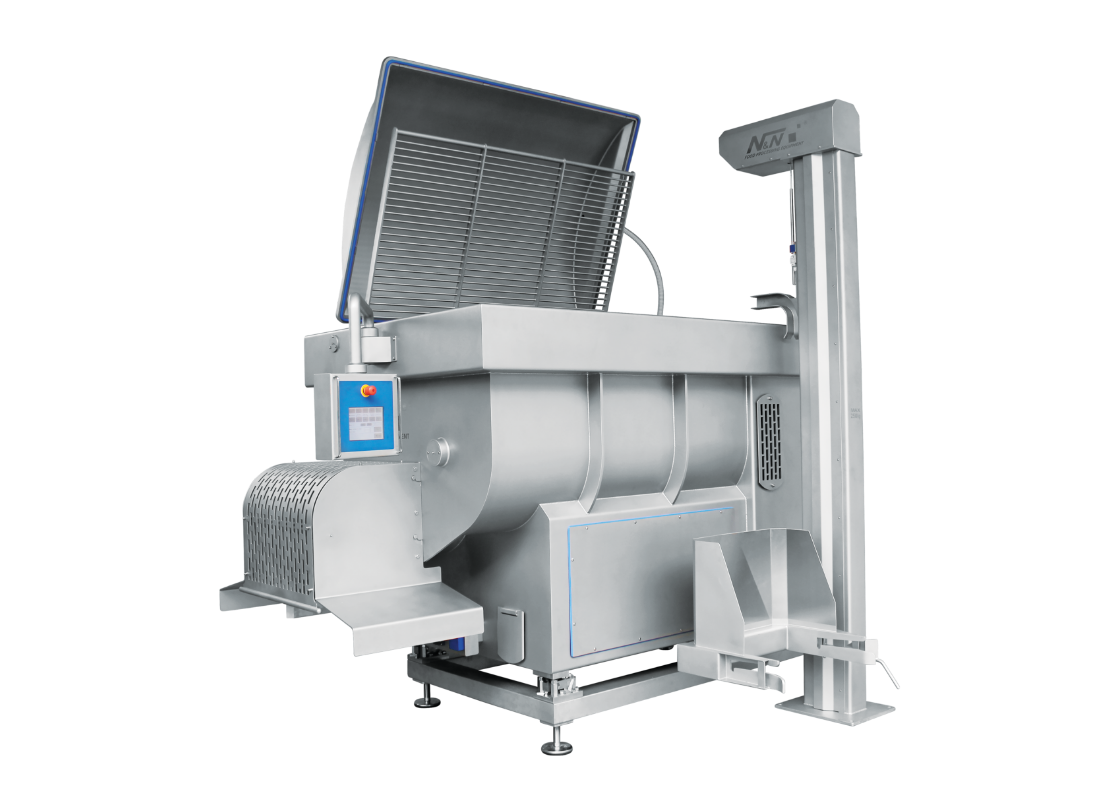

Series MK

High-Efficiency Automated Smoke Stick Washer

Efficiency

Up to 600

Smoke Sticks Per Hour

- Efficient Cleaning for Multiple Tools: The Smoke Stick Washer equipped with a perforated drum, efficiently cleans smoke sticks, slaughter hooks, and other essential food processing equipment. It ensures hygienic, thorough cleaning, making it a reliable solution.

- Automated Washing Control Option: Allows operators to automatically control variables such as washing cycle, chemical concentration, and water dosage.

Why Choose BAK

Durable, Industrial-Grade Construction:

The washer features a compact drum construction made from stainless steel, ensuring durability and long-lasting performance.

Advanced Programmable Control Panel:

Washers offer on-machine button controls for straightforward operation, with a programmable cycle control option that allows operators to adjust settings directly on the controller.

Easy Cleaning and Maintenance:

Thoughtfully designed to make routine cleaning and maintenance straightforward and efficient.

Technical Information

Applications

Smoke stick washers are designed for thorough cleaning of smoke sticks, slaughter hooks, and other essential food processing equipment used in food processing. These washers ensure the removal of residue, grease, and contaminants, helping maintain high hygiene standards in meat processing and smoking operations. Ideal for ensuring equipment cleanliness, they improve efficiency, reduce manual cleaning efforts, and support compliance with stringent food safety regulations.

Snack Stick Case Study

"Before we brought in BAK’s intermeshing paddle mixers, our equipment just couldn’t keep up with what snack sticks demand—the texture was soft, the ‘snap’ wasn’t there, and every batch felt like a gamble. Now, with proper protein extraction and fast, consistent mixing, we’re turning out firm, evenly colored snack sticks we’re proud of. The results gave us the confidence to refocus our portfolio around snack sticks and keep investing in additional mixing and grinding equipment across our plants—it’s reshaped our business." – Leadership team

You Might Also Like

Efficient Cleaning for Food Processing Equipment

What is the Series MK Smoke Stick Washer used for?

The Series MK Smoke Stick Washer is an industrial-grade cleaning solution specifically engineered for the thorough cleaning of smoke sticks, slaughter hooks, and other essential tools used in food processing environments. Its robust, stainless steel construction and perforated drum design allow it to efficiently clean up to 600 smoke sticks per hour, making it an indispensable asset for facilities that require high-throughput sanitation of equipment exposed to meat, smoke, and other food residues.

How does it support food safety and production efficiency?

The Series MK Smoke Stick Washer plays a critical role in maintaining food safety compliance by ensuring that all smoke sticks and related equipment are hygienically cleaned, removing residue, grease, and contaminants that could compromise product quality or safety. The automated cleaning process reduces manual labor, minimizes the risk of human error, and supports HACCP compliance by providing consistent, repeatable cleaning cycles. Operators can control variables such as washing cycle duration, chemical concentration, and water dosage through an advanced programmable control panel, further enhancing both sanitation and operational efficiency. The easy-to-clean and maintain design also reduces downtime, supporting continuous production.

What industries benefit from this solution?

Industries that benefit most from the Series MK Smoke Stick Washer include meat processing, smoked meat production, and any food processing operation that relies on smokehouse equipment and requires rigorous sanitation protocols. By automating the cleaning of smoke sticks and slaughter hooks, these industries can achieve higher standards of meat processing sanitation, reduce manual cleaning efforts, and ensure compliance with stringent food safety regulations. The washer is particularly valuable for facilities seeking to streamline their cleaning processes while upholding the highest levels of hygiene and efficiency.

Key Benefits – Why Choose the Series MK

What makes this washer more valuable than manual cleaning?

The Series MK Smoke Stick Washer offers a significant upgrade over manual cleaning by automating the entire process. With its perforated drum and advanced programmable control panel, the washer ensures every smoke stick, slaughter hook, and piece of essential food processing equipment is cleaned thoroughly and consistently. This automation reduces manual cleaning labor by up to 75%, freeing operators to focus on core production tasks rather than repetitive, labor-intensive cleaning.

How does it enhance production efficiency and ROI?

The Series MK is engineered for high throughput, capable of processing up to 600 smoke sticks per hour. This level of efficiency is unattainable with manual methods, allowing processors to keep pace with demanding production schedules. The washer’s closed-loop filtration system minimizes water and energy usage, directly reducing utility costs and contributing to cost savings in food processing. By delivering consistent, repeatable wash cycles, the Series MK ensures that equipment is always ready for use, minimizing downtime and maximizing return on investment.

What specific problems does it solve for processors?

Processors face several challenges, including labor shortages, inconsistent cleaning results, and the need to meet stringent food safety regulations. The Series MK addresses these issues by automating the cleaning process, ensuring every item is washed to the same high standard every time. High-temperature washing and precise chemical dosing minimize contamination risks, helping processors meet and exceed HACCP sanitation requirements. The washer’s stainless steel construction guarantees long-term reliability, even in demanding industrial environments, while its user-friendly design makes routine cleaning and maintenance straightforward. Ultimately, the Series MK solves the dual challenge of maintaining high hygiene standards and operational efficiency in modern food processing facilities.

Advanced Features and Technology

What features make the Series MK stand out?

The Series MK Smoke Stick Washer distinguishes itself through a combination of advanced engineering and user-focused design. At its core is a perforated drum technology that ensures maximum water impingement on all surfaces of smoke sticks, slaughter hooks, and other essential food processing equipment. The washer’s compact stainless steel construction provides long-term durability and allows for easy integration into existing food processing lines, making it a reliable choice for facilities seeking to enhance their cleaning operations with industrial washer features.

How does the control system simplify operation?

The Series MK is equipped with an advanced programmable control panel, offering both on-machine button controls for straightforward use and a programmable cycle control option. Operators can select from multiple pre-set wash recipes, such as Heavy Duty Smoke Resin or Standard Hook Cleaning, enabling one-touch operation and consistent, repeatable results. The automated washing control system further streamlines the process by allowing automatic adjustment of washing cycle duration, chemical concentration, and water dosage. This level of automation not only reduces the potential for human error but also supports food manufacturing efficiency by minimizing manual intervention and ensuring optimal cleaning performance every cycle.

What makes the cleaning action effective yet gentle?

The effectiveness of the Series MK’s cleaning action lies in its perforated drum washer design, which maximizes water contact with all surfaces while maintaining a gentle approach to protect delicate equipment. The drum’s rotation and water impingement work together to remove residue, grease, and contaminants without causing wear or deformation to smoke sticks and hooks. Additionally, the washer is designed for easy cleaning and maintenance, supporting ongoing hygiene and compliance with food safety standards. For facilities focused on sustainability, the Series MK offers an optional closed-loop filtration system, which reduces water and energy consumption without compromising cleaning results.

Smoke Stick Washer FAQs

What does a smoke stick washer clean?

A smoke stick washer is specifically designed to clean smoke sticks, slaughter hooks, and other essential tools used in meat processing and smoking operations. Its primary function is to remove residue, grease, and contaminants from these items, ensuring they meet the high hygiene standards required in food processing environments.

How many smoke sticks can the washer clean per hour?

The Series MK Smoke Stick Washer from BAK Food Equipment is engineered for efficiency, capable of cleaning up to 600 smoke sticks per hour. This high throughput makes it an excellent choice for both medium and large-scale production facilities, where maintaining a steady workflow and minimizing downtime are critical.

Is the Smoke Stick Washer made from stainless steel?

Yes, the smoke stick washer features a fully stainless-steel construction. This industrial-grade material ensures the washer is durable, resistant to corrosion, and easy to sanitize. The robust design supports a long service life, even in demanding food processing environments.

Can the washing cycle be automated?

Absolutely. The washer offers automated control over key variables such as washing time, water dosage, and chemical concentration. Operators can use the advanced programmable control panel to adjust these settings, ensuring consistent and reliable cleaning results with minimal manual intervention.

What are the benefits of using an automated smoke stick washer?

Using an automated smoke stick washer provides several advantages: it reduces labor requirements, improves cleaning consistency, and supports HACCP compliance. Automation also enhances overall production efficiency by streamlining the cleaning process and minimizing the risk of human error.

Can this washer be used for other processing tools besides smoke sticks?

Yes, the washer is versatile and can effectively clean not only smoke sticks but also slaughter hooks and other food processing equipment that require hygienic washing. This flexibility makes it a valuable addition to any facility focused on maintaining strict cleanliness standards.