Semi-Continuous Smoking/Chilling System

Total Capacity

3100 - 12,500

Lbs.

Trolleys

2 - 16

*Our smoke chambers offer flexibility in size, smoke type, and layout, allowing you to tailor the system to meet the specific needs of your production.

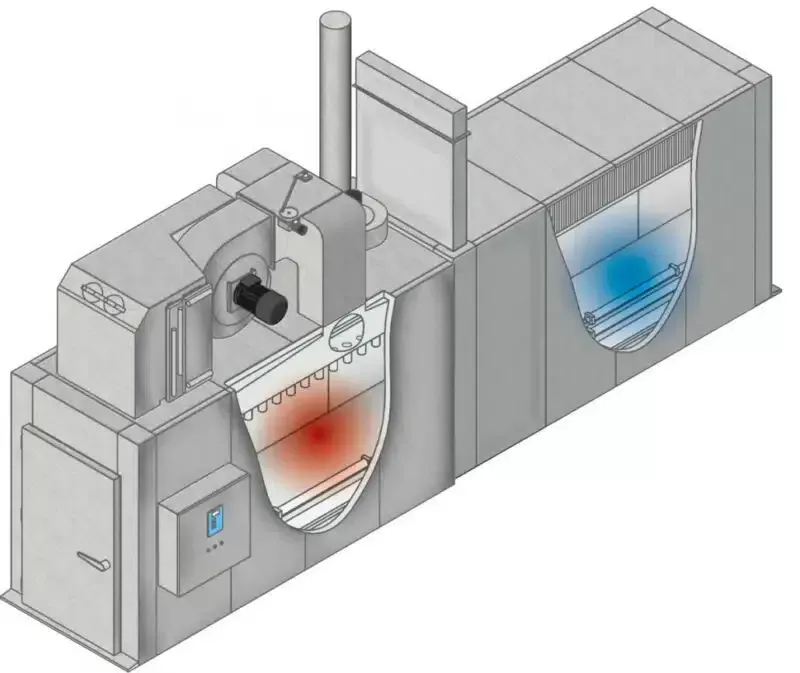

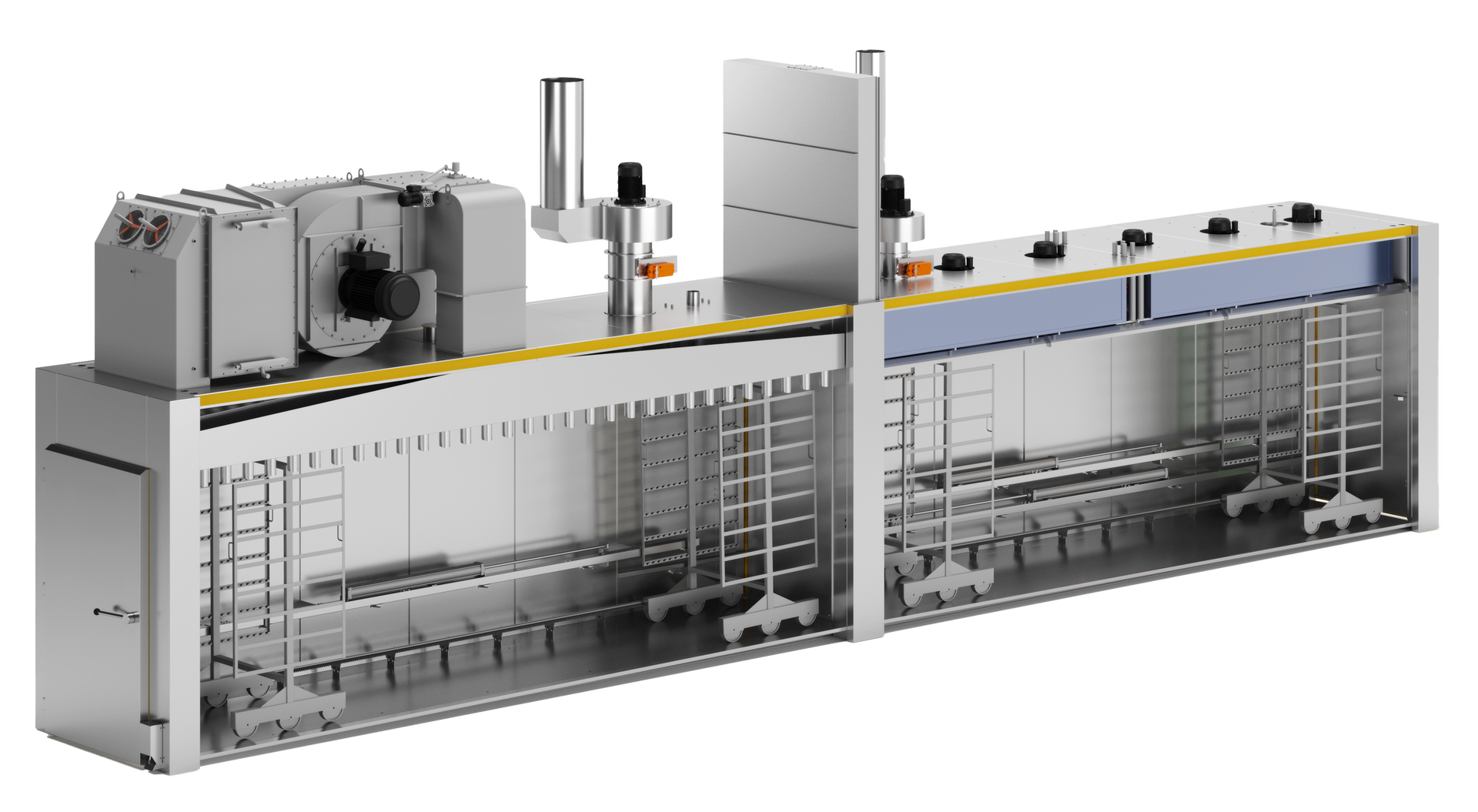

- Smoking/Chilling System with Automatic Transportation: Our all-in-one system features a smoke chamber and a cooling chamber connected by a rail transportation system. This allows a highly efficient transition from the smoking process to the cooling process.

- Alternating Flap System: The unique alternating flap system continuously changes the air circulation around the products in the chamber, ensuring an even smoking and chilling process.

- Hot, Cold, or Hot/Cold Smoke Capabilities: Can be equipped to handle hot smoke, cold smoke, or a both, making it suitable for a wide range of smoked products, from bacon to smoked salmon.

- Durable, Fully Welded Chamber: The fully welded chamber provides a significant advantage in the smoking process by ensuring no leakage over time. This design maximizes durability and enhances the overall smoking performance.

Why Choose BAK

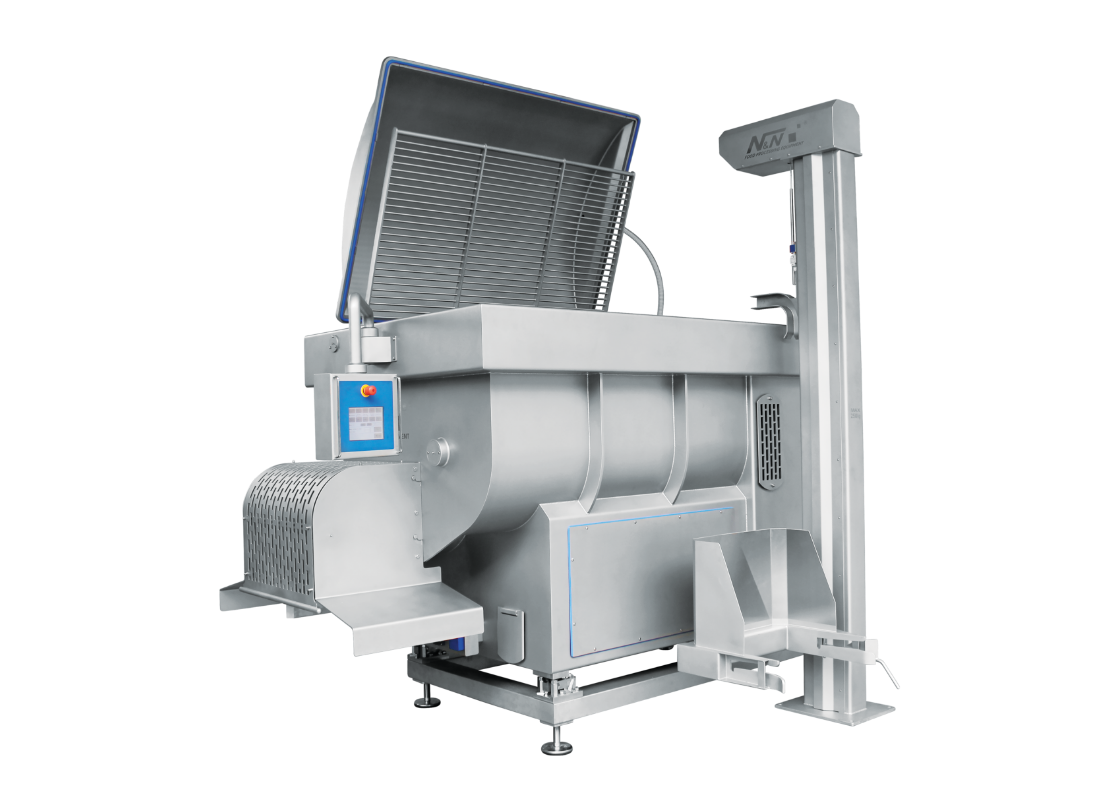

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 99 custom programs by adjusting variables such as vacuum level, rotation speed, tumbling time, and temperature.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. Inspection hatches are strategically placed for quick, convenient access.

Technical Information

Applications

Protech Semi-Continuous Smoking Chambers are designed for a wide range of food processing applications, including meats, poultry, seafood, and more. Ideal for both hot and cold smoking, these chambers ensure consistent flavor, color, and texture across all products. Our chambers offer precise control over temperature, smoke levels, and humidity to deliver premium results at high production volumes.

Large Bacon Producer

"Before we introduced BAK’s automated spiral system, our bacon production rose and fell with Monday’s workforce. Now that we’ve streamlined the entire process—smoking, cooking, and chilling in a single continuous system—we’ve not only stabilized our output, but we’re producing better bacon than ever. It’s been a complete game-changer.“ – Leadership team

You Might Also Like

Introduction to Semi-Continuous Smoking and Chilling Systems

What is a semi-continuous smoking chilling system?

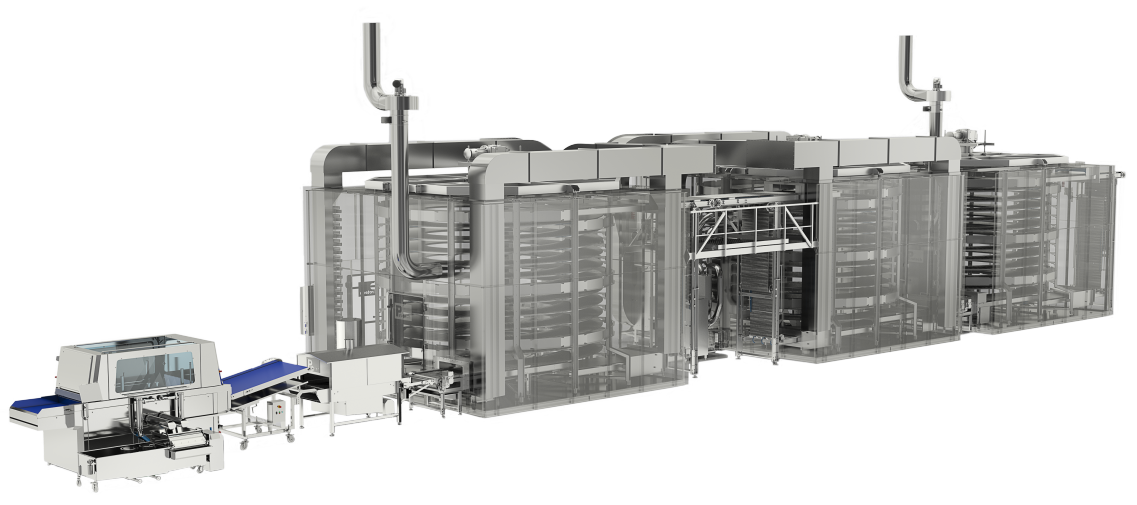

A semi-continuous smoking chilling system is an integrated solution designed for high-capacity, automated food processing. At its core, this system combines a smoke chamber and a chilling chamber, which are directly connected by an automatic rail transportation system. This design allows for a seamless transition from the smoking process to the chilling process, eliminating the need for manual handling and significantly reducing downtime between production cycles. The system is engineered to handle large volumes—ranging from 3,100 to 12,500 pounds per cycle—making it ideal for industrial-scale operations. With flexible configurations, the system can be tailored to specific production needs, including the type of smoke (hot, cold, or both), chamber size, and layout.

How does it differ from traditional batch smokehouses?

Unlike traditional batch smokehouses, which require manual transfer of products between separate smoking and chilling chambers, semi-continuous systems automate this process. The automatic rail transport system moves trolleys loaded with product directly from the smoking chamber to the chilling chamber, streamlining workflow and minimizing labor requirements. Additionally, the alternating flap system within the chambers ensures continuous and even air circulation, resulting in consistent smoking and chilling across all products. The fully welded, stainless steel construction of the chambers prevents leakage and enhances durability, while advanced programmable control panels allow operators to store and execute up to 99 custom programs for precise control over variables such as temperature, smoke level, and humidity. This level of automation and control is a significant advancement over traditional batch systems, which are more labor-intensive and less consistent in output.

What types of processors benefit from semi-continuous systems?

Semi-continuous smoking and chilling systems are particularly beneficial for processors in the meat, poultry, and seafood industries who require consistent product quality at high production volumes. These systems are ideal for facilities that need to maintain uniform color, flavor, and texture across large batches, such as those producing bacon, smoked salmon, sausages, or deli meats. The ability to handle both hot and cold smoking processes in a single, integrated system makes it versatile for a wide range of applications. Industrial processors seeking to improve efficiency, reduce labor costs, and ensure food safety through automated handling and precise process control will find significant value in adopting semi-continuous smoking and chilling technology. The system’s robust construction and easy maintenance further support long-term, reliable operation in demanding production environments.

By integrating advanced features such as automated transportation, programmable controls, and durable construction, semi-continuous smoking chilling systems represent a modern solution for industrial smoking and chilling needs, supporting semi-continuous food processing and consistent product quality.

Benefits of a Semi-Continuous Smoking/Chilling System

What advantages do semi-continuous systems provide over batch smokehouses?

Semi-continuous smoking/chilling systems offer significant advantages over traditional batch smokehouses, particularly in terms of efficiency, product uniformity, and operational flexibility. Unlike batch systems, which require manual transfer and separate processing steps, a semi-continuous system integrates the smoking and chilling processes through an automatic rail transportation system. This seamless transition between chambers reduces downtime and labor requirements, allowing for higher throughput and more streamlined production. The system’s flexible design accommodates a wide range of product types and volumes, making it ideal for processors who need to adapt to changing production demands without sacrificing quality or efficiency.

How do they improve consistency, throughput, and hygiene?

Consistency is a hallmark of semi-continuous systems, largely due to the unique alternating flap system that continuously changes air circulation around the products. This ensures even heat distribution and uniform exposure to smoke and cooling air, resulting in consistent flavor, color, and texture across every batch. The precise control over temperature, humidity, and smoke levels—managed through an advanced programmable control panel—enables operators to fine-tune the process for optimal results, whether hot or cold smoking is required.

Throughput is enhanced by the system’s ability to handle large capacities (from 3,100 to 12,500 lbs. per cycle) and by minimizing manual handling. Automated transitions between smoking and chilling not only speed up the process but also reduce the risk of cross-contamination, directly supporting food safety in smoking operations. The fully welded, stainless steel construction and thoughtfully placed inspection hatches make cleaning and maintenance straightforward, further supporting hygiene and compliance with food safety standards.

Applications Across Food Processing

What industries and products are suited for semi-continuous systems?

Semi-continuous smoking and chilling systems are engineered to meet the diverse needs of several food processing industries. Meat and poultry processors benefit significantly from these systems, as they are designed to deliver consistent smoked color and yield across large batches. The ability to precisely control temperature, smoke levels, and humidity ensures that products such as sausages, bacon, ham, and jerky achieve uniform flavor and appearance, which is critical for brand consistency and customer satisfaction.

Seafood producers also find semi-continuous systems ideal, particularly when processing delicate products like smoked salmon or other fish. The advanced programmable control panel allows for fine-tuned adjustments, ensuring that seafood is smoked and chilled at optimal conditions to preserve texture and prevent overcooking or drying.

Pet food manufacturers are increasingly turning to semi-continuous smoking and chilling systems to ensure uniform drying and enhanced safety. The even air circulation provided by the alternating flap system helps achieve consistent moisture levels, which is vital for shelf stability and product safety in pet food processing.

Why is it ideal for high-volume processors?

Semi-continuous smoking and chilling systems are specifically designed for high-volume food processors who require efficiency, consistency, and reliability. The integration of a smoke chamber and cooling chamber, connected by an automatic rail transportation system, streamlines the transition between smoking and chilling. This not only reduces manual handling but also minimizes production downtime, enabling continuous throughput and maximizing productivity.

The robust, fully welded stainless steel construction ensures durability and longevity, even in demanding industrial environments. With capacities ranging from 3,100 to 12,500 pounds and the ability to accommodate up to 16 trolleys, these systems are built to handle large-scale operations. The intuitive touch screen control panel allows operators to store up to 99 custom programs, making it easy to switch between different products or recipes without sacrificing efficiency.

Partner with BAK for Smoking Efficiency

Why choose BAK’s semi-continuous systems?

BAK Food Equipment stands out as an industrial smokehouse supplier by offering semi-continuous smoking and chilling systems that are engineered for both efficiency and flexibility. Our systems are designed to accommodate a wide range of production capacities, from 3,100 to 12,500 pounds, and can be configured with 2 to 16 trolleys to match your specific throughput requirements. The all-in-one design integrates a smoke chamber and a cooling chamber, connected by an automatic rail transportation system, which streamlines the transition from smoking to chilling and maximizes operational efficiency. The unique alternating flap system ensures even air circulation, resulting in consistent product quality across every batch.

How does BAK ensure long-term value and reliability?

BAK’s expertise in automated smoking technology is reflected in every aspect of our semi-continuous systems. Each chamber is fully welded and constructed from industrial-grade stainless steel, providing exceptional durability and preventing leakage over time. This robust construction is complemented by advanced programmable control panels, allowing operators to create and store up to 99 custom programs for precise control over variables such as temperature, smoke levels, and humidity. Our systems are thoughtfully engineered for easy cleaning and maintenance, with strategically placed inspection hatches for quick access. Backed by proven technology and comprehensive engineering support, BAK Food Equipment delivers solutions that offer long-term reliability and value for processors seeking to automate and scale their smoking operations.

Ready to optimize your smoking and chilling process? Contact BAK Food Equipment to discuss your semi-continuous smoking and chilling needs. Our team is ready to help you achieve your capacity goals and integrate automation into your production line.

Semi-Continuous Smoking/Chilling System FAQs

What is a semi-continuous smoking chilling system?

A semi-continuous smoking chilling system is an advanced, automated setup that integrates both smoking and chilling processes within a single production line. The system consists of a smoke chamber and a cooling chamber, which are connected by a rail transportation system. This design allows for seamless movement of products between the smoking and chilling stages, minimizing manual handling and ensuring a highly efficient workflow. The alternating flap system within the chambers continuously changes air circulation, guaranteeing even smoking and chilling for every batch.

What types of foods can be processed with a semi-continuous system?

These systems are engineered to handle a broad range of products, including smoked meats, poultry, fish, sausages, and even pet foods. The flexibility of the semi-continuous smoking chilling system makes it suitable for processors who require uniform smoking and chilling across various product types. Whether you are producing bacon, smoked salmon, or specialty sausages, the system’s precise control over temperature, smoke levels, and humidity ensures consistent flavor, color, and texture.

How does a semi-continuous system improve efficiency?

Efficiency is a hallmark of the semi-continuous smoking chilling system. By automating the transition between smoking and chilling chambers via a rail system, the need for manual product handling is greatly reduced. This not only speeds up production but also helps maintain product integrity and uniformity. The alternating flap system further enhances efficiency by ensuring consistent air circulation, which leads to even smoking and chilling results. Additionally, the fully welded, stainless steel construction and intuitive touch screen controls make cleaning, maintenance, and operation straightforward and reliable, supporting high production volumes with minimal downtime.

Can BAK’s system perform both hot and cold smoking?

Yes, BAK’s semi-continuous smoking chilling system is designed for maximum versatility. It can be configured for hot smoking, cold smoking, or a combination of both, depending on your product requirements. This adaptability allows processors to expand their product offerings and meet diverse market demands without the need for multiple separate systems.

What capacity options are available?

BAK offers a range of models to suit different production needs. The system is available in configurations from 4 to 16 trolleys, with total load capacities ranging from 3,100 to 12,500 lbs. This scalability ensures that both small and large processors can benefit from the efficiency and consistency of a semi-continuous smoking chilling system. For more information on available models and their specifications, visit our Smoked Products Processing Equipment page.