Understanding Food Processing Equipment: Key Types and Applications

Selecting the right equipment is one of the most vital steps in securing a smooth, efficient food production process. Whether you’re launching a new facility or considering an upgrade, understanding food processing equipment — from mixers to packaging systems — is essential for reaching your production goals and maintaining quality. Let’s look at the most common types of food processing equipment and discover how advanced solutions uplift operations across the food industry.

What Is Food Processing Equipment?

Food processing equipment refers to the machines and tools used to transform raw ingredients into finished food products. These systems automate, standardize, and streamline tasks such as cutting, grinding, mixing, cooking, and packaging, ensuring consistent results and higher productivity.

When you invest in quality food processing equipment, you’re not just purchasing machines — you’re securing the backbone of your operations. Proper equipment supports food safety, enhances efficiency, and helps your team maintain high product standards.

Categories and Functions of Core Processing Equipment

Knowing which equipment is used for processing various food products helps you navigate the industry’s requirements and select assets that align with your goals. Below, you’ll find a breakdown of the major categories.

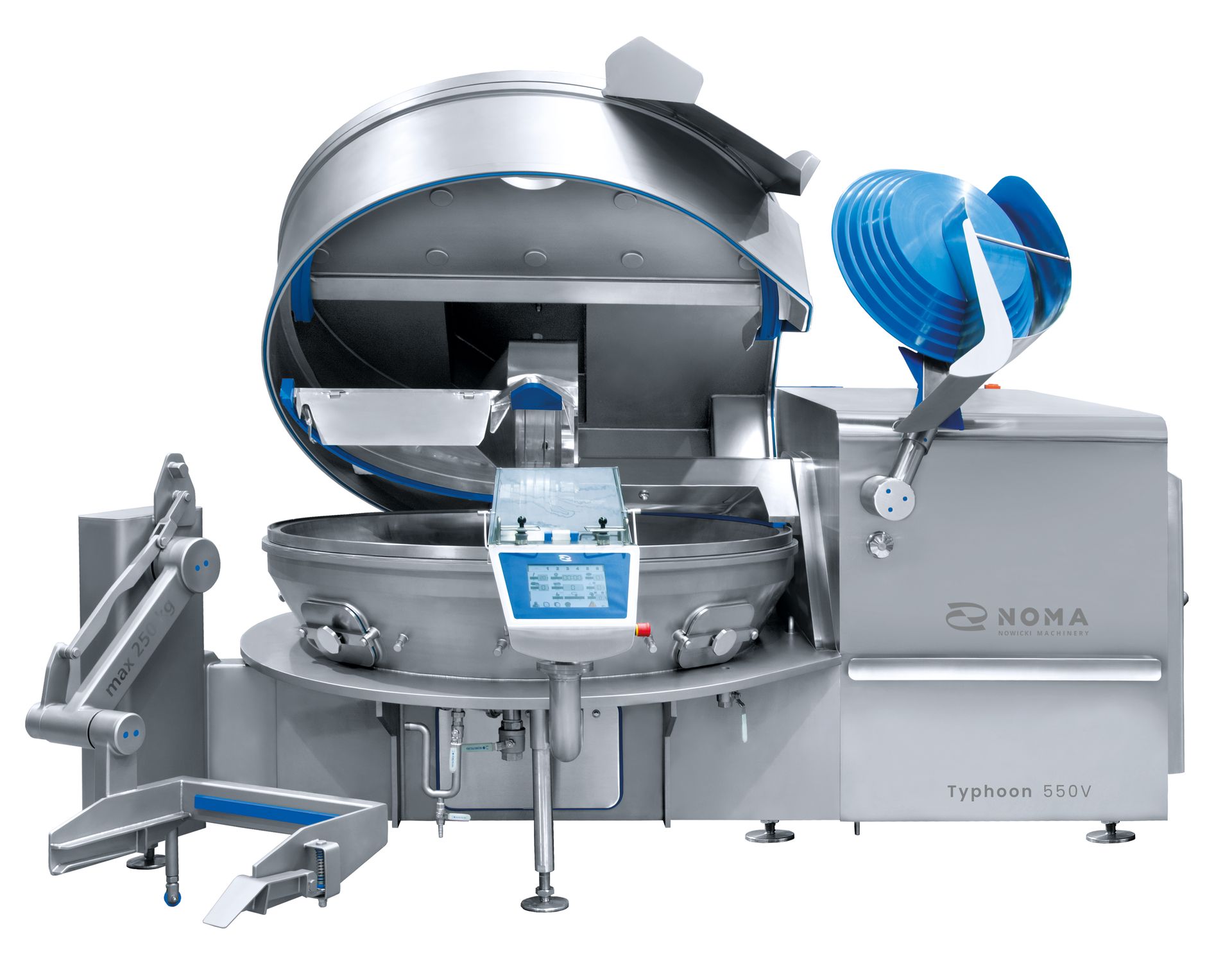

Mixing Equipment

Mixers are essential in both small- and large-scale food operations. They’re designed to evenly combine ingredients, whether you’re working with dough, meat blends, sauces, or seasonings. Modern food mixing machine technologies feature programmable mixing cycles and hygienic designs, giving you control over product texture and consistency.

Grinding and Cutting Machines

Grinders and slicers play a crucial role in preparing meats, vegetables, and other ingredients to precise specifications. For example, an industrial meat grinder streamlines bulk meat preparation, ensuring uniformity for sausages, burgers, or deli items. Many facilities also use bowl cutters, food emulsifiers, and flaker equipment to achieve the desired ingredient size and structure.

Conveyors and Handling Systems

Conveyor systems move products through the processing line quickly and safely. Automated conveyors decrease manual handling, limit contamination risks, and improve line efficiency. Loader and transfer equipment, such as loader equipment, bridges gaps between processing steps, optimizing flow and reducing labor demands.

Tumbling, Injecting, and Marinating

To distribute seasonings or brines and enhance product texture, processors rely on machines like vacuum tumblers and brine injectors. These devices infuse flavors or solutions evenly and can significantly reduce marination times while ensuring food safety by minimizing manual intervention.

Cooking, Smoking, and Baking Systems

Specialized equipment like ovens, steamers, and smoke chambers cook or smoke food products consistently and safely. In the bakery sector, ovens and proofers are indispensable for mass-producing bread, pastries, and other baked goods.

Washing and Sanitizing Systems

Cleanliness is non-negotiable in the food industry. Food washer machines, designed for cleaning produce or equipment, help meet strict hygiene standards and support product shelf life.

Packaging Equipment

Automated packaging systems ensure products are safely sealed, labeled, and ready for distribution. These systems may include vacuum packaging, sealing, labeling, and coding — all critical for compliance and customer satisfaction.

The Role of Advanced Equipment in Operational Efficiency

With modern food industry processing equipment, you gain more than speed. Automated, connected systems improve consistency, reduce downtime, save on labor, and adapt to changing product demands.

Technology advances, such as programmable controls and data tracking, enable real-time adjustments and better decision-making.

Integrating food industry automation further lifts efficiency, streamlining everything from ingredient batching to final packaging. These solutions are essential for facilities aiming to scale up production and maintaincompetitive quality.

How BAK Food Equipment Helps You Choose the Right Solution

Navigating the wide array of available systems can be overwhelming. At BAK Food Equipment, our team partners with you from the earliest consultation to final installation. We begin by understanding your products, throughout requirements, and facility constraints, then recommend equipment or complete lines tailored to your needs — whether you’re looking for a standalone food grinder machine or a custom, multi-stage processing line.

But our support doesn’t end with installation. We stand by every piece of equipment we provide, offering responsive equipment maintenance to keep you running smoothly and minimize downtime.

Choosing the Best Equipment for Your Process

Selecting processing equipment isn’t just about the machine itself — it’s about finding a reliable partner to guide you, from specifying the right food equipment to ensuring it continues to perform for years. Considerations like safety, space, sanitation, production targets, and product specifications all factor into the final decision.

Our clients benefit from advanced, efficient solutions for every stage of food production — from raw ingredient prep to final packaging — backed by a knowledgeable support team.

Summary: Building a Foundation for Food Processing Success

Understanding food processor equipment and its applications is fundamental to optimizing your operations. Mixing, grinding, slicing, conveying, and packaging systems all play a specialized role in turning ingredients into high-quality products. With reliable and innovative processing solutions from BAK Food Equipment, you have a partner dedicated to your facility’s efficiency, performance, and long-term growth. If you’re exploring new equipment or a full system upgrade, our team is ready to guide you every step of the way.