What is a Vacuum Tumbler?

Introduction to Vacuum Tumblers

What is a vacuum tumbler and how does it work?

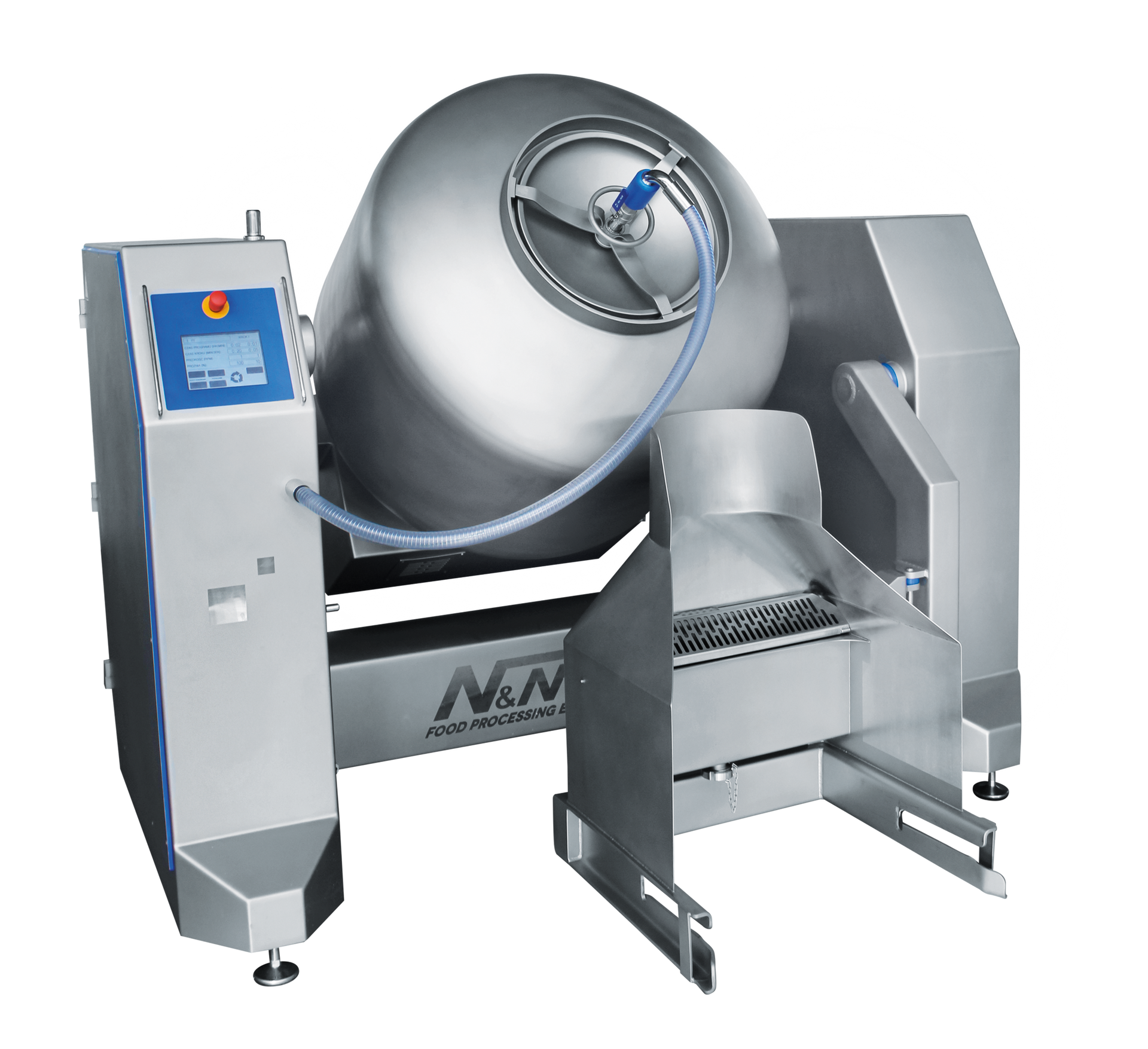

A vacuum tumbler is a specialized piece of meat processing equipment designed to enhance the protein extraction, tenderizing, and marination process by using vacuum technology. In a vacuum tumbler, food products—most commonly meat—are placed inside a rotating drum and the air is then removed from the chamber, creating a vacuum environment. As the drum rotates, the marinade is more effectively drawn into the product, allowing for deeper flavor infusion and improved moisture retention. This vacuum tumbling process not only accelerates marination but also effectively extracts proteins and tenderizes the product.

Why are vacuum tumblers important in food processing?

Vacuum tumblers play a significant role in modern food processing by maximizing the quality, flavor, color, and texture of various products. By removing air and applying gentle mechanical action, vacuum tumblers help extract proteins, marinate, and tenderize products, ensuring consistent flavor distribution, improved texture, and enhanced moisture retention. This process also increases product yield, making it a valuable tool for processors seeking to deliver cost-effective, consistent, high-quality results. The use of vacuum tumblers is especially important for processors who need to meet high production demands while maintaining product quality and efficiency.

How do vacuum tumblers differ from traditional marination methods?

Traditional marination methods typically involve soaking meat in a marinade for extended periods, relying on passive diffusion to infuse flavors. In contrast, vacuum tumblers use advanced marination techniques that combine vacuum technology with mechanical action to significantly reduce marination time and improve results. The vacuum environment opens up the meat’s fibers, allowing the marinade to penetrate more deeply and quickly. This results in superior flavor infusion, enhanced food texture, and more consistent product quality compared to traditional methods. Vacuum tumblers are an essential advancement for processors looking to optimize their marination processes and deliver better-tasting, higher-quality products.

Benefits of Vacuum Tumbling

How does vacuum tumbling enhance meat flavor and texture?

Vacuum tumbling is a highly effective meat marination technique that significantly improves both flavor and texture. By placing meat and marinade inside a sealed drum and applying a vacuum, the process removes air from the product and the environment. This creates a pressure differential that opens up the meat’s muscle fibers, allowing the marinade to penetrate deeply and evenly. The result is superior flavor infusion and a more tender texture compared to traditional marination methods.

The tumbling action also helps to distribute the marinade uniformly, ensuring consistent quality throughout the batch.

What are the vacuum marination benefits?

Vacuum marination offers several key benefits over conventional marination. One of the most notable advantages is the reduction in marination time—what might take hours or overnight with traditional methods can be achieved more effectively in minutes with vacuum tumbling. This efficiency is due to the enhanced marinade absorption, as the vacuum environment forces the marinade into the meat more rapidly and thoroughly. Additionally, vacuum marination results in deeper flavor infusion and improved moisture retention, which translates to juicier, more flavorful products. For food processors, this means increased product yield and more consistent results, making vacuum tumbling an essential tool for modern meat processing operations.

How does vacuum tumbling contribute to food safety compliance?

Vacuum tumbling plays a crucial role in helping processors meet food safety standards. The controlled environment inside the tumbler minimizes the risk of contamination by reducing exposure to air and potential pathogens. Furthermore, the even distribution of marinade, which often contains salt and other preservatives, helps inhibit bacterial growth throughout the product. By streamlining the marination process and reducing handling, vacuum tumbling supports food safety compliance and helps processors adhere to strict industry regulations. BAK Food Equipment’s range of tumbling solutions, from classic tumblers to fully automated tumbling lines, are designed to support processors in maintaining high standards of food safety while optimizing product quality.

Vacuum Tumbler Maintenance and Care

How to properly maintain a vacuum tumbler?

Proper maintenance of a vacuum tumbler is essential to ensure optimal performance, product quality, and food safety compliance in industrial food processing environments. Begin by following the our recommended cleaning schedule included in the product manual, which involves putting the tumbler through a washing cycle with water and cleaning agents. We also recommend having our service technicians periodically maintenance the machine to make sure that everything is in good standing.

Why is regular maintenance important for vacuum tumblers?

Regular maintenance is crucial for extending the lifespan and efficiency of vacuum tumblers, which are vital pieces of meat processing equipment. Well-maintained tumblers ensure consistent marination, flavor, and moisture retention, directly impacting product yield and quality. Neglecting maintenance can lead to costly repairs, unplanned downtime, and compromised product safety. By investing in a proactive maintenance program, processors can maximize equipment uptime, protect their investment, and deliver high-quality marinated products to the market.

Comparing Marination Techniques

How does vacuum tumbling compare to traditional marination techniques?

Vacuum tumbling stands out among meat marination techniques for its ability to deliver rapid and uniform marinade absorption compared to traditional soaking methods. Traditional soaking relies on passive diffusion, which can take hours or even days for the marinade to penetrate the meat, often resulting in uneven flavor distribution and inconsistent product quality.

In contrast, the vacuum tumbling process uses a rotating drum under vacuum pressure to open up the meat’s muscle fibers, allowing the marinade to penetrate deeply and evenly throughout the product. This not only accelerates the marination process but also enhances flavor infusion and food texture enhancement. BAK Food Equipment offers a range of tumbling solutions, from classic tumblers to fully automated tumbling lines, designed to maximize the quality and color of marinated products for processors seeking efficiency and consistency.

What makes vacuum tumbling more effective for marinade absorption?

The science behind vacuum tumbling’s effectiveness lies in the combination of mechanical action and vacuum pressure. When meat is placed in a vacuum tumbler, the removal of air causes the muscle fibers to expand, creating more space for the marinade to enter. As the drum rotates, the tumbling action massages the marinade into the meat, ensuring thorough and uniform distribution. This advanced marination technique increases marinade absorption and improves moisture retention, resulting in a juicier, more flavorful final product. The process is highly efficient, often reducing marination times from several hours to minutes, while delivering superior product yield and quality.

Are there any disadvantages to using vacuum tumblers for marination?

While vacuum tumbling offers significant advantages in terms of speed, consistency, and flavor infusion, there are some potential drawbacks to consider. The initial investment in vacuum tumbling equipment can be higher than traditional methods. However, for most commercial meat processing applications, the benefits of vacuum tumbling—such as enhanced marinade absorption, improved product quality, and increased efficiency—far outweigh the initial cost of entry.

Industrial Applications of Vacuum Tumblers

In what industrial settings are vacuum tumblers most commonly used?

Vacuum tumblers are essential in a variety of industrial food processing environments, particularly within the meat and poultry sectors. These machines are widely used by processors who require consistent marination, flavor infusion, and moisture retention across large batches of product. Vacuum tumbling also supports protein extraction, allowing for the creation of hams and other deli meats. Beyond meat processing, vacuum tumblers are also found in seafood, ready-to-eat meals, pet food, and plant-based items, where uniform flavor distribution and texture are critical. Their versatility makes them a staple in facilities that prioritize high product quality and efficient throughput.

How do vacuum tumblers fit into the larger food processing workflow?

Within the broader context of industrial food processing, vacuum tumblers serve as a key step in the preparation and marination phase. Product and marinade are loaded into the tumbler where vacuum technology is applied. This process accelerates the absorption of marinades and seasonings, ensuring even distribution and enhanced flavor. Vacuum tumblers can be integrated into semi-automated or fully automated production lines, streamlining operations and supporting food safety compliance by reducing manual handling and exposure to contaminants. Their role is pivotal in maintaining consistency and quality before products move on to packaging, or cooking stages.

What are the scalability and efficiency benefits of using vacuum tumblers in industrial settings?

Vacuum tumblers offer significant scalability and efficiency advantages for industrial food processors. Their ability to handle large volumes of product in a single cycle reduces labor requirements and shortens marination times compared to traditional methods. Automated and semi-automated tumbling lines from BAK Food Equipment further enhance throughput, allowing processors to meet high production demands without sacrificing product consistency. Ultimately, vacuum tumblers contribute to a more streamlined, cost-effective, and reliable food processing operation.

Vacuum Technology in Food Preservation

How does vacuum technology contribute to food preservation?

Vacuum technology plays a pivotal role in modern food preservation by removing air from the environment surrounding food products. This process significantly slows down the growth of spoilage microorganisms and oxidation reactions that can degrade food quality, color, and nutritional value. By creating a low-oxygen environment, vacuum technology helps maintain the freshness and safety of a wide range of foods, from meats to plants, making it a cornerstone among advanced preservation technology and food preservation methods.

Optimizing Marination Time with Vacuum Tumblers

What is the optimal marination time using vacuum tumblers?

Determining the optimal marination time when using vacuum tumblers depends on several factors, including the type of meat, the size of the cuts, and the desired flavor intensity. Generally, vacuum tumblers significantly reduce the time required for marination compared to traditional methods. While conventional marination can take several hours or even overnight, vacuum tumbling can achieve similar or superior results in minutes. Processors should refer to specific product guidelines, conduct small-scale tests, and work with our specialists to create their own unique recipes for their production needs.

How does vacuum tumbling reduce marination time compared to traditional methods?

The vacuum tumbling process accelerates marination by creating a low-pressure environment inside the tumbler drum. This environment opens up the meat’s muscle fibers, allowing the marinade to penetrate more deeply and rapidly. The mechanical action of the tumbler further enhances this effect by continuously massaging the product, ensuring even distribution of the marinade. As a result, what would typically require several hours in a static marinade can be accomplished in minutes. This marination time optimization not only improves production efficiency but also enhances food texture and flavor infusion, leading to a higher-quality finished product.

Can vacuum tumbling time be adjusted for different types of meat?

Yes, vacuum tumbling time can and should be adjusted based on the type of meat, the size of the pieces, and the desired outcome. For example, larger or denser cuts of meat may require slightly longer tumbling times to achieve optimal flavor infusion and food texture enhancement, while smaller or more delicate cuts may need less time to avoid over-processing. Additionally, the intensity of the marinade and the specific goals—such as maximizing moisture retention or achieving a particular flavor profile—will influence the recommended tumbling duration. Processors can fine-tune their vacuum marination techniques by experimenting with different time settings and monitoring product quality, ensuring that each batch meets their standards for taste, texture, and yield. BAK Food Equipment will also work with you to determine your optimal recipe upon request.

Conclusion: Importance Of Vacuum Tumbling

How does vacuum tumbling revolutionize food processing and marination?

Vacuum tumbling has fundamentally transformed the way food processors approach marination and product preparation. By utilizing advanced vacuum technology, this process creates a low-pressure environment inside the tumbler, optimizing the protein extraction, marination, and tenderizing processes, ensuring consistent flavor distribution, improved texture, and enhanced moisture retention across various food types. This allows processors to create products they wouldn’t be able to create before and improve their existing marinated products. The vacuum tumbling process is especially valuable for processors seeking to maximize the color, texture, and taste of value-added products, setting a new standard for efficiency and product excellence in the industry.

What are the key takeaways regarding the use and maintenance of vacuum tumblers?

To fully benefit from vacuum tumbling, it is essential to select the right equipment and follow best practices for use and maintenance. Regular cleaning and maintenance of the tumbler are crucial for food safety compliance and to maintain optimal performance. Processors should also monitor vacuum levels and tumbling times to achieve the desired results for each product type. BAK Food Equipment offers a comprehensive range of solutions, including Classic Vacuum Tumblers, Tilting Vacuum Tumblers, and Mixing Tilting Tumblers, each designed to meet specific production needs. For larger operations, Semi Automated Tumbling Lines and Fully Automated Tumbling Lines provide scalable options that streamline workflow and enhance productivity.

Why is vacuum tumbling considered a critical technique in modern food processing?

Vacuum tumbling is now recognized as a critical technique in modern food processing due to its ability to meet the evolving demands for quality, efficiency, and food safety. The process not only improves flavor and texture but also helps processors comply with stringent food safety standards. The process also supports protein extraction, allowing for the creation of hams and other deli meats.

As consumer expectations for high-quality, flavorful, and safe products continue to rise, vacuum tumbling stands out as an indispensable tool for processors aiming to stay competitive. BAK Food Equipment’s innovative tumbling solutions empower food manufacturers to achieve consistent results, optimize production, and deliver products that meet the highest industry standards.

In summary, vacuum tumbling is a transformative process that enhances product quality, increases yield, and supports food safety compliance. With the right equipment and maintenance practices, processors can leverage this technology to meet current and future food processing challenges. For more information on the full range of tumbling solutions, explore BAK Food Equipment’s

Classic Vacuum Tumblers,

Tilting Vacuum Tumblers,

Mixing Tilting Tumblers,

Semi Automated Tumbling Lines, and

Fully Automated Tumbling Line.