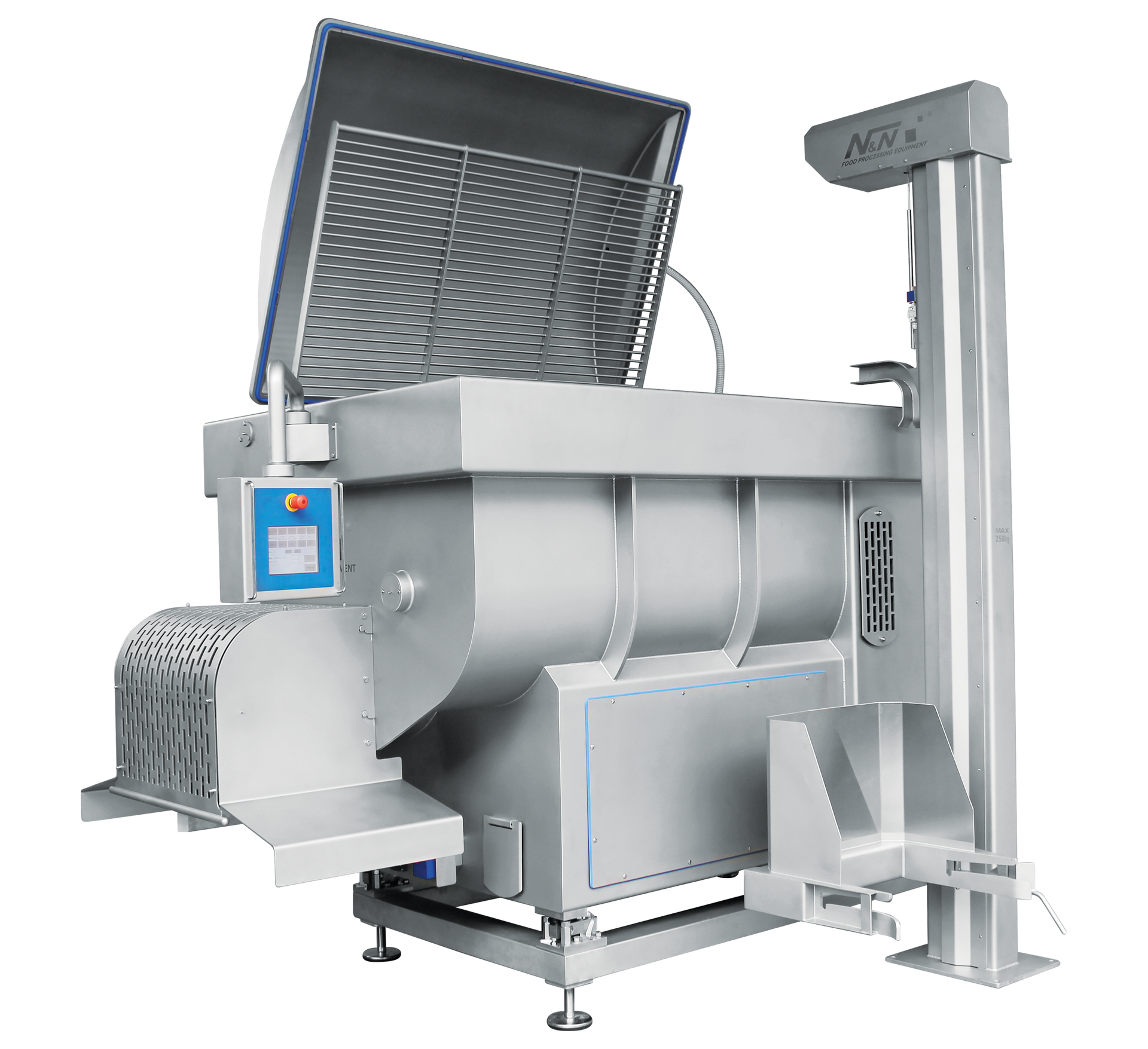

Series MIX S/SV

Series MIX S/SV Parallel Twin Shaft Mixers

Bowl Volume

500-4800

Liters

Max Mixing Capacity

825-8000

Lbs

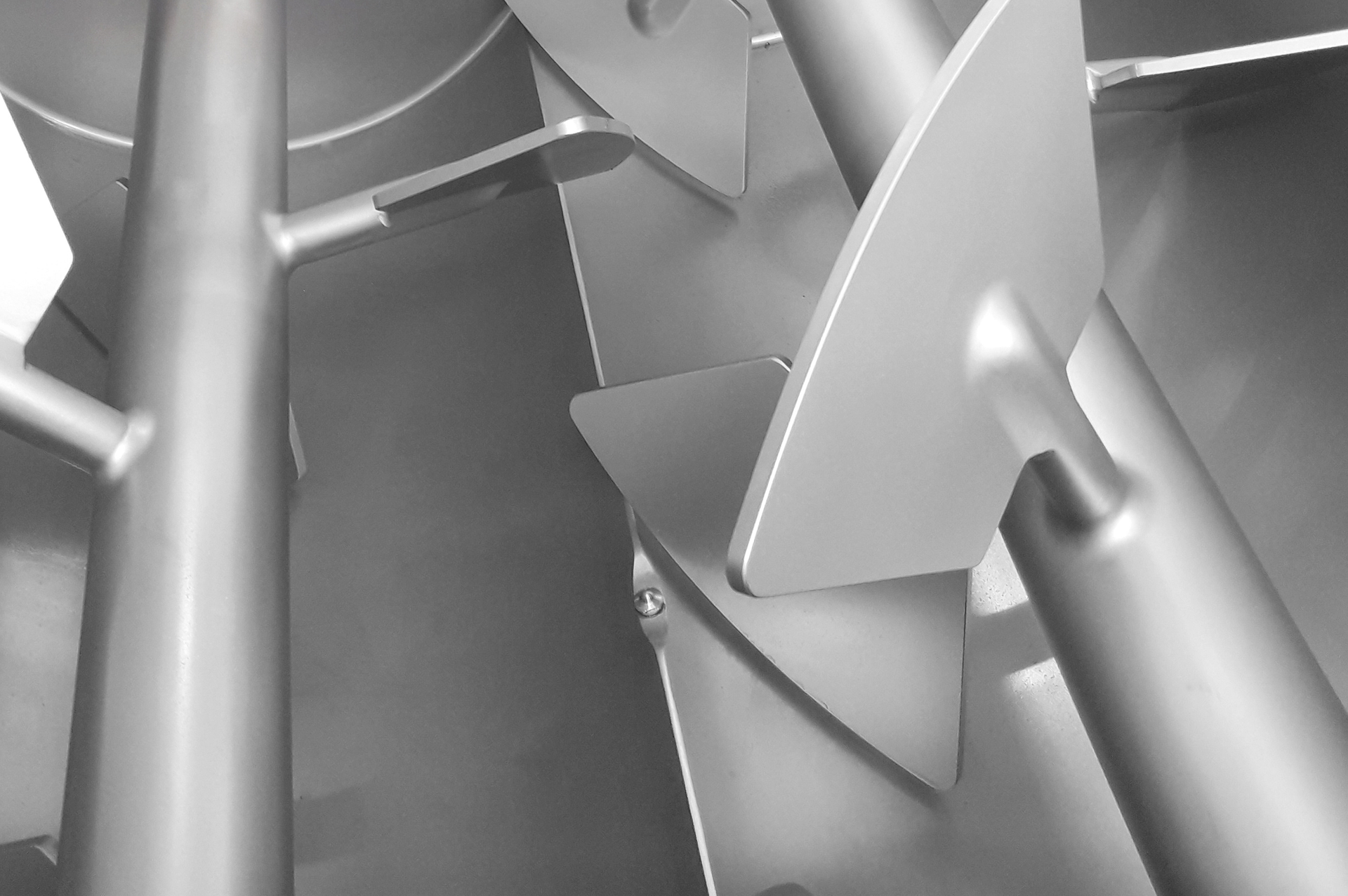

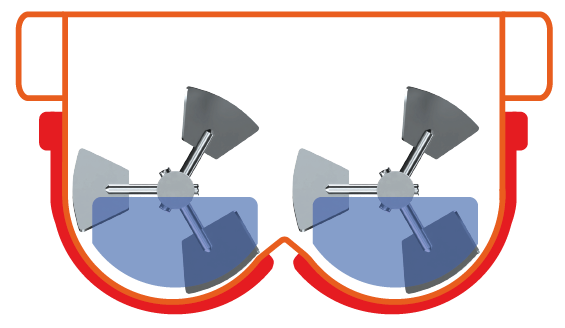

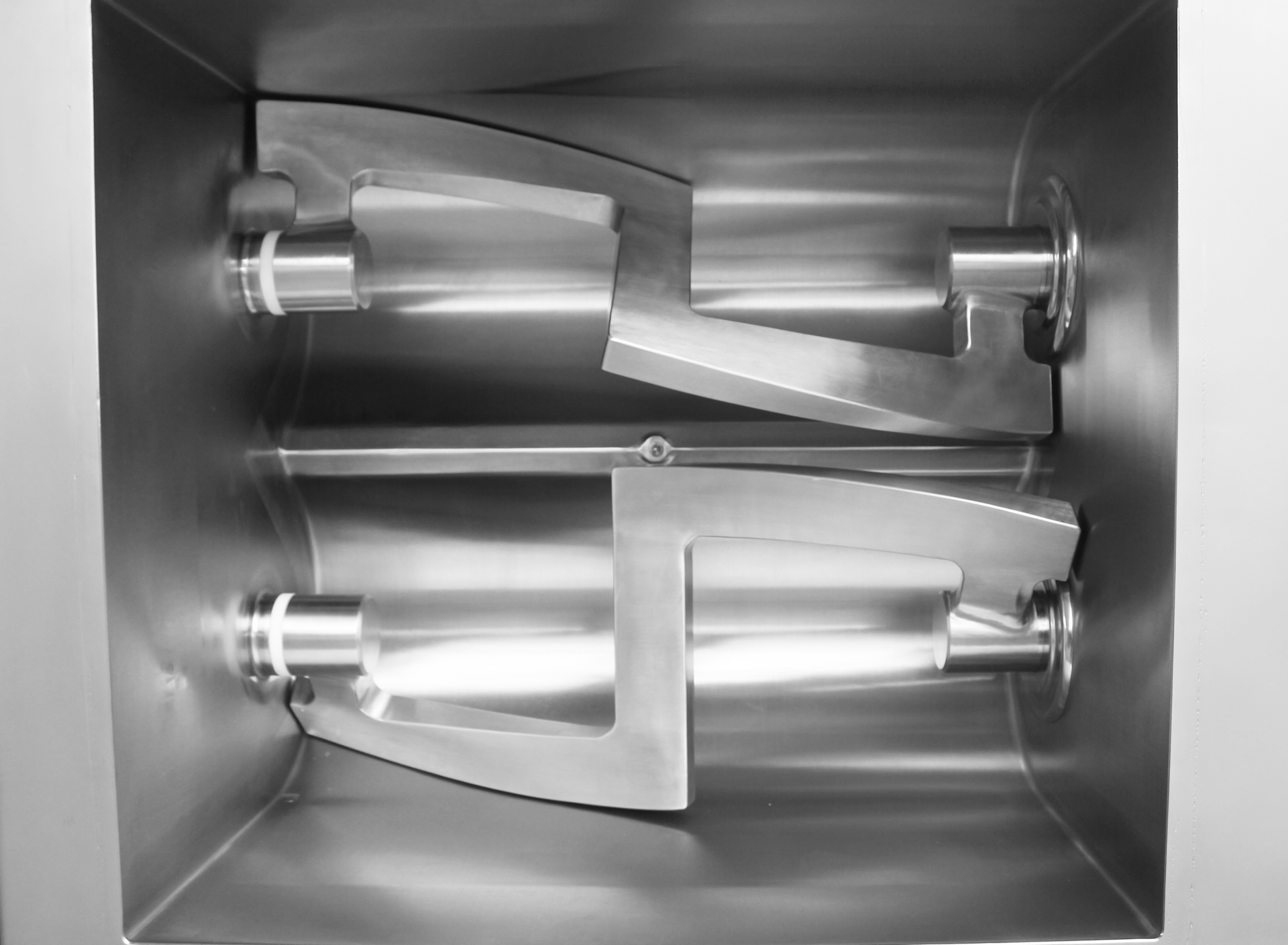

- Parallel Paddle or Ribbon Shafts: Features twin parallel paddle or ribbon shafts at the same height, allowing independent adjustment of speed and rotation direction for each shaft to ensure precise and flexible mixing for medium and high-density products.

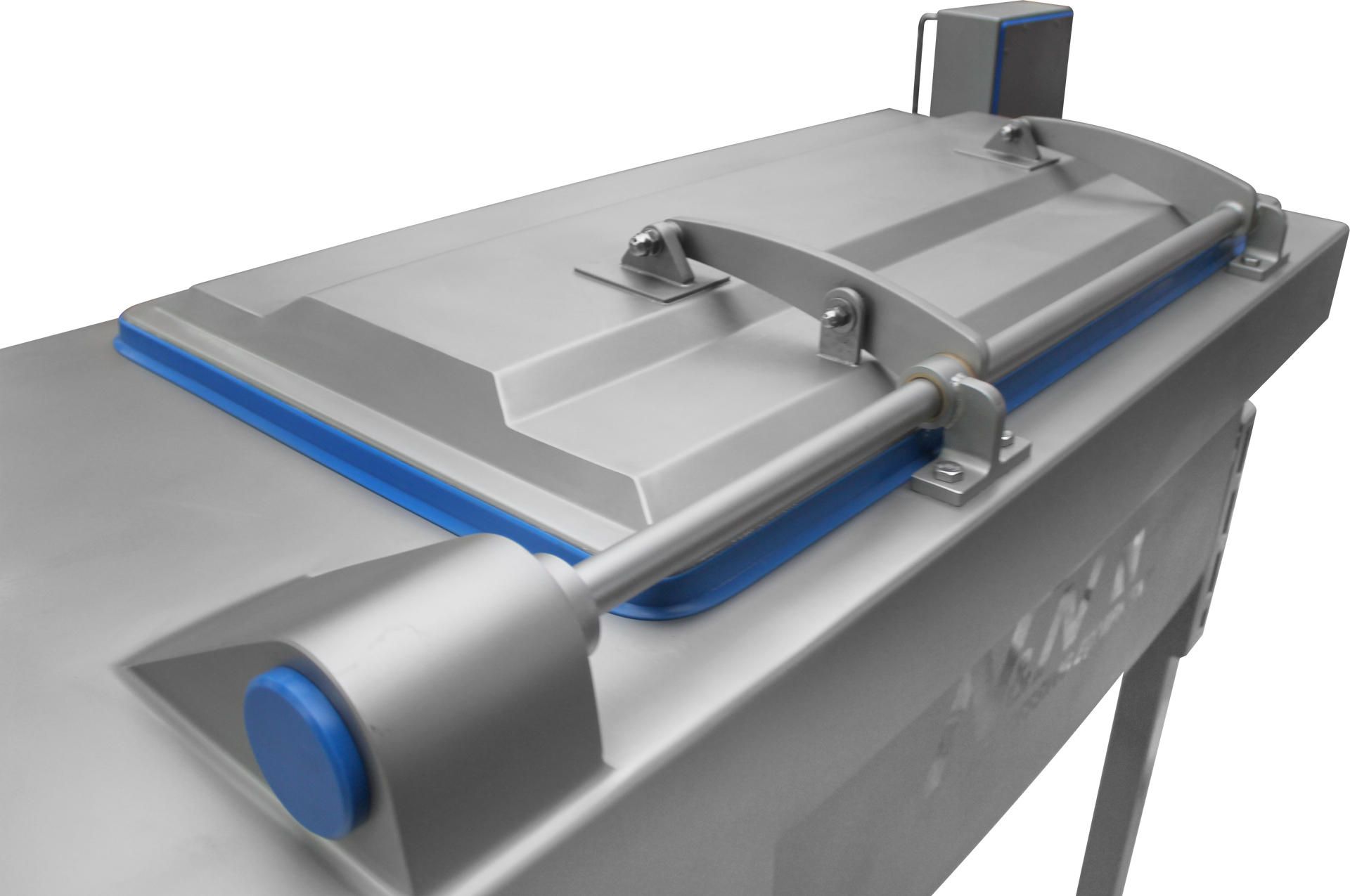

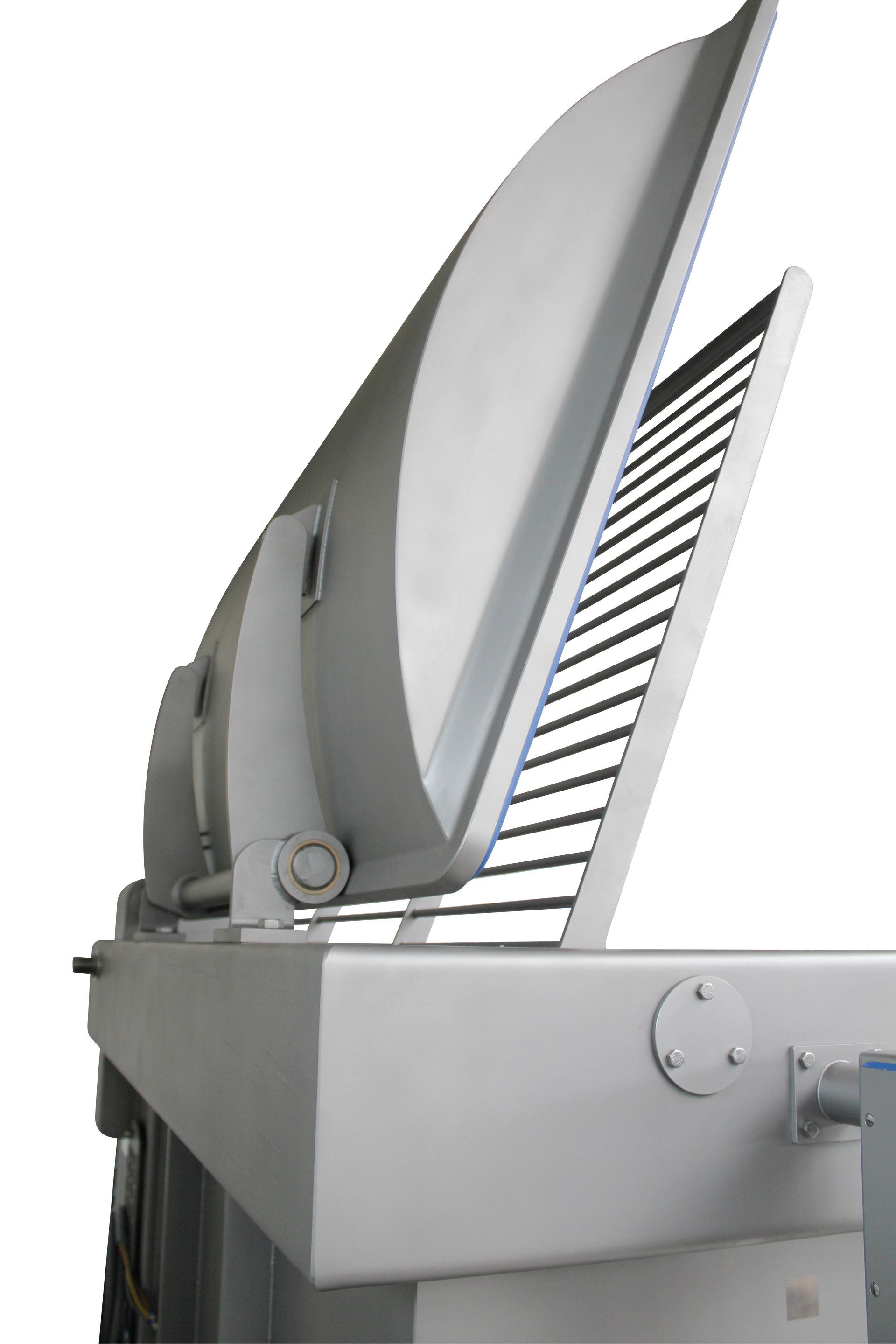

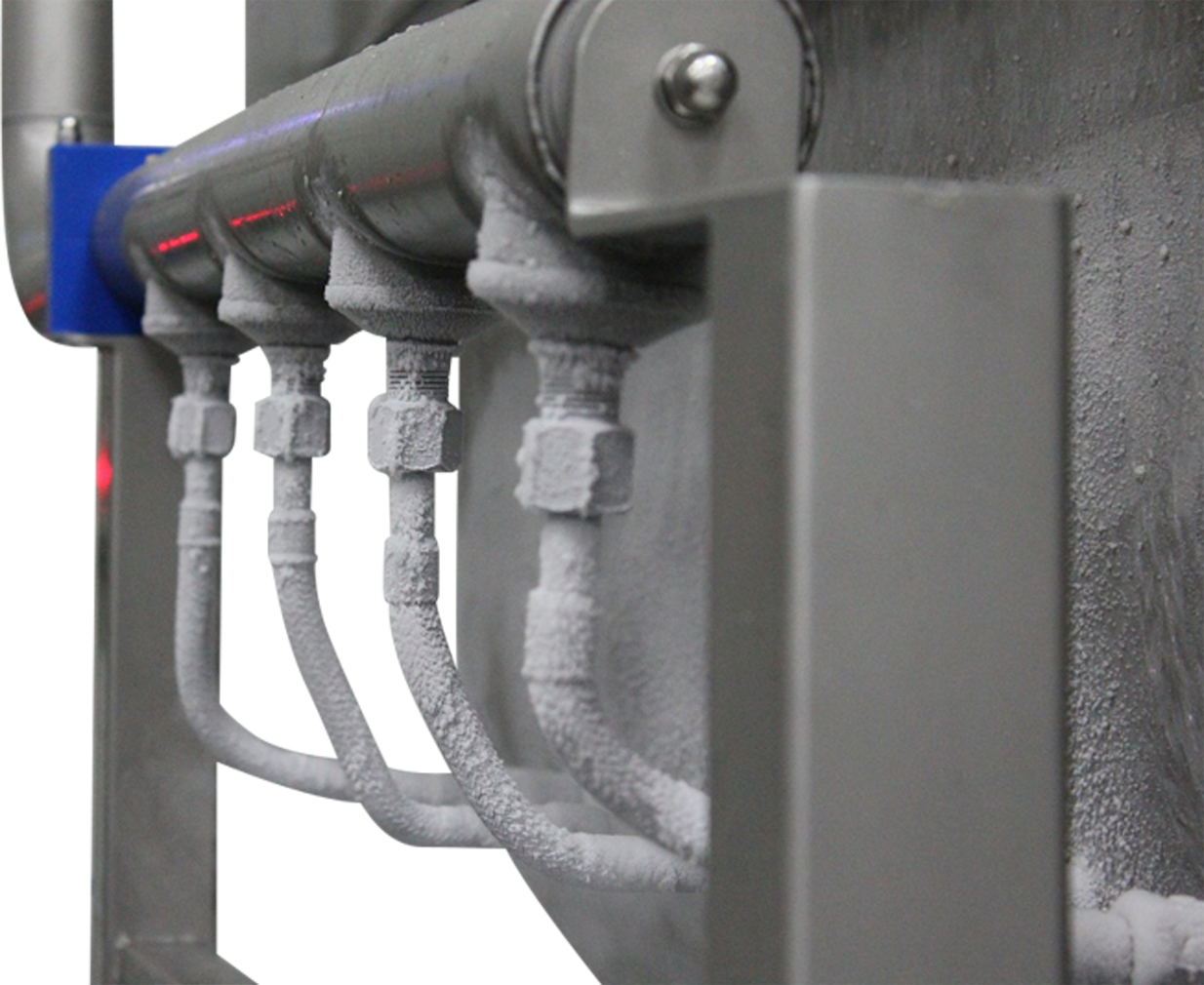

- Vacuum Option: Equipped with a reinforced bowl and airtight top cover, allowing up to 99% vacuum, which enhances protein extraction, liquid absorption, spice and additive distribution, density control, and eliminates air bubbles before emulsification, filling, or forming.

- Variable speed: Offers precise speed adjustments, allowing the shafts to rotate at any desired speed within the machine's range.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store up to 100 custom programs by adjusting variables such as shaft rotation speed, shaft rotation direction, and vacuum level.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient

Technical Information

Mix S

Mix SV

Applications

The MIX S and MIX SV series are versatile mixers designed to handle medium to high-density products. Depending on whether ribbon or paddle shafts are used, these mixers are designed for processing finely and very finely chopped meat fillings, cheese fillings, and even animal feed.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Introduction to the Series MIX S/SV Twin Shaft Paddle Mixers

What are the Series MIX S and MIX SV mixers designed for?

The Series MIX S and MIX SV mixers from BAK Food Equipment are advanced parallel twin shaft paddle or ribbon mixers engineered specifically for medium- and high-density food products. These mixers are built to deliver precise, consistent, and efficient mixing for a wide range of applications. The MIX S model is designed for standard mixing operations, while the MIX SV model incorporates a vacuum system capable of achieving up to 99% vacuum, which is particularly beneficial for processes that require enhanced protein extraction, improved liquid absorption, and the elimination of air bubbles prior to emulsification, filling, or forming.

What industries and products benefit most from twin shaft mixers?

Twin shaft mixers are highly versatile and serve a broad spectrum of industries. They are especially valuable in meat processing, cheese production, processed foods, and pet food manufacturing. The ability to handle finely and very finely chopped meat fillings, cheese fillings, and even animal feed makes these mixers a preferred choice for food processors seeking reliable and flexible solutions. The option to use either paddle or ribbon shafts further extends their suitability to different product textures and mixing requirements.

How do they improve efficiency and product quality?

The Series MIX S and MIX SV mixers are equipped with independently controlled parallel shafts, allowing operators to adjust both the speed and rotation direction of each shaft. This level of control ensures even distribution of ingredients and precise mixing, which directly translates to improved product consistency and quality. The vacuum functionality available in the MIX SV model enhances the mixing process by promoting better protein extraction, more uniform spice and additive distribution, and optimal density control. Additionally, the industrial-grade stainless steel construction, advanced programmable control panel, and easy-clean design contribute to operational efficiency, hygiene, and long-term durability, making these mixers a cornerstone of modern industrial food mixing operations.

Key Features and Options

What makes the MIX S/SV design unique?

The MIX S and MIX SV series from BAK Food Equipment stand out due to their parallel twin shaft configuration, which features either paddle or ribbon shafts positioned at the same height. This design allows for independent adjustment of each shaft’s speed and rotation direction, ensuring precise and flexible mixing for a wide range of medium to high-density products. The reinforced bowl and airtight top cover in the SV models enable up to 99% vacuum, which is critical for applications requiring enhanced protein extraction, improved liquid absorption, and the elimination of air bubbles prior to further processing. The fully welded, stainless steel construction not only ensures durability and longevity but also simplifies cleaning and maintenance, making these mixers ideal for demanding industrial environments.

How do the paddle/ribbon shaft options impact performance?

The choice between paddle and ribbon shafts directly influences the mixer’s performance and suitability for specific applications. Paddle shafts are particularly effective for gently blending products with varying particle sizes or delicate inclusions, ensuring even distribution without damaging the product. Ribbon shafts, on the other hand, are designed for more intensive mixing, making them ideal for finely or very finely chopped meat fillings, cheese blends, and similar products.

What features enhance efficiency, accuracy, and hygiene?

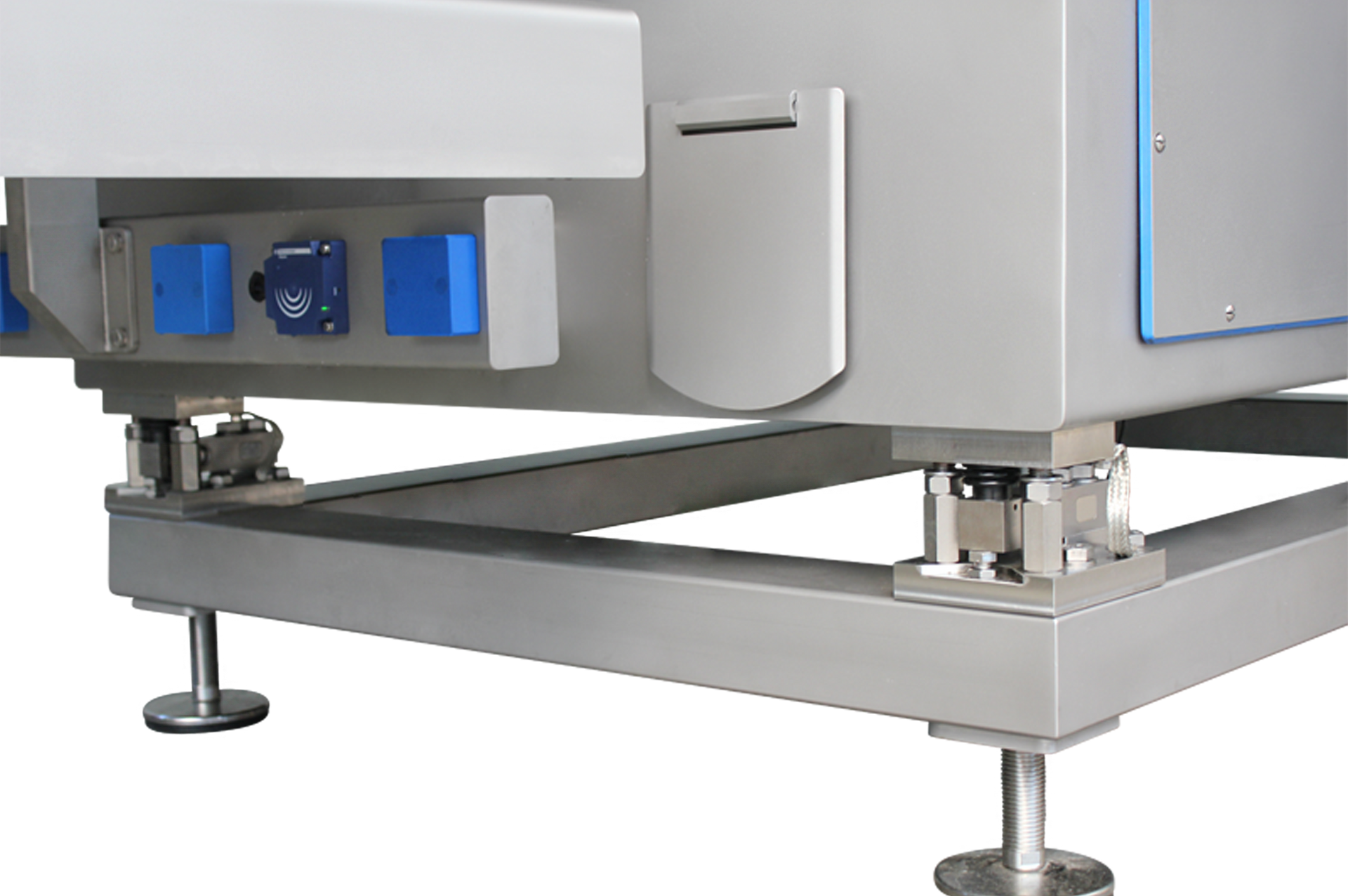

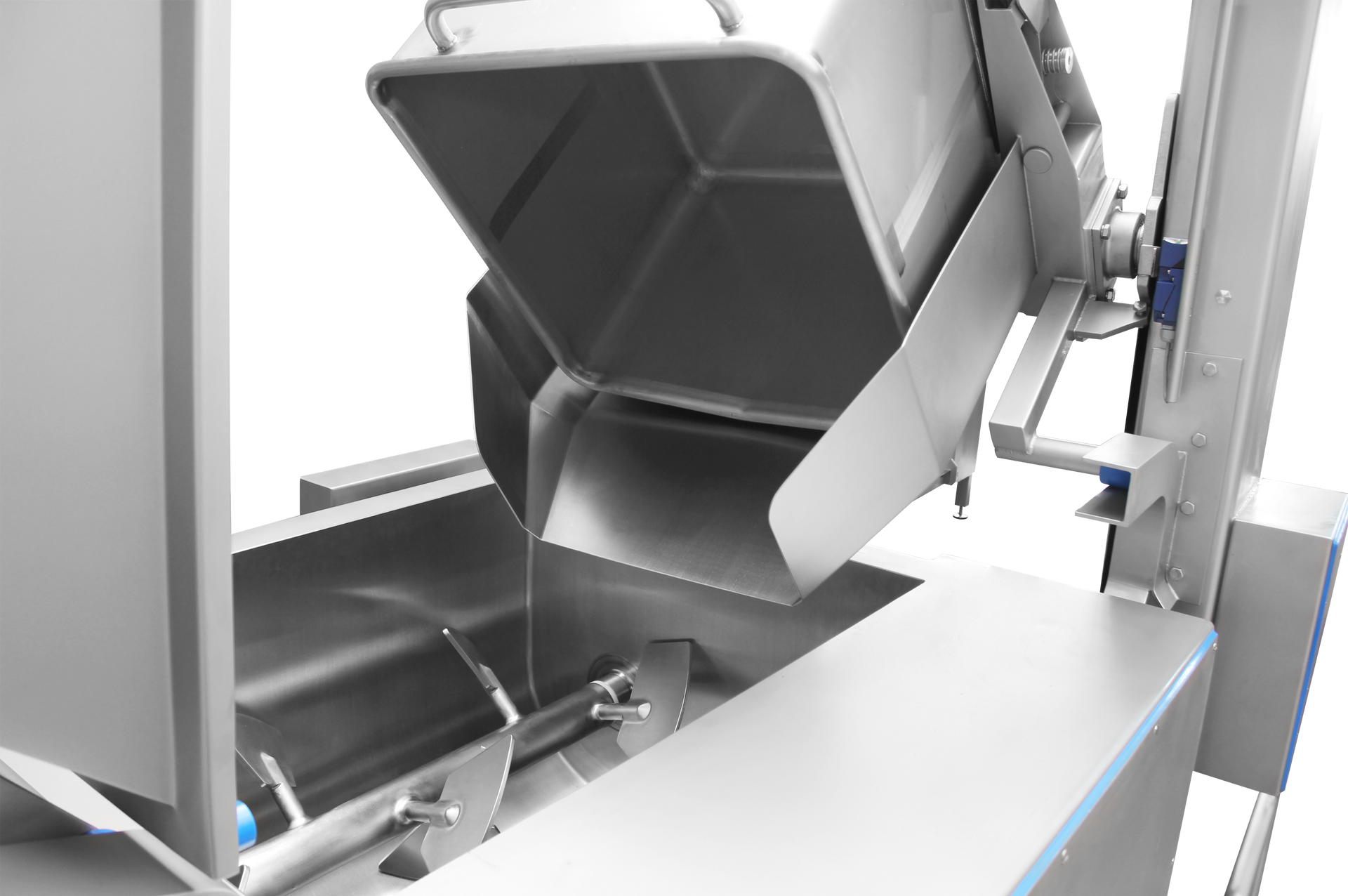

Efficiency, accuracy, and hygiene are at the core of the MIX S/SV series. Variable speed control allows operators to select gentle or aggressive mixing profiles as needed, optimizing both product quality and processing time. The advanced programmable control panel, featuring an intuitive touch screen, can store up to 100 custom recipes, each with adjustable parameters such as shaft speed, direction, and vacuum level. Integrated load cells provide real-time weighing accuracy, ensuring precise ingredient ratios and enabling automated batching for consistent output. The water dosage system automates the measurement and addition of liquids at programmed intervals, further enhancing batch consistency. Temperature monitoring and optional jacketed bowls (for cooling or heating) ensure thermal precision and product safety. The easy clean system, polished bowl and shaft surfaces, and fully welded construction all contribute to superior hygiene, reducing the risk of contamination and simplifying routine maintenance. These features collectively make the MIX S/SV series a leading choice for programmable food mixers, vacuum paddle mixers, stainless steel industrial mixers, and meat blending machines.

Sanitation, Safety, and Maintenance Features

How do these mixers simplify cleaning and maintenance?

BAK Food Equipment’s parallel twin shaft mixers are engineered with a strong focus on hygienic design and maintenance-friendly equipment. The Easy Clean System is a standout feature, utilizing monolithic silicone seals and combined with tool-free interior access makes cleaning more simple. This allows operators to quickly and thoroughly clean all internal surfaces, minimizing downtime and ensuring that sanitation routines are both effective and efficient. The polished bowl and shafts further enhance cleanability by providing smooth surfaces that prevent product from sticking or residue from building up, making routine cleaning faster and more reliable.

What features ensure food safety and compliance?

Food safety compliance is integral to the design of these mixers. The fully sealed cover is essential for preventing product loss and dust escape, which is particularly important in powder or vacuum applications. This airtight seal not only maintains product integrity but also supports a clean-in-place system, reducing the risk of cross-contamination. For operations that require the addition of spices or other additives during mixing, an optional openwork cover is available. This feature enables safe ingredient additions without halting production, maintaining both safety and efficiency. Automatic lid operation, achieved through pneumatic or hydraulic systems, ensures that the lid can be opened and closed safely and conveniently, reducing manual handling and potential safety risks.

Applications Across Food Processing Industries

What industries commonly use the MIX S and MIX SV models?

The MIX S and MIX SV parallel twin shaft mixers from BAK Food Equipment are engineered for versatility, making them a staple across a wide range of food processing industries. These mixers are widely adopted in meat and poultry processing, where their robust design and precise mixing capabilities are essential for producing consistent, high-quality products. The dairy industry also benefits from these mixers, particularly in cheese processing, where uniform blending of curds and additives is critical. Seafood processors utilize the MIX S and MIX SV models for preparing finely chopped or emulsified seafood fillings, while manufacturers of ready-to-eat meals and deli products rely on these mixers for their ability to handle dense mixtures and ensure even ingredient distribution. Additionally, the pet food industry leverages these mixers for producing both wet and dry animal feed, where consistent texture and thorough mixing are paramount. The adaptability of these mixers, including options for ribbon or paddle shafts and vacuum operation, allows them to meet the specific requirements of each sector, from high-volume industrial food production to specialized applications in cheese and pet food processing.

What types of products benefit most from this mixing system?

The MIX S and MIX SV mixing systems are particularly well-suited for products that demand uniform texture, even ingredient distribution, and consistent yield. These mixers excel in processing finely chopped or emulsified ingredients, making them ideal for meat fillings, sausage mixes, and pâtés. Their ability to handle pastes and dense mixtures also makes them a good choice for cheese fillings, spreads, and processed cheese products. In the production of sauces, dressings, and deli fillings, the precise control over mixing speed and direction ensures that all components are thoroughly blended, resulting in a homogenous final product. The vacuum option available on the MIX SV models further enhances product quality by improving protein extraction, liquid absorption, and spice distribution, while eliminating air bubbles—an essential feature for products destined for emulsification, filling, or forming. Pet food manufacturers benefit from the mixers’ capacity to process both finely ground and coarser ingredients, ensuring a consistent product that meets nutritional and textural standards. Overall, the MIX S and MIX SV mixers are indispensable for any application where product consistency, texture, and quality are non-negotiable.

Partner with BAK for Precision Mixing Solutions

Why choose BAK for twin shaft mixing equipment?

BAK Food Equipment stands out as a trusted partner for processors seeking advanced twin shaft mixing solutions. Our mixers are engineered for exceptional durability, flexibility, and efficiency, ensuring that your production line operates at peak performance. Constructed entirely from industrial-grade stainless steel, BAK’s parallel twin shaft mixers are built to withstand the rigors of continuous operation in demanding food processing environments. The robust design not only extends equipment life but also minimizes downtime, supporting uninterrupted production.

Each BAK mixer can be tailored to your specific product characteristics and production goals. With options for parallel paddle or ribbon shafts, processors can independently adjust the speed and rotation direction of each shaft, achieving precise and flexible mixing for a wide range of medium to high-density products. The availability of vacuum mixing, advanced programmable control panels, and a variety of customizable features—such as temperature monitoring, jacketed bowls, and automated loading systems—ensures that every system is optimized for your unique requirements.

How does BAK support long-term operational success?

BAK Food Equipment is committed to supporting your long-term operational success through proven reliability and expert technical support. Our mixers are designed for easy cleaning and maintenance, reducing the time and labor required for routine upkeep. In addition, our technical team is available to provide guidance, troubleshooting, and ongoing support, helping you maximize equipment uptime and throughput.

Whether you are integrating a new mixer into an existing production line or designing a complete industrial mixing solution from the ground up, BAK’s expertise in food processing machinery and production line integration ensures a seamless transition and sustained operational excellence.

Contact BAK Food Equipment today to discuss your specific mixing requirements and discover how our precision-engineered solutions can elevate your processing capabilities.

Twin Shaft Mixer FAQs

What is the difference between the MIX S and MIX SV models?

The MIX S is BAK Food Equipment’s standard twin shaft mixer, engineered for robust and consistent mixing of medium to high-density products. The MIX SV, on the other hand, incorporates a reinforced bowl and an airtight top cover, enabling a vacuum system capable of achieving up to 99% vacuum.

What types of shafts are available?

The Series MIX S/SV can be equipped with either paddle or ribbon shafts. Paddle shafts are well-suited for mixing dense or sticky products, ensuring thorough blending and even distribution of ingredients. Ribbon shafts, meanwhile, are designed for more delicate or finely chopped mixtures, providing gentle yet effective mixing. This flexibility allows processors to select the optimal shaft type based on their specific product requirements and desired texture outcomes.

Can the system handle both hot and cold mixing applications?

Yes, both the MIX S and MIX SV models can be fitted with an optional heating and cooling jacket. This feature allows for precise temperature control throughout the mixing process, making these mixers suitable for a wide range of applications, from chilled doughs to hot cheese fillings. The ability to maintain or adjust product temperature during mixing is crucial for ensuring product consistency and meeting food safety standards.

How do the load cells improve efficiency?

Load cells are integrated into the mixer design to monitor weight changes in real time. This automation enables precise ingredient addition, preventing over- or under-loading and ensuring consistent batch quality. By automating the weighing process, load cells reduce manual labor, minimize errors, and streamline production, ultimately improving overall efficiency and product consistency.

Are these mixers suitable for pet food or non-meat applications?

Absolutely. The Series MIX S/SV is engineered for versatility and can handle a variety of products beyond traditional meat processing. These mixers are ideal for pet food, cheese fillings, doughs, and other dense or sticky products. Their robust construction and customizable features make them a reliable choice for processors in multiple food sectors.

How easy is cleaning and maintenance?

Cleaning and maintenance are straightforward thanks to the Easy Clean system and the smooth, polished interiors of the bowl and shafts. Operators can perform complete cleanouts quickly and efficiently, often without the need for tools. This design not only reduces downtime but also supports stringent hygiene standards required in food processing environments.

Can these mixers be integrated into automated production lines?

Yes, the MIX S and MIX SV mixers are designed with automation in mind. They can be customized with loaders, sensors, SCADA integration, and programmable controls, allowing seamless integration into fully automated production lines. This adaptability supports processors aiming to scale up production, improve traceability, and enhance operational efficiency.

For more information about our warranty and service options, please visit our warranty page.