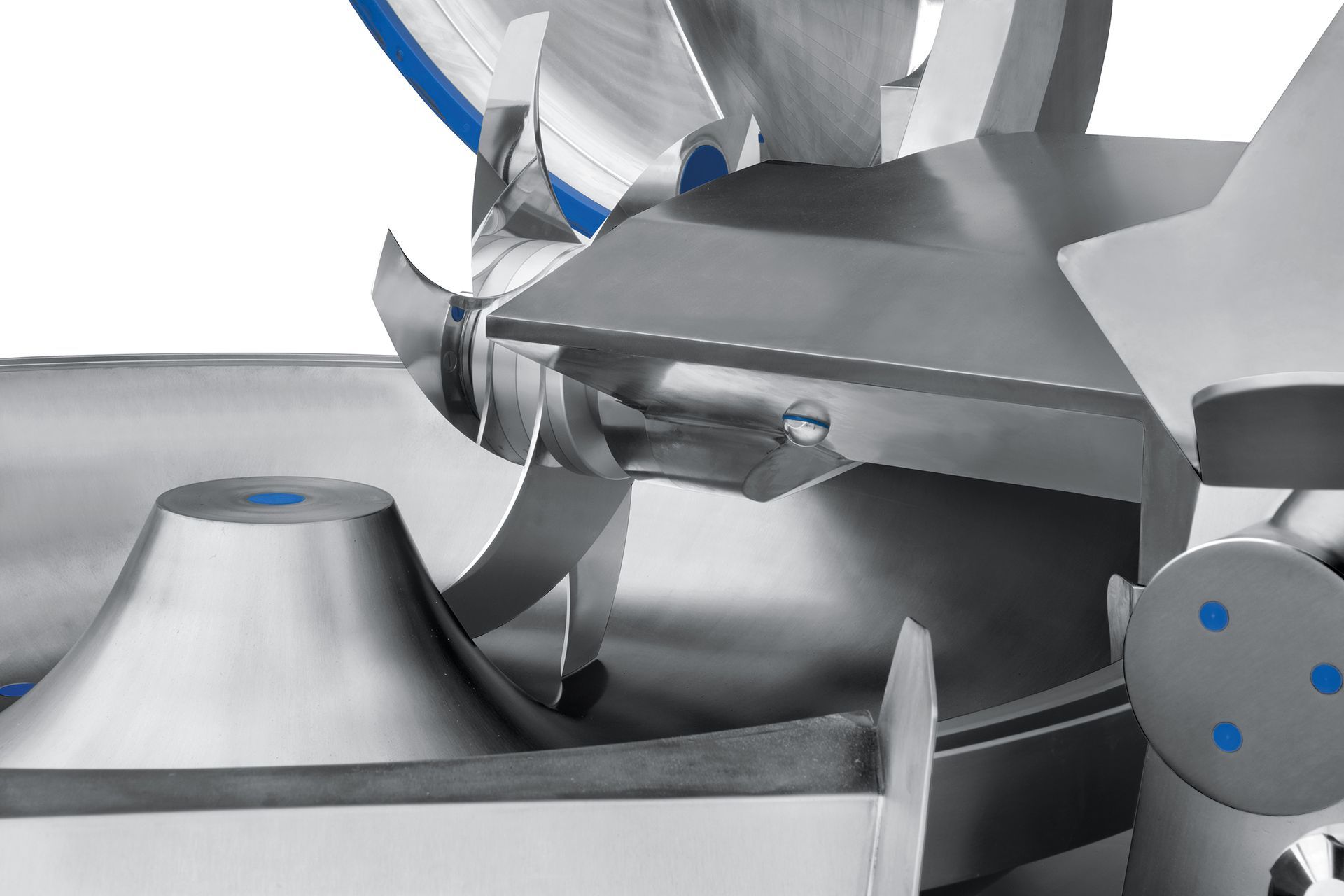

Features an optimized cutting chamber and an advanced knife head rotating at high speeds, allowing for efficient emulsification and mixing while maintaining high production output per hour.

- Precise Variable Control:

Easily adjust all cutting parameters such as cutterhead rotation speed, bowl rotation speed, vacuum level, and temperature. The machine is capable of operating at any setting within its full range, ensuring optimal performance for your specific needs.

- Continuous Vacuum Ability:

Equipped with continuous vacuum capabilities to increase yield and enhance product quality and consistency during processing.

- Hydraulic Operation: Features hydraulically operated front and back covers for the bowl, along with hydraulic loading and unloading systems.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

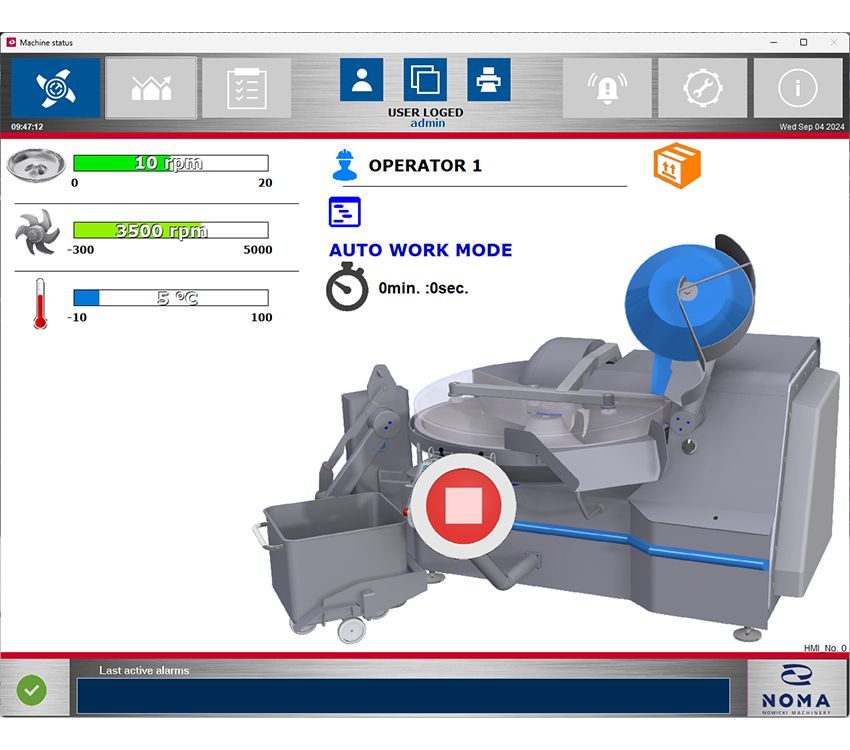

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 40 custom programs by adjusting variables such as cutterhead rotation speed, bowl rotation speed, vacuum level, and temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

NOMA High-Speed Vacuum Bowl Cutters are designed for producing homogenized meats, fat emulsions, and a wide range of meat fillings, including hot dogs, sausages, and salami. Their versatility makes them valuable across multiple industries, including red meat, poultry, fish processing, confectionery, fruit and vegetable production, ready meals, and pet food. These cutters ensure precise, high-quality results for a variety of products, making them essential in both large-scale and specialized production environments.

Farm-to-Retail Meat Processor

“Before our BAK Bowl Cutter, we were forcing hot dogs and emulsified products through grinders and mixers that just weren’t built for that job, and meanwhile good beef and pork trim was piling up or walking out the door as giveaway. Once we upgraded with BAK Food Equipment’s KN 125 HL bowl chopper with auto-load/unload, everything changed: mixing and emulsifying happened in one machine, emulsions became consistent, and we could finally build a full shelf—hot dogs, brats, cheese brats, and specialty sausages with real inclusions. Labor stopped getting burned on manual loading, trim turned into new SKUs instead of waste, and the retail case started selling itself. We even picked up a modest but profitable wholesale stream.” – Leadership Team, Midwest processor

You Might Also Like

Introduction to Vacuum Bowl Cutters

What is a vacuum bowl cutter, and how does it work?

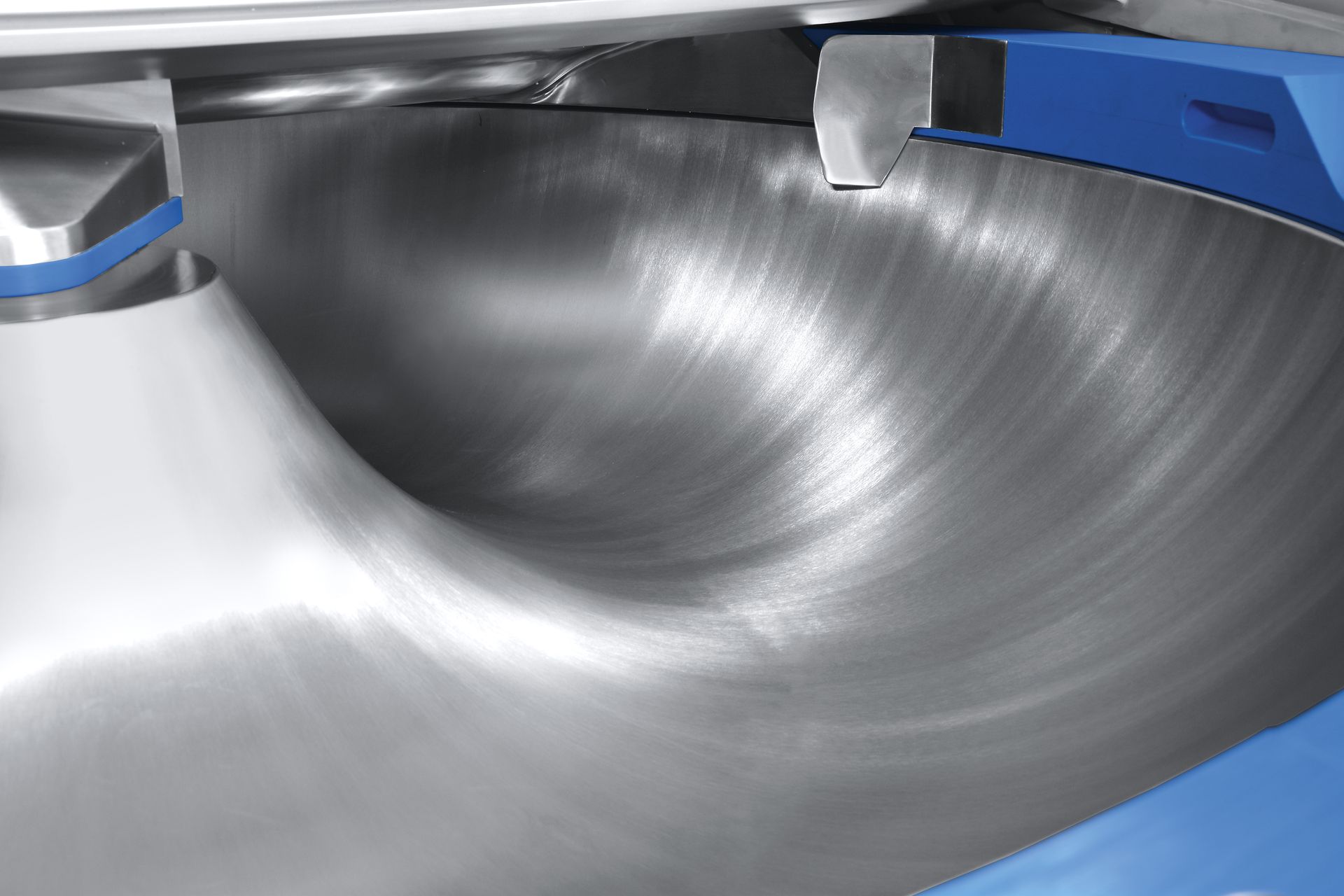

A vacuum bowl cutter is a high-speed mixing, chopping and emulsifying machine designed for processing a wide range of food products, including meat, fish, poultry, and plant-based proteins. At its core, the machine consists of a large, rotating bowl and a set of rapidly spinning knives. The product is placed in the bowl, where the knives chop, mix, and emulsify the ingredients to achieve the desired texture and consistency. What sets vacuum bowl cutters apart from traditional bowl choppers is their ability to operate under a controlled vacuum environment. This vacuum function removes air from the product during processing, which results in a denser, more consistent product with a more stable color, and a higher yield. By minimizing oxidation, the final product is more shelf-stable.

Why are vacuum bowl cutters essential in modern meat and food processing?

Vacuum bowl cutters have become indispensable in today’s food processing industry due to their versatility, efficiency, and ability to deliver consistent, high-quality results. By reducing air incorporation, these machines help maintain product integrity, extend shelf life, and improve protein extraction, which leads to higher yields and better water-binding capacity. Beyond meat, vacuum bowl cutters are also used in the production of plant-based proteins, seafood, confectionery, ready meals, pet food, and soups, sauces, and oils making them a versatile solution for a variety of applications. Their ability to handle diverse ingredients and recipes makes them essential for processors seeking to meet evolving consumer demands for quality, consistency, and innovation.

What sets the Series KN V models apart?

The Series KN V high-speed vacuum bowl cutters from BAK Food Equipment stand out due to their advanced engineering and user-focused features. These machines are equipped with an optimized cutting chamber and a high-performance knife head capable of reaching speeds up to 5,000 RPM, ensuring efficient emulsification and mixing. Operators benefit from precise variable controls, allowing them to adjust cutterhead and bowl rotation speeds and direction, vacuum levels, and temperature to suit specific processing requirements. Processors can also rotate the knives and bowl in the opposite direction for efficient mixing without cutting. The continuous vacuum capability ensures consistent product quality and maximizes yield throughout the production cycle. Hydraulic operation of the bowl covers and loading/unloading systems streamlines workflow and enhances safety. Built entirely from stainless steel, the Series KN V models are designed for durability and easy cleaning, making them ideal for demanding industrial environments. The programmable control panel, featuring an intuitive touch screen, allows users to create and store up to 40 custom programs, further enhancing flexibility and repeatability. These features, combined with their ability to process a wide range of products, position the Series KN V vacuum bowl cutters as a leading choice for modern food processors seeking reliability, efficiency, and superior product quality.

Key Features of the Series KN V Vacuum Bowl Cutters

What are the defining features of Series KN V models?

The Series KN V vacuum bowl cutters from BAK Food Equipment are engineered for high performance and versatility in demanding food processing environments. These industrial bowl cutters are available in a range of bowl volumes from 125 to 750 liters, accommodating maximum capacities from 220 to 1,323 pounds. At the heart of each model is an optimized cutting chamber paired with an advanced knife head capable of reaching speeds up to 5,000 RPM, ensuring efficient emulsification and chopping. The robust, all-stainless steel construction guarantees long-term durability and supports rigorous hygiene standards, making these machines ideal for continuous operation in meat, poultry, fish, and other food processing applications.

How do these features enhance performance and consistency?

The Series KN V models are equipped with a suite of advanced features that directly contribute to superior product quality and operational efficiency. Precise variable controls allow operators to adjust cutterhead and bowl rotation speeds, vacuum levels, and processing temperatures, enabling fine-tuned customization for each recipe or product type. The continuous vacuum system is a standout feature, significantly improving protein binding, color retention, and extending product shelf life by minimizing oxidation during processing. Hydraulic operation of the bowl covers and integrated loading/unloading systems streamline workflow and reduce manual labor, while the programmable touch screen control panel allows storage of up to 40 custom programs for repeatable, consistent results. Easy-to-clean design and straightforward maintenance further ensure that these vacuum food processors deliver reliable, hygienic performance batch after batch, supporting the highest standards in modern food production.

Technical Specifications of Series KN V

What sizes and capacities are available?

The Series KN V high-speed vacuum bowl cutters from BAK Food Equipment are available in a range of sizes to accommodate diverse production needs. The models include bowl volumes of 125, 200, 330, 550, and 750 liters. This translates to a maximum capacity range from 220 lbs (KN 125 V) up to 1,323 lbs (KN 750 V), making these machines suitable for from independent to large-scale processing operations. Each model is engineered for industrial use, with robust stainless steel construction ensuring durability and longevity in demanding environments. The obtainable vacuum level across all models is up to 90%, supporting superior product quality and consistency.

How do different models fit varying production scales?

The KN V series offers a scalable solution for processors of all sizes. The KN 125 V and KN 200 V are ideal for smaller or specialized production lines, with compact footprints and capacities of 220 lbs and 353 lbs, respectively. For medium to large-scale operations, the KN 330 V (582 lbs), KN 550 V (970 lbs), and KN 750 V (1,323 lbs) provide increased throughput and efficiency. Depending on the model, cutterhead speeds range from 200 to 5,000 RPM for emulsification and 100 to 300 RPM for mixing—allowing precise control over product texture and consistency. The machines are equipped with hydraulic loading and unloading systems, and their dimensions scale with capacity, ensuring that processors can select the right fit for their available space and production requirements. These vacuum cutter specs make the KN V series a versatile choice for applications in meat, poultry, fish, and other food processing sectors, supporting both high-volume and specialty product lines.

Applications of Vacuum Bowl Cutters

What products can be made with vacuum bowl cutters?

Vacuum bowl cutters are renowned for their versatility and precision, making them indispensable in the production of a wide array of food products. In the meat industry, these machines are essential for creating finely homogenized and emulsified products such as hot dogs, sausages, salami, pâtés, and various meat emulsions. Their ability to precisely control cutting parameters and maintain a consistent vacuum environment ensures superior texture and uniformity in every batch.

Beyond traditional meat applications, vacuum bowl cutters are also widely used in seafood processing. They are ideal for producing salmon blends, fish cakes, and surimi, where achieving a smooth, cohesive mixture is critical for product quality. In the poultry sector, these machines efficiently process chicken and turkey blends for nuggets, and other value-added products, delivering consistent results at high production volumes.

The versatility of vacuum bowl cutters extends to other industries as well. In confectionery, they are used for preparing smooth fillings, while in fruit and vegetable processing, they create pastes and purees with uniform consistency. Ready meal manufacturers rely on these machines for chopping, blending, and emulsifying various components, and the pet food industry benefits from their ability to process a wide range of protein and vegetable blends to exacting standards.

Which industries benefit most from vacuum bowl cutters?

Industries that demand high levels of product consistency, texture, and quality benefit most from vacuum bowl cutters. The meat processing sector, including sausage production and meat emulsification, is a primary user, leveraging these machines to produce everything from traditional sausages to innovative meat snacks. Seafood processors utilize fish processing equipment such as vacuum bowl cutters to create premium fish products with desirable mouthfeel and appearance.

Poultry processors also gain significant advantages, as vacuum bowl cutters enable the efficient production of nuggets, and other formed poultry products. The pet food processing machinery sector relies on these machines for their ability to handle diverse ingredients and deliver uniform, high-quality blends suitable for a variety of pet food formulations.

Additionally, manufacturers in the confectionery, fruit and vegetable, and ready meal industries benefit from the precision and flexibility of vacuum bowl cutters. Their programmable controls, high-speed operation, and robust construction make them suitable for both large-scale industrial production and specialized applications, ensuring consistent results across multiple markets.

Optional Systems & Customization

What options are available with the Series KN V?

The Series KN V high-speed vacuum bowl cutters from BAK Food Equipment are engineered for versatility and can be tailored to meet the specific needs of diverse food processing operations. To enhance their performance and adapt to specialized production requirements, several optional systems are available:

- Cooking System: This add-on enables thermal processing directly inside the cutter, allowing for the cooking of products during the emulsification or mixing process. This integration streamlines production by reducing the need for separate cooking equipment and helps maintain product consistency and quality.

- Cooling System: Maintaining low temperatures during emulsification is critical for many meat and protein products. The cooling system option ensures that the bowl and its contents remain at optimal temperatures, which is essential for preserving texture, color, and food safety throughout processing.

- Water Dosage System: Precision in ingredient addition is vital for consistent product quality. The water dosage system provides accurate and automated water addition, improving batch-to-batch consistency and supporting recipe control for a wide range of applications.

- SCADA Monitoring System: For processors seeking advanced automation and data-driven process management, the SCADA monitoring system offers real-time data tracking, process automation, and optimization. This system supports compliance, traceability, and efficiency improvements by integrating seamlessly with automated food processing systems.

How do add-ons expand functionality?

Each optional system is designed to expand the core capabilities of the Series KN V vacuum bowl cutter, transforming it from a high-performance cutting machine into a fully integrated processing solution. The cooking and cooling systems allow for precise thermal management, and the water dosage system automates a critical step in recipe management, reducing manual intervention and the risk of error. The SCADA monitoring system elevates the cutter into the realm of smart manufacturing, enabling operators to monitor, control, and optimize production in real time. These custom bowl cutter options ensure that the Series KN V can be configured to meet the evolving demands of modern food production, supporting both flexibility and efficiency in automated food processing systems and SCADA food monitoring environments.

Benefits of High-Speed Vacuum Bowl Cutters

What advantages do vacuum bowl cutters offer over traditional equipment?

For a range of products, vacuum bowl cutters are often used over a traditional bowl cutter. One of the primary advantages is their ability to operate under vacuum conditions, which minimizes oxidation during processing. This results in more dense final product with a longer shelf-life, improved color retention, enhanced protein binding, and superior emulsification—key factors for certain sausages, deli meats, and hot dogs. The advanced knife head, rotating at high speeds within an optimized cutting chamber, ensures thorough mixing and emulsification, producing a finer, more uniform texture compared to less advanced machines. Additionally, the robust stainless steel construction and hydraulic operation of these machines guarantee durability and reliable performance in demanding industrial environments.

How do they improve efficiency, quality, and ROI?

Efficiency: High-speed vacuum bowl cutters are engineered for high output per hour, making them ideal for large-scale production. Their continuous vacuum capability and programmable controls allow for rapid, repeatable processing with minimal manual intervention. Hydraulic loading and unloading systems further reduce labor requirements and speed up batch turnover, while easy-to-clean designs minimize downtime for maintenance.

Quality: By processing under vacuum, these machines significantly improve the texture, color, and protein binding of the final product. The precise variable control over cutterhead and bowl rotation speeds, vacuum level, and temperature ensures optimal results for a wide range of recipes. This level of control is especially important for meat emulsification, where consistency and product integrity are critical.

Consistency: The advanced programmable control panel allows operators to create and store up to 40 custom programs, ensuring repeatable results across batches. This automation in food production not only enhances consistency but also reduces the risk of human error.

Versatility: High-speed vacuum bowl cutters are suitable for a diverse array of food categories, including red meat, poultry, fish, confectionery, fruit and vegetable products, ready meals, and pet food. Their adaptability makes them a valuable asset for processors looking to expand their product lines or improve existing offerings.

ROI: The combination of higher yields, longer shelf life, and reduced waste translates directly into a stronger return on investment (ROI) in food machinery. By improving product quality and processing efficiency, these machines help manufacturers meet market demands while controlling costs and maximizing profitability.

Partner with BAK for Cutting Solutions

Why choose BAK for vacuum bowl cutters?

BAK Food Equipment stands out as a trusted vacuum cutter partner for processors seeking advanced, reliable, and hygienic cutting solutions. Our high-speed vacuum bowl cutters are engineered for exceptional performance, featuring an optimized cutting chamber and advanced knife head that deliver efficient emulsification and mixing at high production outputs. Built entirely from stainless steel, our equipment is designed for durability and long-lasting operation in demanding industrial environments. The intuitive, programmable control panel allows operators to create and store up to 40 custom programs, ensuring precise control over every batch. With continuous vacuum capabilities, our machines enhance product yield and consistency, making them ideal for a wide range of applications, from meat and poultry to seafood, plant-based, and pet food products.

How does BAK support long-term production success?

At BAK Food Equipment, we are committed to supporting your production success well beyond the initial purchase. Our team brings deep expertise in supplying advanced, durable, and hygienic equipment tailored to the unique needs of each processor. We offer comprehensive support for a variety of industries, including meat, poultry, seafood, plant-based, and pet food, ensuring that our solutions are both innovative and scalable as your business grows. Our vacuum bowl cutters are thoughtfully designed for easy cleaning and maintenance, minimizing downtime and maximizing operational efficiency. Whether you require standard or customized food cutting solutions, BAK’s commitment to innovation and customer partnership ensures you have the right equipment and support for long-term success.

FAQ: High-Speed Vacuum Bowl Cutters

What is a vacuum bowl cutter?

A vacuum bowl cutter is a specialized industrial food processing machine designed to chop, mix, and emulsify ingredients such as meat, poultry, seafood, and plant-based proteins under a controlled vacuum environment. By operating under vacuum, these machines enhance protein binding, improve texture, and preserve the natural color of the product, resulting in a higher-quality finished product.

What are vacuum bowl cutters used for?

Vacuum bowl cutters are widely used in the production of a variety of food products, including sausages, hot dogs, salami, pâtés, deli meats, fish cakes, surimi, plant-based protein products, confectionery, and pet food. Their ability to finely chop and emulsify ingredients makes them essential for creating uniform textures and stable emulsions, which are critical in processed meat and alternative protein industries.

How does the vacuum function improve product quality?

The vacuum function in these bowl cutters plays a crucial role in product quality. Processing under vacuum enhances protein extraction, which is vital for binding and texture. It also prevents oxidation, helping to maintain the natural color and flavor of the product. Additionally, the vacuum environment increases yield and extends shelf life by reducing the presence of air, which can cause spoilage and discoloration.

What makes the Series KN V different from standard bowl cutters?

The Series KN V stands out due to its high-speed knife rotation—up to 5,000 RPM—allowing for rapid and efficient emulsification and mixing. It features an advanced programmable control panel, enabling operators to store up to 40 custom recipes and precisely control variables such as cutterhead speed, bowl speed, vacuum level, and temperature. The Series KN V also offers continuous vacuum capability and hydraulic systems for loading, unloading, and cover operation, ensuring both efficiency and operator safety. Its robust stainless steel construction ensures durability and easy cleaning, making it ideal for demanding industrial environments.

What capacities are available for the Series KN V?

The Series KN V is available in a range of capacities to suit different production needs. Models include bowl volumes from 125 liters (220 lbs capacity) up to 750 liters (1325 lbs capacity). This range makes the Series KN V suitable for both specialized, small-batch production and large-scale industrial operations.

What industries use vacuum bowl cutters?

Vacuum bowl cutters are utilized across a broad spectrum of industries, including red meat, poultry, seafood, plant-based protein, confectionery, fruit and vegetable processing, ready meals, and pet food. Their versatility and ability to deliver consistent, high-quality results make them indispensable in both traditional and emerging food processing sectors.

What optional systems are available for the Series KN V?

To further enhance functionality, the Series KN V can be equipped with optional systems such as cooking, cooling, water dosage, and SCADA monitoring. These add-ons allow processors to expand the machine’s capabilities and seamlessly integrate it into automated production lines, supporting greater flexibility and process control.

How easy is it to maintain and clean vacuum bowl cutters?

The Series KN V is engineered for straightforward maintenance and cleaning. Its stainless steel construction, smooth surfaces, and hydraulically operated covers provide easy access to all areas, ensuring quick and thorough cleaning. This design not only supports efficient maintenance routines but also helps processors meet stringent food safety standards.