What is Smoking in Food Processing?

Introduction to Smoking in Food Processing

What is smoking in food processing and how does it contribute to flavor and preservation?

Smoking in food processing is a time-honored culinary technique that involves exposing food—most commonly meats and fish—to smoke generated from burning wood chips or sawdust. This process not only imparts a distinctive smoky flavor and aroma but also serves as an effective method of food preservation. The smoke contains compounds that inhibit the growth of spoilage-causing bacteria and molds, thereby extending the shelf life of smoked foods.

How has smoking evolved as a culinary technique over time?

Historically, smoking was developed as a practical solution for preserving food before the advent of refrigeration. Early societies discovered that exposing meat and fish to smoke helped prevent spoilage, making it possible to store food for longer periods. Over time, smoking evolved from a purely functional preservation method to a celebrated culinary technique.

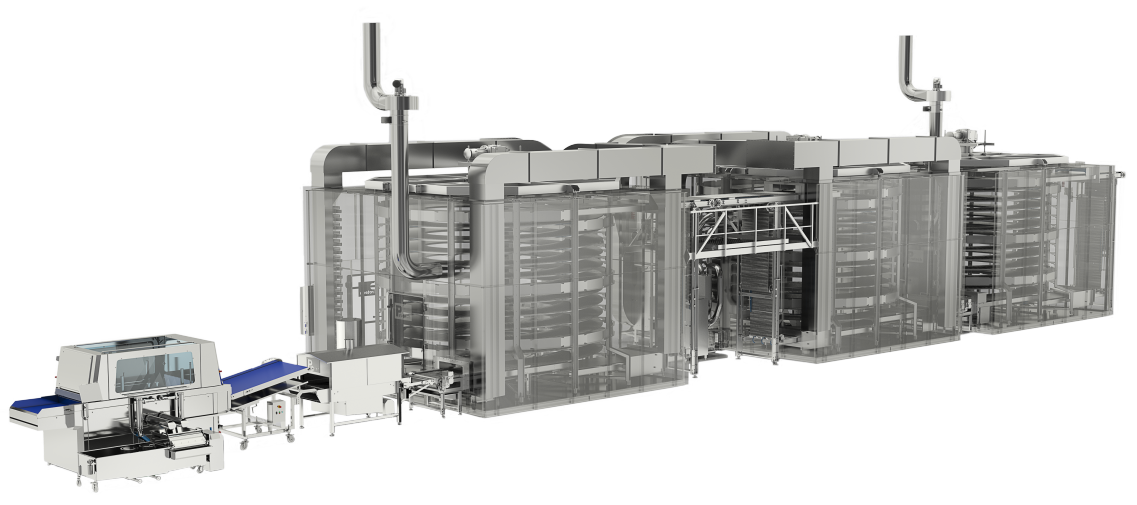

Today, innovations in food processing equipment—such as BAK Food Equipment’s automated spiral smoking and chilling lines—have transformed traditional smoking into a highly efficient, scalable process. These advancements enable producers to create a wide variety of smoked products, from classic smoked meats and fish to cheeses and alternative proteins, while maintaining the authentic flavors that consumers expect.

What are the primary benefits of smoking foods?

The benefits of smoking foods are multifaceted. First and foremost, smoking enhances flavor, infusing products with complex, savory notes that are highly sought after in both traditional and modern cuisines. Additionally, the smoking process contributes to food safety and preservation by reducing moisture content and introducing antimicrobial compounds. This dual action not only extends shelf life but also helps maintain product quality during storage and distribution. The versatility of smoking techniques allows for the production of a diverse range of smoked foods, including bacon, ham, smoked salmon, and even smoked salts and cheeses. With the integration of advanced food processing equipment, manufacturers can achieve greater efficiency, consistency, and product innovation, meeting the evolving demands of the food industry while honoring the rich heritage of smoking as a culinary art.

Differences Between Cold and Hot Smoking

What distinguishes cold smoking from hot smoking?

Cold smoking and hot smoking are two distinct smoking techniques used in food processing, each with unique processes and outcomes. Cold smoking involves exposing foods to smoke at lower temperatures, typically below 90°F, without cooking the product. This method imparts a smoky flavor while preserving the raw texture of foods. In contrast, hot smoking uses higher temperatures, generally above 200°F, which both flavors and cooks the food simultaneously. The choice between these methods depends on the desired end product—cold smoking is needed for foods like raw smoked salmon while hot smoking is needed for foods liked bacon.

How do temperature and time impact the flavor and safety of smoked foods?

Temperature and time are critical factors in both the flavor development and safety of smoked foods. Cold smoking, due to its lower temperatures, requires longer exposure times to achieve the desired smoke flavor. However, because the food remains uncooked, it must be handled with care to prevent the growth of harmful bacteria. Hot smoking, on the other hand, uses higher temperatures that not only infuse smoke flavor but also cook the food, reducing the risk of pathogens. The higher heat also affects the texture, often resulting in a firmer product compared to the softer texture of cold-smoked foods.

Which foods are best suited for cold smoking versus hot smoking?

Certain foods are better suited to one smoking technique over the other. Cold smoking is commonly used for products like smoked salmon, cheeses, and some cured meats, where maintaining a delicate texture and raw quality is desirable. Hot smoking is ideal for items such as bacon, ham, poultry, and sausages, where both flavor and thorough cooking are required. BAK Food Equipment’s smoke chambers and automated spiral smoking systems are designed to accommodate both cold and hot smoking processes, allowing producers to achieve optimal flavor profiles and food safety standards for a wide range of products, from traditional meats to alternative proteins and cheeses. By selecting the appropriate smoking technique, food processors can tailor the texture, flavor, and shelf-life of their smoked foods to meet specific market demands.

Essential Equipment for Smoking Food

What are the must-have pieces of equipment for smoking food professionally?

The right smoking equipment is crucial for achieving authentic smoked flavors and consistent results. BAK Food Equipment offers a comprehensive range of smoked products processing equipment, including automated spiral smoking/cooking/chilling lines, injectors for precise flavor and preservative delivery, and versatile smoke chambers capable of handling meat, seafood, cheese, and alternative proteins. Additional essentials such as brine mixing and preparation systems, tumblers, loaders, and washers streamline the workflow and ensure food safety and quality at every stage.

How does the choice of smoking equipment affect the outcome of smoked dishes?

The type and quality of smoking equipment directly influence smoke distribution, flavor infusion, and overall product consistency. For example, older traditional smokehouses can result in uneven smoke and temperature exposure. Moving to a modern smokehouse, like BAK’s smokehouses, gives processors precise control over smoking parameters, which can greatly improve your quality and consistency. For peak quality and consistency, BAK’s automated smoking spiral systems expose every product to the exact same smoke and temperature conditions, ensuring uniform smoke and temperature exposure. The choice of equipment also determines the efficiency of the smoking process, impacting yield, labor requirements, and operational costs.

What are the latest innovations in smoking equipment?

Recent advancements in smoking technology have focused on automation, energy efficiency, enhanced flavor enhancement, and food preservation. BAK Food Equipment’s patent-pending automated spiral smoking system exemplifies this innovation, offering end-to-end automation that reduces labor expenses, minimizes waste, and increases yields. These systems are adaptable for a wide range of products, from classic smoked meats like bacon to alternative proteins and specialty items like smoked salts and cheeses. Innovations such as phased automation allow producers to scale their investment gradually, while integrated injectors and tumblers ensure consistent flavor infusion and texture improvement. These technological advancements not only streamline production but also help maintain the rich, authentic smoky flavors that consumers expect.

Choosing the Right Wood for Flavor Infusion

How does the type of wood impact the flavor profile of smoked foods?

The type of wood used in the smoking process plays a crucial role in determining the final flavor profile of smoked foods. Each wood species imparts its own unique characteristics, ranging from mild and sweet to bold and robust. For example, fruitwoods like apple and cherry provide a subtle sweetness and delicate aroma. Hardwoods such as hickory and oak deliver a stronger, more pronounced smoke flavor. The moisture content, density, and natural oils in the wood also influence the intensity and complexity of the smoke flavor, allowing processors to tailor the taste experience to specific products.

What are the best woods for smoking meats, fish, and cheeses?

Selecting the best wood for smoking depends on the type of food being prepared and the desired flavor outcome. For smoked meats like bacon, ham, and brisket, hickory and oak are popular choices due to their rich, savory notes. Mesquite, while intense, is often used for beef and game meats. When it comes to smoked fish, such as salmon, alder and maple are preferred for their mild, slightly sweet smoke that enhances the natural flavors without overpowering them. For smoked cheese, lighter woods like apple, cherry, or pecan are recommended, as they provide a gentle smoke that complements rather than dominates the delicate dairy flavors. Understanding these wood types for smoking helps ensure the best results for each product category.

Flavor Enhance and Food Preservation Techniques in Smoking

How does smoking contribute to the long-term preservation of foods?

Smoking is a time-honored food preservation method that not only imparts distinctive flavors but also extends the shelf life of a wide range of products. The process works by exposing foods—such as meats, fish, cheeses, and even spices—to smoke generated from burning wood chips or sawdust. This smoke contains compounds that inhibit the growth of spoilage-causing bacteria and molds, while also reducing moisture content, which further slows down microbial activity. As a result, smoking for long-term preservation is a reliable strategy for maintaining both the safety and quality of foods over extended periods.

What techniques can enhance flavor retention in smoked foods?

Maximizing flavor retention during the smoking process requires careful control of several variables. Advanced equipment, such as BAK Food Equipment’s automated spiral smoking system, allows for precise regulation of temperature, humidity, and smoke density. This ensures that flavor infusion is consistent and deep, without over-drying or under-smoking the product. Processes like injection of curing solutions can further enhance how to preserve flavor in smoked foods by ensuring even distribution of seasonings. Additionally, using high-quality wood and maintaining optimal airflow in smoke chambers are critical for achieving rich, authentic smoke flavor while preserving the natural characteristics of the food.

How do smoking and curing work together to preserve and enhance food?

Smoking and curing are often used in tandem as part of comprehensive food enhancement and preservation methods. Curing typically involves the application of salt, nitrates, and other flavors to impart flavor and inhibit bacterial growth. When combined with smoking, the result is a synergistic effect: curing enhances and preserves the food while smoking adds an additional layer of protection and flavor complexity. This combination is especially effective in products like bacon, ham, and smoked fish, where both safety and taste are paramount. The integration of automated injectors and brine mixing and preparation systems with smoking systems, as offered by BAK Food Equipment, ensures that both smoking and curing processes are optimized for consistency, efficiency, and superior product quality.

Culinary Applications of Smoked Foods

What are the most popular culinary applications of smoked foods?

Smoked foods have long held a prominent place in global cuisine, celebrated for their distinctive flavors and aromas. Traditional dishes such as smoked meats—including bacon, ham, and sausages—are staples in many cultures, prized for their rich, savory profiles. Smoked fish, such as salmon and trout, are also widely enjoyed, offering a delicate balance of smokiness and natural seafood flavors. Beyond proteins, smoked cheese has become increasingly popular, adding depth to cheese boards, sandwiches, and salads. The versatility of smoked foods extends to alternative proteins and even smoked salts, which can be used as finishing touches to elevate a variety of dishes.

BAK Food Equipment — Experts in Industrial Smoking Systems

How does BAK support commercial food processors with advanced smoking solutions?

BAK Food Equipment is a trusted partner for commercial food processors seeking reliable, high-performance smoking systems. Our expertise lies in delivering industrial-grade solutions that combine efficiency, hygiene, and precision for large-scale smoked meat production, as well as for poultry, seafood, cheese, and plant-based proteins. BAK’s patent-pending automated spiral smoking lines and semi-continuous smoking/chilling systems are engineered to meet the rigorous demands of modern food processing automation, helping facilities streamline operations and maintain the highest standards of product quality.

What makes BAK’s smoking equipment stand out from traditional systems?

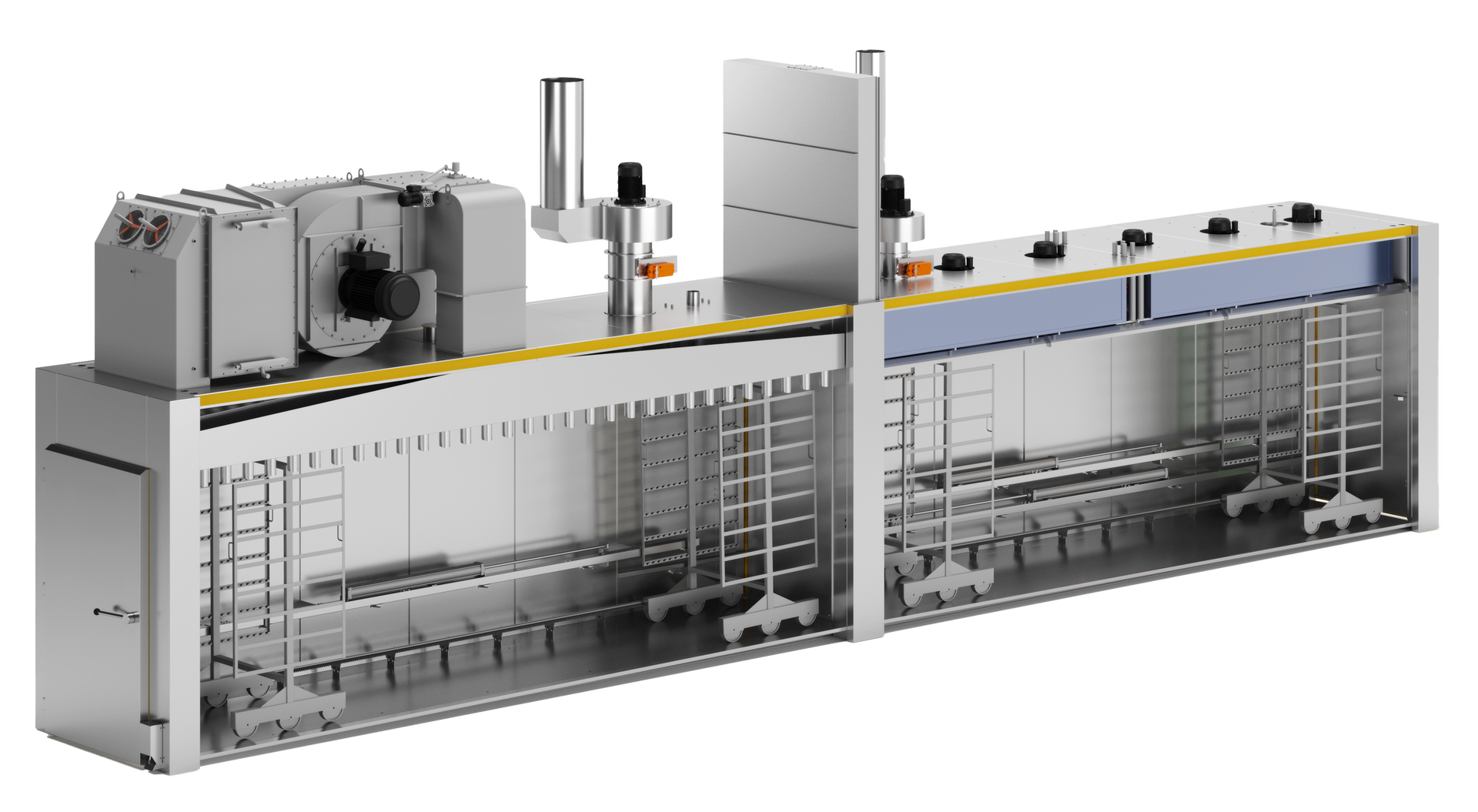

Unlike conventional industrial smokehouses, BAK’s automated smoking spiral system is designed for maximum throughput and minimal labor requirements. Our spiral smoking/cooking/chilling lines automate the entire process, from brine preparation and injection to tumbling, smoking, and chilling. This end-to-end automation not only reduces operational costs but also ensures consistent, repeatable results. Advanced programmable control systems allow for precise management of temperature, humidity, and smoke distribution, while energy-efficient heating and airflow technologies guarantee uniform smoke flavor and optimal product yields. These features make BAK’s equipment a game-changer for processors looking to upgrade from outdated smokehouses to state-of-the-art, automated production lines.

If you do not wish to make the switch to automated smoking spiral systems, BAK Food Equipment also offers state-of-the-art traditional smokehouses and semi-continuous smoke chambers.

How does BAK help facilities improve flavor consistency, yield, and efficiency?

BAK’s solutions are built to deliver authentic, rich smoke flavor while optimizing every aspect of the smoking process. Our systems ensure uniform smoke penetration and controlled drying, cooking, and chilling, resulting in products with consistent texture, color, and taste. By integrating key stages—such as brine mixing, injecting, tumbling, drying, smoking, and freezing—into a seamless, HACCP-compliant workflow, BAK helps processors maximize yield and minimize waste. Our team works closely with clients to customize systems for specific production goals, whether it’s scaling up smoked foods output, improving product consistency, or reducing labor costs. We encourage processors to explore our product line or schedule a meeting to discuss how BAK can tailor a solution to their unique needs, ensuring they stay ahead in a competitive market.

Key Takeaways of Smoking in Food Processing

How does smoking as a food processing technique enhance culinary experiences?

Smoking in food processing is a time-honored culinary technique that not only preserves food but also infuses it with distinctive flavors and aromas. By exposing food to controlled smoke, producers can achieve a depth of flavor and texture that is difficult to replicate with other methods. Whether it’s the robust smokiness of bacon, the delicate notes in smoked salmon, or the complexity added to cheeses and alternative proteins, smoking elevates the sensory experience of food. Modern advancements, such as BAK Food Equipment’s automated spiral smoking systems, allow for precise control over temperature, humidity, and smoke density, ensuring consistent, high-quality results across a wide range of products.

What are the key takeaways regarding the use of smoking for flavor enhancement and preservation?

The primary benefits of smoking in food processing are twofold: preservation and flavor infusion. Smoking acts as a natural preservative by reducing moisture and inhibiting the growth of spoilage organisms, extending the shelf life of meats, fish, and other products. At the same time, the process imparts a unique smoke flavor profile that enhances the appeal of both traditional and innovative foods. The choice of wood, smoking technique (hot or cold), and equipment all play critical roles in determining the final product’s quality. BAK Food Equipment’s solutions, such as their smoke chambers and automated spiral systems, are designed to optimize these variables, allowing producers to consistently deliver products with superior taste and extended freshness.