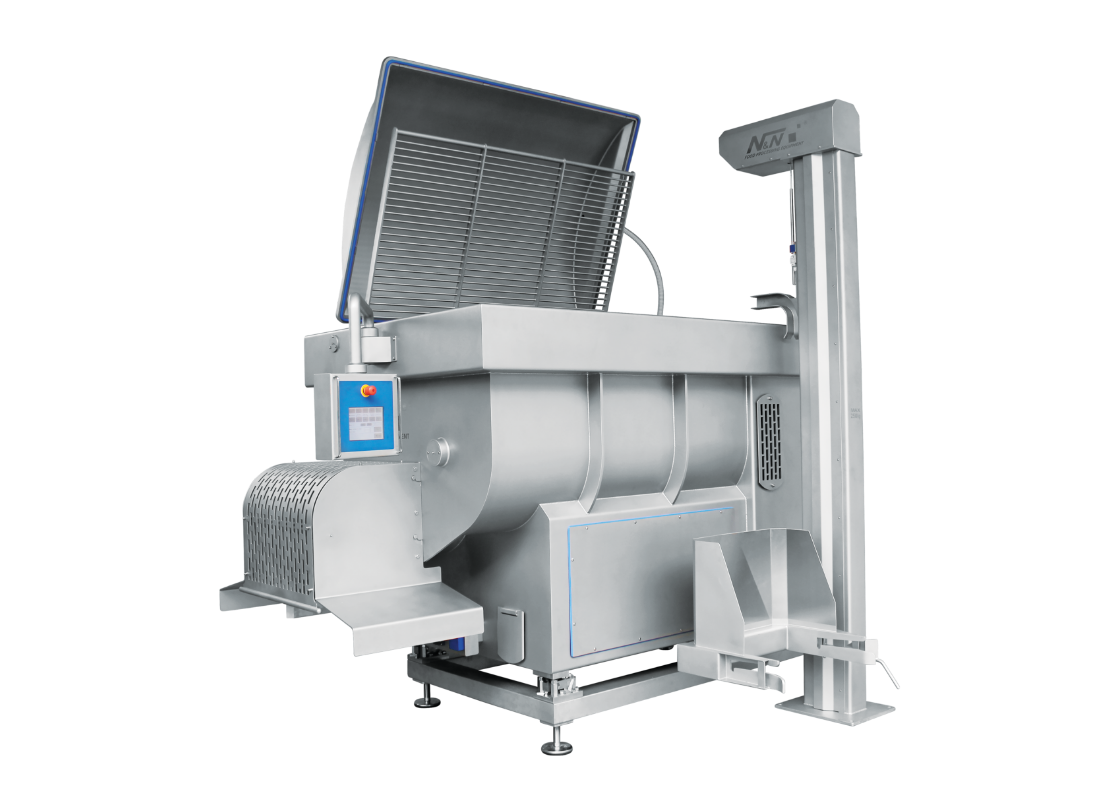

Series MH

SAS Brine Injectors - Industrial Meat Injectors

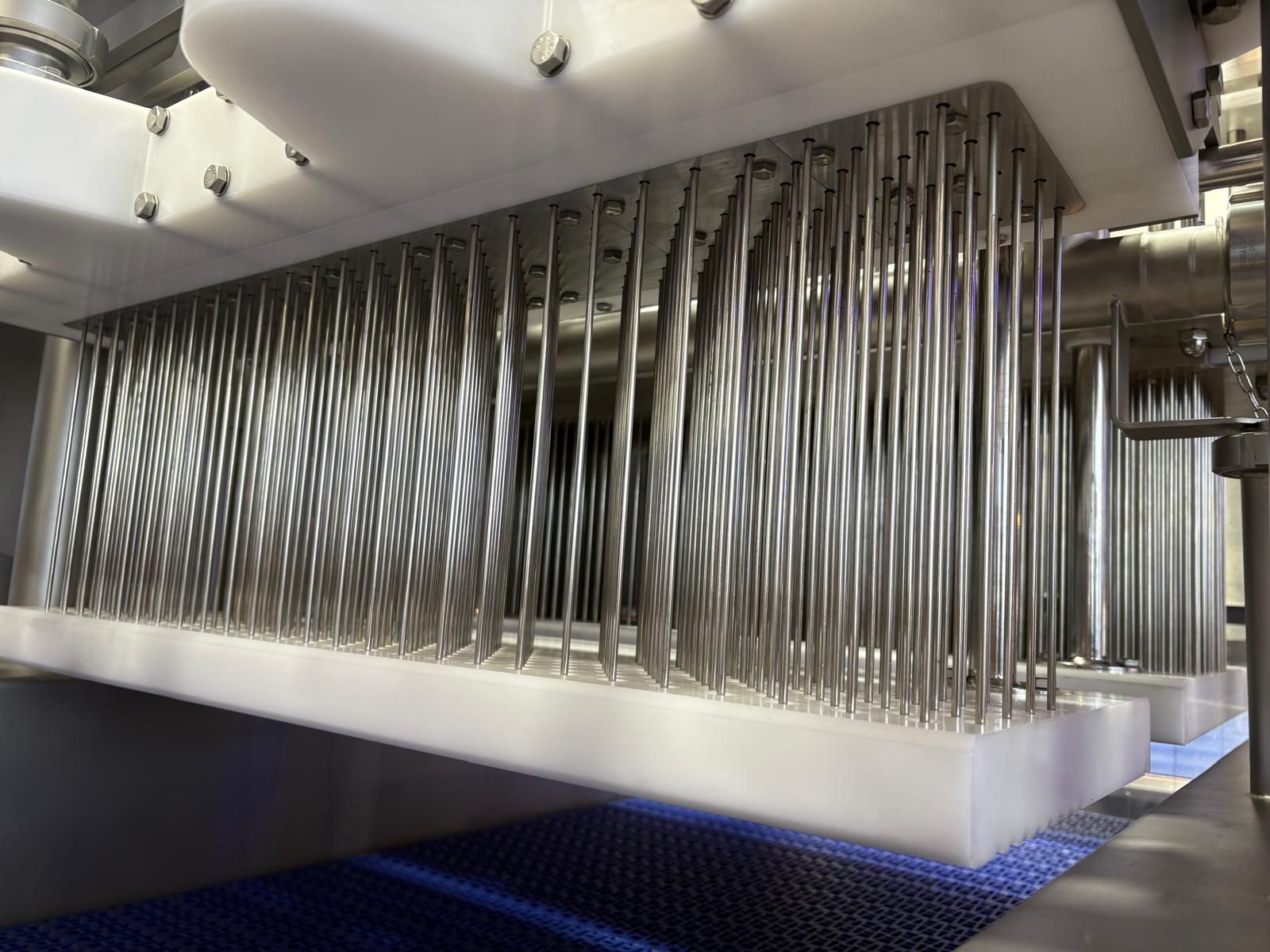

Needles

117 to 1,480

Needles

Conveyor Width

18 - 41

In.

- High-Performance Servo Design: Powered by servo motors, enabling the machine to handle high workloads with precision and consistency.

- Variable Parameter Control: Easily adjust all injection parameters such as injection stroke length, duration of injection, position of injection (on descent or ascent of the head), injection head speed, speed of the belt, and brine pump pressure. The machine is capable of operating at any setting within its full range, ensuring optimal performance for your specific needs.

- Bone-In or Boneless Capability: The machine is designed to efficiently handle both bone-in and boneless products, offering versatility for various processing needs.

- Ergonomic Injector Head Handling: A new crank-and-rail arm system allows for safer, easier handling of the injector head—minimizing strain and improving operator efficiency.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

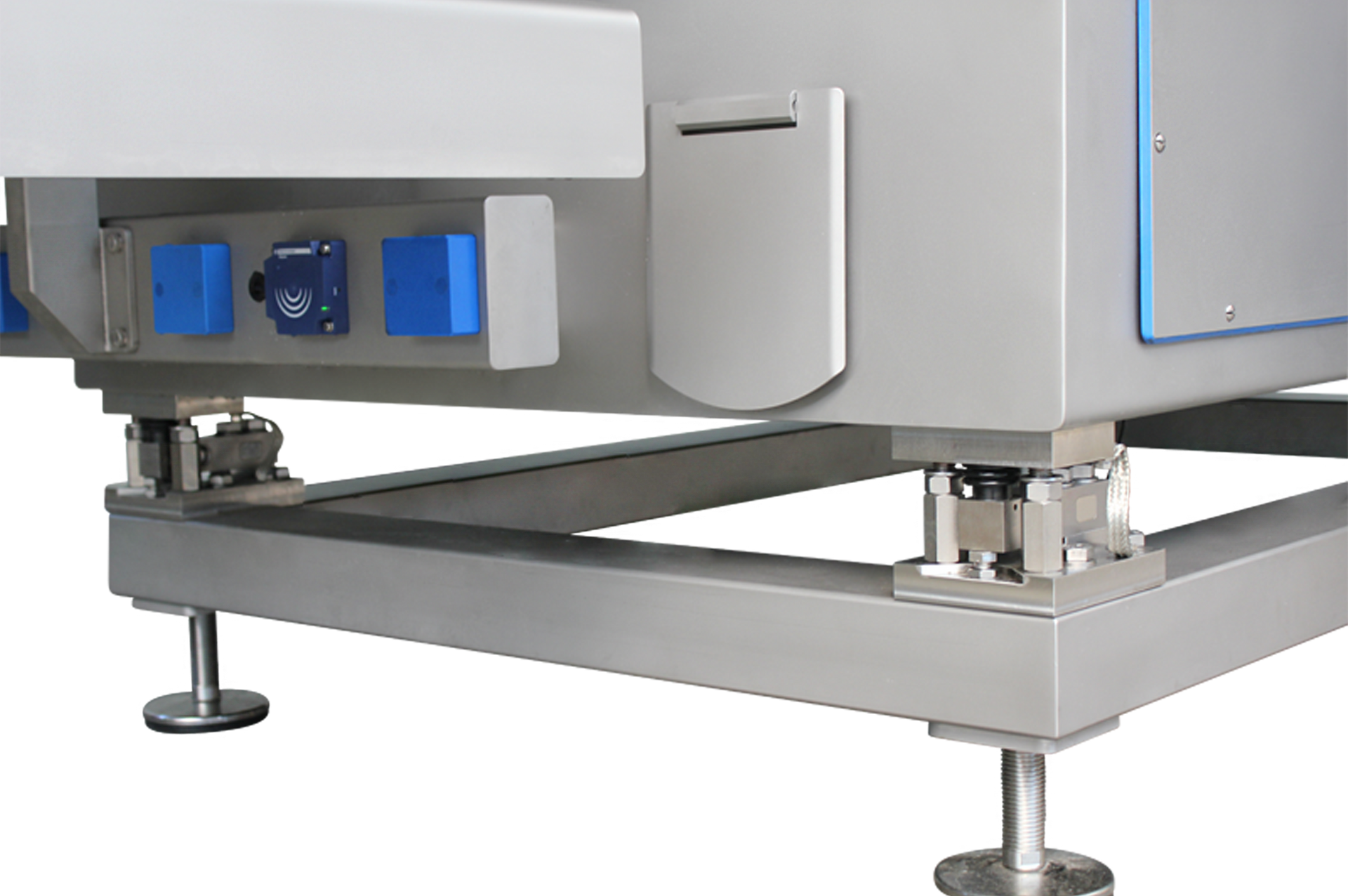

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store 99 custom programs by adjusting variables such as injection stroke length, duration of injection, position of injection (on descent or ascent of the head), injection head speed, speed of the belt, and brine pump pressure.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient. The needle heads and individual needles can easily be removed for cleaning and maintenance

Technical Information

MH 660 and MH 1480 needle configurations were specially design for fish products

Regular

Fish Oriented

Applications

NOMA SAS Brine Injectors are designed for high-production brine injection across a variety of products, including bone-in or boneless meats, whole poultry and poultry parts, as well as fish and fish fillets. These injectors ensure consistent flavor and moisture distribution, delivering reliable results for large-scale operations.

Clarion Locker

"Before the NOMA injector, we spent two grueling days on manual brine injection. Now, it’s down to under an hour—and the results are so impactful, my wife jokes that she’d rather give me up than give up this machine.” – Owner

You Might Also Like

About Industrial Meat Injectors

What is an industrial meat injector?

An industrial meat injector is a specialized piece of meat processing equipment designed to inject brine, marinades, or other flavoring solutions directly into meat products. These machines use multiple needles—ranging from 117 to 1,480 in the case of BAK Food Equipment’s SAS Brine Injectors—to deliver precise amounts of liquid into bone-in or boneless meats, whole poultry, poultry parts, and fish or fish fillets. The injection process is highly controlled, with advanced features such as servo motor-driven operation, programmable control panels, and adjustable parameters for injection stroke, speed, and pressure. This ensures that each product receives a consistent and uniform distribution of brine or marinade.

How does it improve flavor, consistency, and efficiency in meat processing?

Industrial meat injectors play a critical role in enhancing the flavor, texture, and moisture retention of meat products. By injecting brine or marinade deep into the muscle tissue, these machines ensure that flavors are evenly distributed throughout the product, rather than just on the surface. This results in a more flavorful and juicy end product, with improved texture and mouthfeel. The automation of the injection process also eliminates the variability associated with manual methods, leading to greater consistency across batches. Additionally, the ability to adjust injection parameters allows processors to tailor the process to different types of meat and desired outcomes, further enhancing product quality and uniformity.

Why are injectors essential for large-scale operations?

For large-scale meat processing operations, industrial injectors are indispensable. They significantly increase production efficiency by automating the brine injection process, allowing for high throughput and consistent results. Machines like the SAS Brine Injectors from BAK Food Equipment are built for durability and ease of maintenance, with features such as stainless steel construction, ergonomic injector head handling, and easy-to-clean needle assemblies. These attributes reduce downtime and labor costs, while ensuring food safety in meat processing. The versatility to handle a wide range of products—from bone-in hams to delicate fish fillets—makes these injectors a vital component in any modern, high-volume meat processing facility.

Key Features of the Industrial Meat Injectors

What features make the SAS brine injectors stand out?

The SAS brine injectors from BAK Food Equipment are engineered to deliver high-performance, precision, and versatility for industrial meat processing. One of the most notable features is their high-performance servo design, which enables the injectors to handle demanding workloads with exceptional accuracy and consistency. The machines are constructed entirely from durable stainless steel, ensuring longevity and reliable operation even in the most rigorous production environments. Additionally, the SAS brine injectors are designed to accommodate both bone-in and boneless products, making them suitable for a wide range of applications, including whole poultry, poultry parts, fish, and fish fillets. The ergonomic injector head system, featuring a crank-and-rail arm, allows for safer and easier handling, minimizing operator strain and improving efficiency. Easy cleaning and maintenance are also prioritized, with removable heads and needles that streamline routine sanitation and upkeep, supporting food safety standards and production consistency.

How do servo-driven motors improve accuracy and consistency?

Servo-driven motors are at the core of the SAS brine injectors’ performance. These motors provide precise control over all aspects of the injection process, including stroke length, injection duration, and needle position. This high level of control ensures that each product receives a consistent amount of brine or marinade, regardless of variations in product size or type. The result is uniform flavor and moisture distribution, which is critical for maintaining product quality and meeting the expectations of large-scale, automated meat processing operations. The servo-driven design also allows the injectors to operate efficiently at any setting within their full range, adapting seamlessly to different production requirements.

How do programmable settings improve flexibility in production?

The SAS brine injectors are equipped with an advanced, intuitive touch-screen control panel that allows operators to create and store up to 99 custom programs. This programmable interface enables precise adjustment of key parameters such as injection stroke length, duration, head speed, belt speed, and pump pressure. By tailoring these settings to specific products or recipes, processors can quickly switch between different production runs without extensive downtime or manual recalibration. This flexibility is essential for modern industrial food machinery, where rapid adaptation to changing market demands and product specifications is a competitive advantage. The ability to program and recall custom settings not only enhances operational efficiency but also supports consistent product quality across diverse production lines.

Models and Configurations

What injector sizes and capacities are available?

BAK Food Equipment offers a comprehensive range of SAS Brine Injectors, designed to meet the needs of both small-scale processors and high-capacity industrial operations. The models span from the compact MH 117, equipped with 117 needles and a conveyor width of 17.7 inches, to the robust MH 1480, which features 1,480 needles and a conveyor width of 41.3 inches. Injection volumes are highly flexible, ranging from 5% up to 120%, allowing processors to tailor the brine content to specific product requirements. Machine sizes and weights vary accordingly, with lengths from approximately 96 inches to over 193 inches and weights from 2,205 lbs to over 5,400 lbs, ensuring there is a suitable model for every production scale. This versatility makes these high-capacity meat injectors ideal for a wide variety of applications, from bone-in and boneless meats to whole poultry and poultry parts.

Which configurations are best for fish vs. meat?

While all SAS Brine Injectors are engineered for consistent and efficient brine distribution, certain models are specifically optimized for fish processing. The MH 660 and MH 1480 are designed with fish fillets and fish products in mind, offering needle sizes and configurations, and conveyor widths that accommodate the delicate nature and size of fish. The MH 660, for example, features 660 smaller needles and a 23.6-inch conveyor width, making it ideal for high-throughput fish injection applications. For meat and poultry processing, models such as the MH 212, MH 350, MH 516, and MH 774 provide a range of needle counts (from 212 up to 774) and conveyor widths (up to 41.3 inches), supporting both bone-in and boneless products. This adaptability ensures processors can select the optimal configuration for their specific product type, whether they require fish injection machines or meat and poultry processing equipment.

Across all models, advanced features such as servo-driven operation, programmable control panels, and ergonomic injector head handling contribute to precise, repeatable results and ease of use. The ability to adjust parameters like injection stroke, head speed, and brine pump pressure further enhances the flexibility and performance of these automated production lines.

Options & Customization

What add-ons are available for SAS brine injectors?

SAS brine injectors from BAK Food Equipment are designed with a range of optional add-ons to enhance their versatility and performance in meat processing environments. Available options include a brine chiller, SCADA monitoring system, load cells, a tenderizing head, and a rotary filter. Each of these add-ons is engineered to address specific operational needs, allowing processors to tailor the injector to their unique production requirements. This flexibility ensures that the SAS brine injectors can be adapted for various product types, including bone-in or boneless meats, poultry, and fish, as well as different plant layouts and production volumes.

How do these options improve performance?

The optional add-ons for SAS brine injectors significantly improve efficiency, monitoring, and end-product quality. The brine chiller maintains optimal brine temperature, which is crucial for consistent injection and food safety. The SCADA monitoring system provides advanced food production monitoring capabilities, enabling real-time tracking and control of injection parameters for better process oversight and traceability. Load cells offer precise measurement of product weight before and after injection to make sure that injection targets are hit. This ensures accurate brine management and consistent product quality. The tenderizing head enhances meat tenderization, improving texture and allowing for better brine absorption. Finally, the rotary filter ensures that the brine remains free of particulates, reducing the risk of needle blockages and maintaining smooth operation. Together, these options provide processors with the tools to maximize productivity, maintain high standards of quality, and adapt to evolving production demands.

Benefits of Brine Injectors

What is a brine injector machine?

A brine injector machine is designed to inject a brine solution directly into meat, poultry, and fish products. This equipment plays a crucial role in enhancing the moisture content, flavor, and overall yield of these products. By delivering a consistent and controlled amount of brine, the machine ensures that the final product is juicy, flavorful, and has improved texture.

How do brine injector machines work?

Brine injector machines operate by using multiple needles that penetrate the product to deliver the brine solution evenly throughout. The Series MHM Mechanical Brine Injectors from BAK Food Equipment exemplify this technology with needle configurations ranging from 21 to 204 needles, adaptable to various product sizes and types. These machines feature an integrated brine tank and filtration system that recirculates excess brine for efficient operation. Operators can adjust injection parameters such as injection head speed, brine pump pressure, and conveyor speed through an advanced programmable control panel, allowing precise control over the injection process. The needles can be customized with single, double, triple, or quadruple configurations to meet specific processing needs. The entire system is constructed from stainless steel, ensuring durability and ease of cleaning and maintenance.

Why are brine injector machines important for meat, poultry, and fish processing?

Brine injector machines are vital in the meat processing industry because they significantly improve product quality and processing efficiency. By injecting brine, these machines enhance moisture retention, which leads to juicier and more tender meat, poultry, and fish. This process also boosts flavor uniformly throughout the product, ensuring a consistent taste experience. The versatility of the Series MHM injectors allows them to handle bone-in and boneless products effectively, making them indispensable equipment in modern meat processing operations. Their robust industrial-grade construction and advanced control features make them reliable and adaptable to various production requirements.

FAQ Section – Industrial Meat Injectors

What is the purpose of an industrial meat injector?

An industrial meat injector is designed to inject brine or marinade directly into meats, poultry, or fish. This process ensures that flavor, tenderness, and moisture are distributed consistently throughout the product, which is especially important in high-volume production environments. By using an injector, processors can achieve uniform product quality, reduce manual labor, and improve overall efficiency. The result is a more flavorful, tender, and juicy end product that meets the demands of both consumers and commercial buyers.

Can the SAS brine injectors handle both bone-in and boneless products?

Yes, the SAS brine injectors are engineered for versatility and can efficiently process both bone-in and boneless meats. This capability allows processors to use the same equipment across a wide range of product lines, from whole poultry and poultry parts to various cuts of beef, pork, and even fish. The robust design and adjustable parameters ensure precise injection regardless of the product type, making the SAS brine injector a flexible solution for diverse processing needs.

What makes the SAS brine injector different from standard meat injectors?

The SAS brine injector stands out due to its high-performance servo-driven motors, which provide precise control over all injection parameters. Operators can easily adjust stroke length, injection duration, head speed, belt speed, and brine pump pressure to match specific product requirements. The ergonomic crank-and-rail arm system enhances operator safety and efficiency when handling the injector head. Additionally, the advanced programmable control panel allows users to store up to 99 custom recipes, streamlining production and ensuring repeatable results. These features collectively deliver superior consistency, flexibility, and ease of use compared to standard injectors.

Are SAS brine injectors suitable for fish processing?

Absolutely. The MH 660 and MH 1480 models are specifically designed for fish and seafood applications. These configurations ensure gentle yet thorough injection, maintaining the integrity of delicate fish fillets while delivering consistent flavor and moisture. This makes the SAS brine injector an excellent choice for processors handling a variety of seafood products, in addition to traditional meat and poultry lines.

How easy is it to clean and maintain the SAS brine injector?

The SAS brine injector is constructed entirely from stainless steel, ensuring durability and resistance to corrosion in demanding processing environments. Cleaning and maintenance are straightforward, thanks to the removable needle heads and sockets. This design allows for quick disassembly, thorough cleaning, and easy reassembly, minimizing downtime and supporting food safety standards. Routine maintenance tasks are simplified, helping processors maintain peak performance and extend equipment lifespan.

What options can be added to the SAS brine injectors?

To further enhance performance and monitoring, the SAS brine injectors can be equipped with several optional upgrades. These include a brine chiller for temperature control, SCADA monitoring for real-time data tracking, load cells for precise brine management, a tenderizing head for improved texture, and a rotary filter for brine purity. These options allow processors to tailor the injector to their specific production requirements and quality standards.

What industries typically use industrial meat injectors?

Industrial meat injectors are widely used in large-scale meat processing plants, poultry facilities, and fish processing operations. These industries rely on injectors to improve product consistency, increase throughput, and maintain high standards of quality and food safety. For more information on specific applications, visit our applications page.