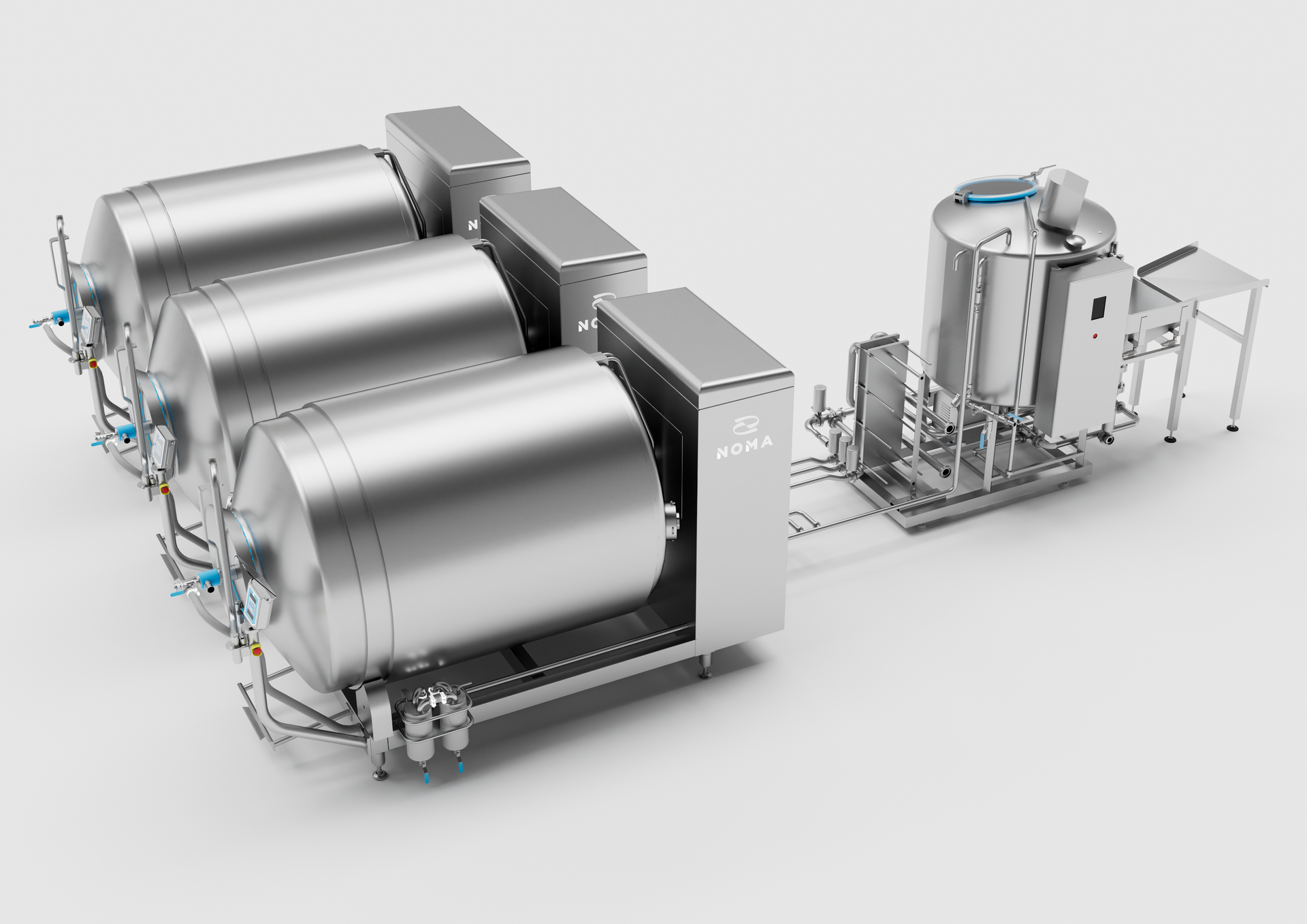

Series MS, BM

Single Unit Brine Mixers

Capacity:

250 to 2,000

Liter

- Mixing System: Features mechanical agitators for efficient mixing ensuring a homogenous brine solution in a short time. It is also capable of integrating with a brine injector for a seamless operation.

- Centrifugal Brine Circulation System: Equipped with an efficient centrifugal pump that ensures excellent blending of dry ingredients in water. This also allows for easy transportation of the prepared brine.

- CIP-Integrated Automatic Washing System (BM Series): Guarantees the highest standards of machine hygiene and microbiological safety of prepared brine solutions. Features a uniquely designed swivel head for easy, quick, and thorough cleaning of the inside of the working tank.

- Recipe Management Option (BM Series):Ensures operators consistently follow the correct brine recipe by providing clear, step-by-step instructions on what to add next, streamlining the brine preparation process.

Why Choose BAK

Durable, Industrial-Grade Construction:

Built entirely from stainless steel for exceptional durability and long-lasting performance in demanding environments.

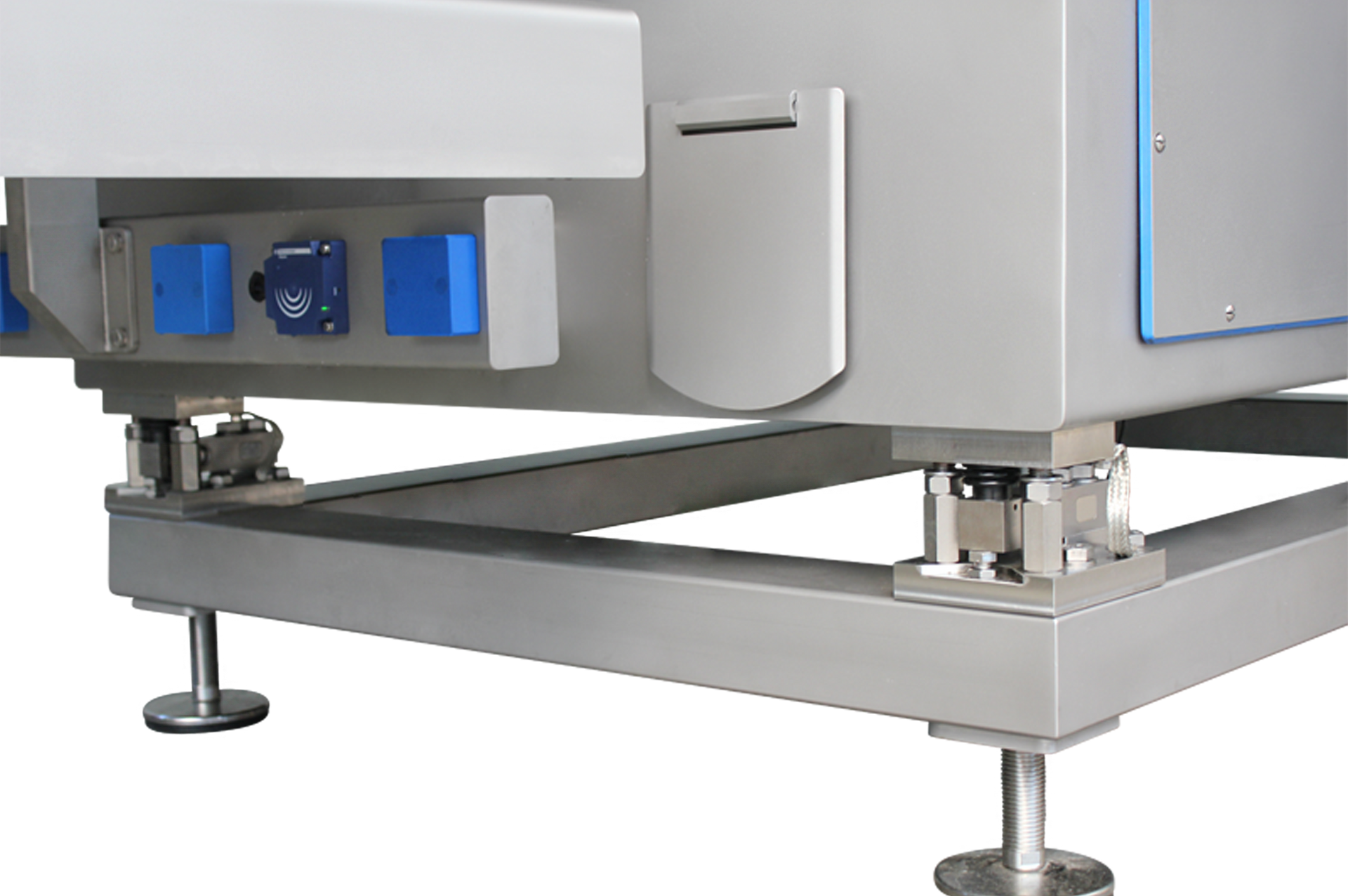

Advanced Programmable Control Panel:

Intuitive touch screen allows operators to create and store custom programs.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

MS

BM

Applications

NOMA Brine Mixers are designed for preparing brine for the injection of a variety of products such as meats, whole poultry and poultry parts, as well as fish and fish fillets. It is also suitable for use in tumbling/marination as well as any other application for which brine is used.

Clarion Locker

"Before the NOMA injector, we spent two grueling days on manual brine injection. Now, it’s down to under an hour—and the results are so impactful, my wife jokes that she’d rather give me up than give up this machine.” – Owner

You Might Also Like

Introduction to Industrial Brine Mixers

What is a brine mixer and why is it important in food processing?

A brine mixer is a specialized piece of industrial food processing equipment designed to prepare homogenous brine solutions—mixtures of water, salt, and other ingredients—used for injection and marination of meat, poultry, and seafood products. The primary function of a brine mixer is to ensure that all dry and liquid ingredients are thoroughly blended, resulting in a consistent brine solution that can be reliably used in further processing steps. This consistency is crucial for achieving uniform product quality, flavor, and preservation, as well as for meeting food safety standards. In meat, poultry, and seafood processing, the use of a brine mixer helps improve product texture, juiciness, and shelf life, while also supporting efficient and hygienic production workflows.

How do the Series MS and BM models support efficient brine preparation?

The Series MS and BM industrial brine mixers from BAK Food Equipment are engineered to meet the demands of high-capacity food production environments. Both models are constructed entirely from stainless steel, ensuring durability and long-lasting performance even under rigorous use. The mixing system features mechanical agitators that rapidly and efficiently blend dry ingredients into water, creating a homogenous brine solution in a short time. An integrated centrifugal pump further enhances the mixing process and allows for easy transportation of the prepared brine to other equipment, such as brine injectors.

Key Features of the BAK Brine Mixers

What are the main features of the MS and BM series?

The MS and BM series brine mixers from BAK Food Equipment are engineered to deliver reliable, efficient, and hygienic brine preparation for food processing applications. BAK's single unit brine mixers are available in a range of capacities, from 250 to 2,000 liters, making them suitable for operations of various sizes. The core features include robust mechanical agitators that ensure rapid and uniform mixing of salt and dry ingredients into water, resulting in a consistently homogenous brine solution. Each unit is equipped with a centrifugal circulation pump, which not only guarantees thorough blending but also facilitates the easy transfer of brine to other processing equipment, such as brine injectors.

The BM series offers additional advanced features, including a CIP (Clean-In-Place) integrated automatic washing system. This system uses a uniquely designed swivel head to provide quick, complete, and efficient cleaning of the tank interior. The BM series also includes a recipe management option, which guides operators through each step of the brine preparation process, ensuring that the correct ingredients are added in the right order for every batch. Both the MS and BM series are constructed entirely from stainless steel, ensuring durability, corrosion resistance, and long-lasting performance in demanding industrial environments. An advanced programmable control panel with an intuitive touch screen allows operators to create, store, and recall custom mixing programs, further enhancing operational efficiency and reducing the risk of human error.

How do these features enhance efficiency, safety, and product consistency?

The design and technology integrated into the MS and BM series brine mixers directly contribute to improved brine mixing efficiency, safety, and product consistency. Mechanical agitators and centrifugal pumps work together to minimize mixing times and guarantee a uniform brine solution, which is critical for consistent product quality in meat processing and other food applications. The programmable control panel reduces manual intervention, streamlines the mixing process, and allows for precise replication of recipes, minimizing the risk of operator error and ensuring batch-to-batch consistency.

Applications in Meat, Poultry, and Seafood Processing

What types of food products can be processed with the help of brine mixers?

Brine mixers are essential in the preparation of brine solutions for a wide range of food products, particularly in the meat, poultry, and seafood industries. These mixers are designed to handle the preparation of brine for injection and marination of red meats, whole poultry and poultry parts, as well as whole fish and fish fillets. By ensuring a homogenous brine solution, these mixers help processors achieve consistent product quality, flavor, and preservation across different protein types.

How do processors use brine mixers in different production lines?

In modern food processing facilities, brine mixers are integrated into various stages of the production line to maximize efficiency and product quality. For meat, whole poultry, poultry parts, and seafood the prepared brine is often injected directly into the product using brine injectors. This process enhances moisture retention, flavor distribution, and shelf life.

Brine mixers are also used in conjunction with tumblers. After brine preparation, the solution can be added to tumblers where meats, poultry, or seafood are gently massaged, improving tenderness, flavor penetration, and overall yield. The integration of brine mixers with brine injectors and tumblers allows for seamless, automated production line operation, reducing manual handling and ensuring consistent results.

Food Safety and Compliance Standards

How do brine mixers help processors meet safety and regulatory standards?

Brine mixers play a critical role in helping food processors meet and exceed compliance with stringent safety and regulatory standards such as HACCP, USDA, and FDA requirements. BAK Food Equipment’s brine mixers are designed with food safety as a top priority, ensuring that every batch of brine meets the highest microbiological safety standards. The integration of a CIP (Clean-In-Place) automatic washing system in the BM Series guarantees thorough and efficient cleaning of the internal surfaces of the brine tank. This system minimizes the risk of contamination and supports consistent hygienic mixing, which is essential for and meeting food processing standards.

What design features support hygienic and safe operation?

Several advanced design features in BAK Food Equipment’s brine mixers support hygienic and safe operation. The mixers are constructed entirely from stainless steel, a material known for its durability and resistance to corrosion, which prevents contamination and supports sanitary operation. The CIP-integrated automatic washing system uses a uniquely designed swivel head to ensure all internal surfaces are cleaned quickly and thoroughly, reducing downtime and manual labor while maintaining high food safety standards. Additionally, the recipe management option in the BM Series provides operators with clear, step-by-step instructions, ensuring consistent brine formulations and reducing the risk of human error. Automated controls and intuitive touch screens further minimize manual handling, lowering the risk of cross-contamination and supporting overall food safety.

Benefits for Food Processors

What are the key benefits of investing in Series MS & BM brine mixers?

Investing in Series MS & BM brine mixers from BAK Food Equipment delivers a range of advantages for food processors seeking to optimize their operations. These mixers are engineered with mechanical agitators and efficient centrifugal pumps, ensuring a homogenous brine solution in a short time. This consistency is crucial for maintaining uniform flavor, texture, and moisture across every batch, which directly enhances product quality and consumer satisfaction. The durable, all-stainless steel construction guarantees reliable performance even in the most demanding environments, making these mixers a long-term asset for any processing facility. Additionally, the BM Series features a CIP-integrated automatic washing system, which upholds the highest standards of hygiene and microbiological safety, further protecting product integrity.

How do they improve production efficiency and ROI?

Series MS & BM brine mixers are designed to streamline production and maximize return on investment (ROI) through several key features. Programmable controls and an advanced touch screen interface reduce labor costs and minimize dependency on highly skilled operators by allowing for easy recipe management and repeatable processes. The integration of automated mixing systems and clear, step-by-step recipe instructions ensures that each batch is prepared accurately, reducing the risk of costly errors. Easy cleaning and low-maintenance design minimize downtime, keeping production lines running smoothly and efficiently. By improving brine mixing efficiency and ensuring consistent product quality, these mixers contribute to yield improvement and extended shelf life, both of which are critical for boosting food processing ROI. The robust construction and thoughtful engineering of the Series MS & BM mixers make them a reliable choice for processors looking to enhance productivity and profitability.

Choosing the Right Brine Mixer

What are the differences between MS and BM series brine mixers?

When selecting a brine mixer for your food processing operation, understanding the distinctions between the MS and BM series is essential. MS brine mixers are core models designed for efficient, high-capacity brine mixing. They feature robust mechanical agitators that ensure a homogenous brine solution in a short time, making them ideal for operations that require reliable and consistent mixing. The MS series also includes a centrifugal brine circulation system, which uses a powerful pump to blend dry ingredients with water and allows for easy transportation of the prepared brine.

The BM brine mixer builds on the core technology of the MS brine mixer with advanced features tailored for operations that prioritize hygiene and process consistency. The BM series is equipped with a CIP-integrated automatic washing system, which guarantees the highest standards of machine hygiene and microbiological safety. This system uses a uniquely designed swivel head for quick and thorough cleaning of the tank interior. Additionally, BM mixers include a recipe management option, providing operators with step-by-step instructions to ensure the correct brine recipe is followed every time.

Which type is best suited for specific processing needs?

The choice between MS and BM brine mixers depends on your specific processing requirements. If your operation requires a straightforward, efficient mixing process, the MS series is an excellent choice. Its mechanical agitators and circulation system are well-suited for preparing brine for injection into meats, poultry, fish, and for use in marination applications.

For facilities where hygiene, recipe consistency, and automation are top priorities, the BM series stands out. The integrated CIP cleaning system and recipe management features make it ideal for processors who require ultra-repeatable, high-quality results. The BM series is particularly beneficial in environments where frequent changeovers or strict sanitation protocols are necessary.

When choosing a brine mixer, consider your daily production needs, available floor space, and the frequency of recipe changes or cleaning cycles. Selecting the appropriate capacity ensures efficient operation, minimizes downtime, and supports consistent product quality across your processing line. Smaller operations or those with limited space may find the MS 250 or MS 400 models suitable, while larger facilities with higher throughput demands can benefit from the MS 1000, MS 1500, or MS 2000 models. Similarly, the BM series is available in 1,000-liter and 2,000-liter capacities, catering to medium and large-scale processors who require advanced features.

Why Choose BAK Food Equipment

Why should processors consider the MS or BM series for their operations?

The MS and BM series of industrial brine mixers from BAK Food Equipment offer a compelling combination of durability, efficiency, and hygienic design, making them an excellent choice for food processors seeking reliable brine preparation systems. Constructed entirely from stainless steel, these mixers are built to withstand the rigors of demanding production environments, ensuring long-lasting performance. The mechanical agitators and centrifugal brine circulation system guarantee a homogenous brine solution in a short time, while the advanced programmable control panel allows operators to create and store custom programs for consistent results. For processors prioritizing food safety, the BM series features a CIP-integrated automatic washing system, which ensures the highest standards of hygiene and microbiological safety. Additionally, the recipe management option streamlines the brine preparation process, reducing the risk of operator error and supporting compliance with food safety standards.

How do these mixers fit into a modern food processing line?

The MS and BM series brine mixers are designed for seamless integration into modern food processing lines. Their versatility makes them suitable for a wide range of applications, including the preparation of brine for injection into meats, whole poultry, poultry parts, fish, and fish fillets, as well as for marination processes. The mixers can be easily connected to brine injectors and other food processing equipment, supporting automated production lines and enhancing overall operational efficiency. With available options such as load cells, water dosage systems, buffer tanks, and SCADA monitoring, these mixers can be tailored to meet specific production needs and capacities, ensuring optimal performance for both small and large-scale operations.

Frequently Asked Questions About our Brine Mixers

What is the difference between the Series MS and BM brine mixers?

The Series MS brine mixers are engineered for efficient brine preparation, featuring robust mechanical agitators and a centrifugal circulation pump to ensure a homogenous brine solution in a short time. These mixers are ideal for seamless integration with brine injectors, making them suitable for a wide range of food processing applications. The Series BM mixers build upon these features by adding advanced options such as an integrated CIP (Clean-in-Place) washing system and recipe management software. The CIP system ensures the highest standards of hygiene by thoroughly cleaning the interior of the tank, while the recipe management option guides operators through each step of the brine preparation process for consistent results and improved food safety.

How do brine mixers improve consistency in meat, poultry, and seafood processing?

Brine mixers play a crucial role in ensuring that salt, seasonings, and other dry ingredients are evenly distributed throughout the brine solution. This uniformity is essential for achieving consistent flavor, moisture retention, and yield in meat, poultry, and seafood products. Whether the brine is used for injection or marination, a well-mixed solution guarantees that every portion of the product receives the intended treatment, resulting in higher quality and more predictable outcomes.

Why is stainless steel construction important for brine mixing equipment?

Stainless steel is the material of choice for brine mixing equipment due to its resistance to corrosion and bacterial growth, as well as its ability to withstand the demanding conditions of industrial food processing environments. This construction ensures long-lasting durability, simplifies cleaning and maintenance, and supports compliance with stringent food safety standards such as HACCP, USDA, and FDA. By using stainless steel, BAK Food Equipment’s brine mixers provide processors with reliable, hygienic, and easy-to-maintain solutions.

How does the CIP system in the BM Series support food safety?

The BM Series brine mixers are equipped with a CIP (Clean-in-Place) system that utilizes a uniquely designed swivel head to wash the inside of the tank quickly and thoroughly. This automated cleaning process guarantees microbiological safety by removing residues and potential contaminants between batches. The CIP system not only reduces downtime but also helps processors maintain regulatory compliance and consistently meet high standards of hygiene.

What capacities are available for Series MS & BM brine mixers?

BAK Food Equipment offers the Series MS brine mixers in capacities ranging from 250 to 2,000 liters, while the BM Series is available in larger sizes of 1,000 and 2,000 liters. This range of capacities allows food processors to select the right mixer based on their production scale and specific application needs, whether preparing brine for small batches or large-scale operations.

For more information about our brine mixers and to explore our full range of Brine Preparation Systems, visit our Brine Preparation Systems page.